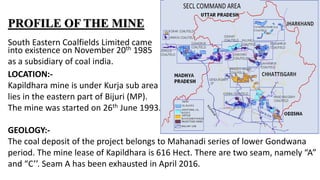

1) The document describes a continuous miner used at the Kapildhara mine in India.

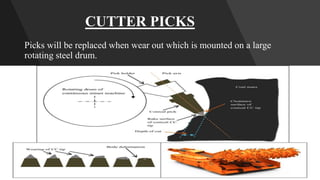

2) The continuous miner is a Komatsu Joy 12CM15 model that was commissioned in 2008 and uses a cutting drum with tungsten carbide picks to continuously extract coal from the working face.

3) It can extract coal at a high rate of up to 30 tonnes per minute and was being used to extract coal from a 1.5-4.8 meter thick seam at the Kapildhara mine.