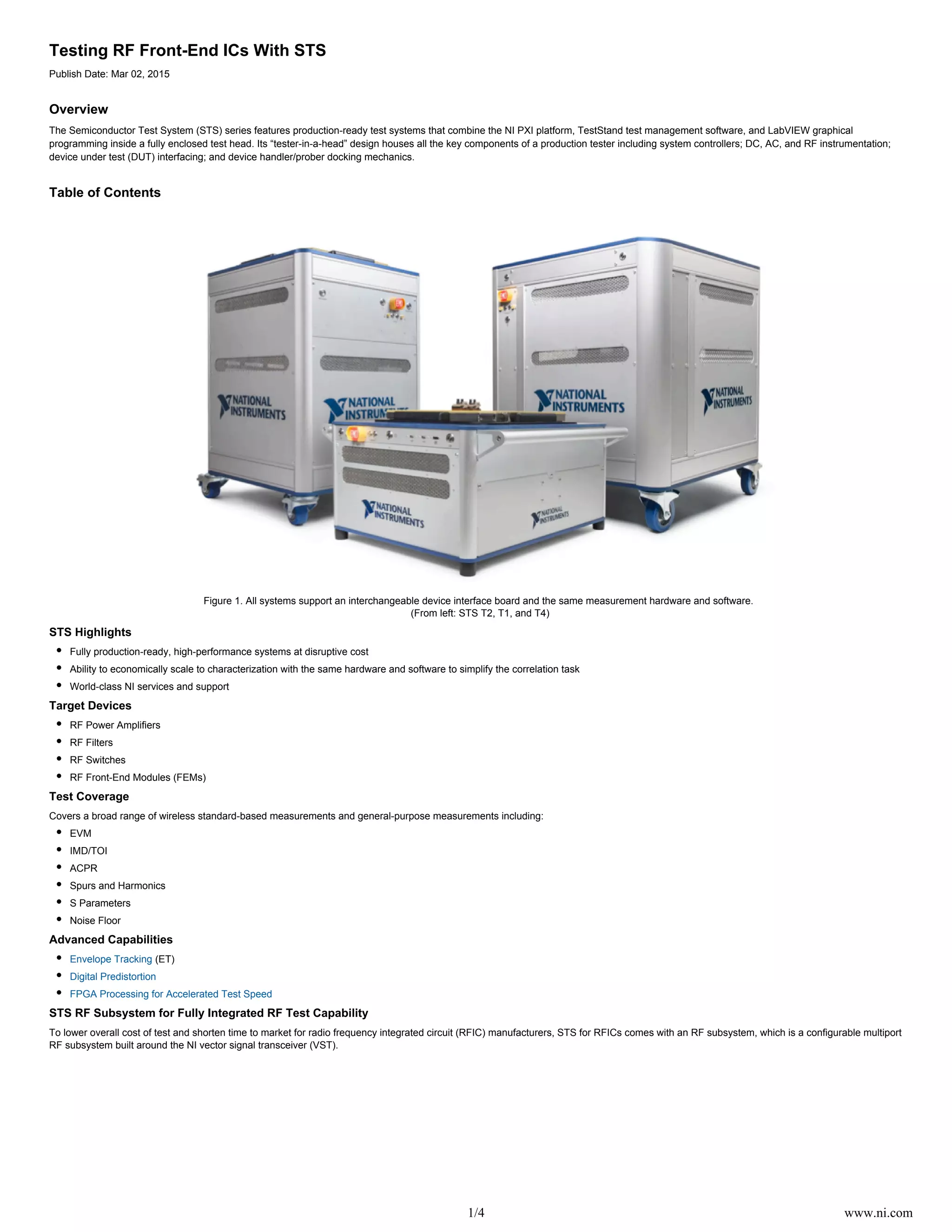

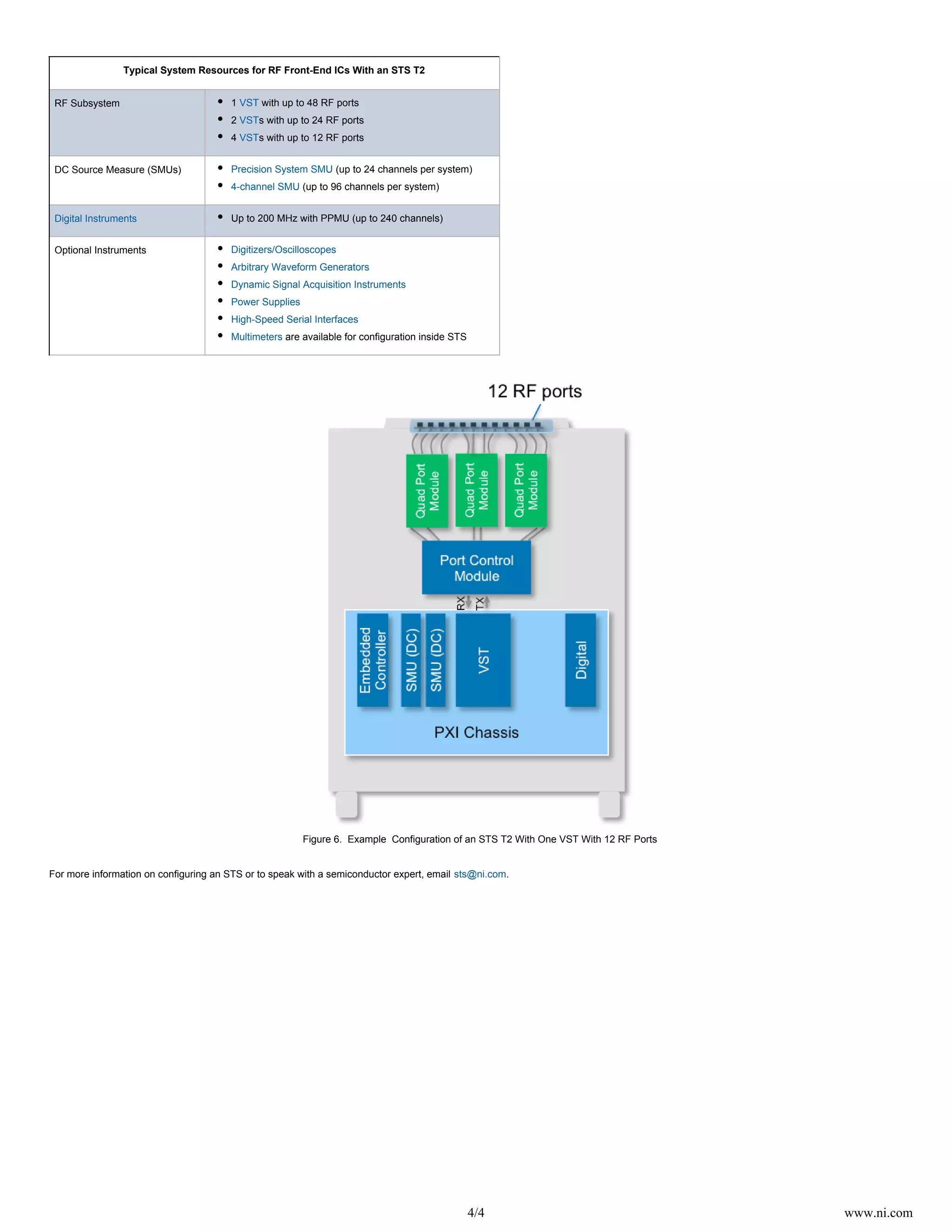

The Semiconductor Test System (STS) provides fully integrated RF test capability for testing RF front-end ICs with production-ready test systems. The STS combines NI's PXI platform, TestStand software, and LabVIEW inside an enclosed test head for RF measurements. Key features include a configurable multiport RF subsystem built around the NI vector signal transceiver for integrated RF testing, flexibility to scale from characterization to production, and world-class support from NI.