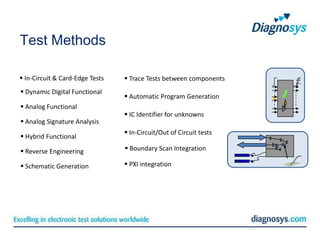

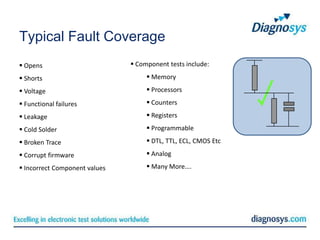

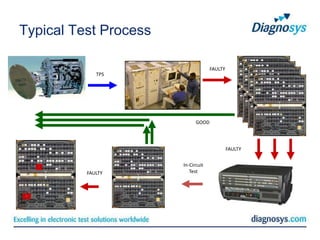

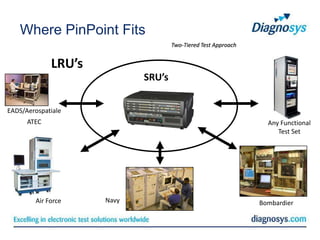

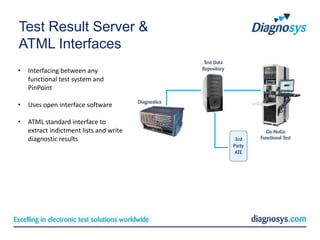

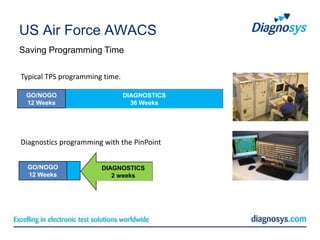

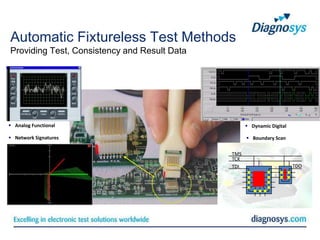

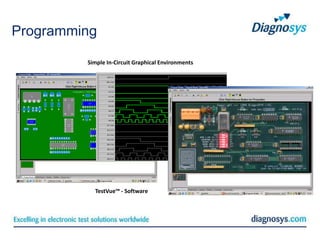

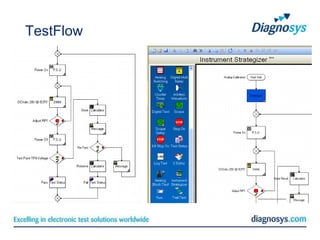

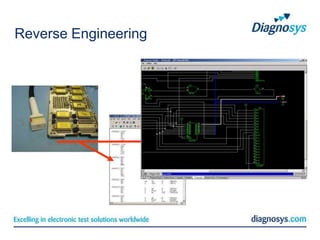

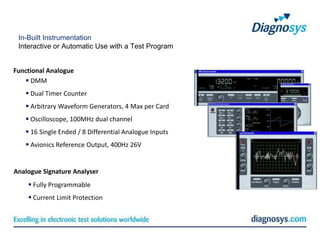

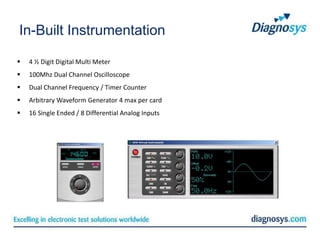

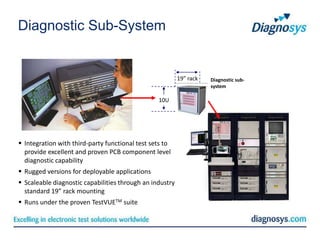

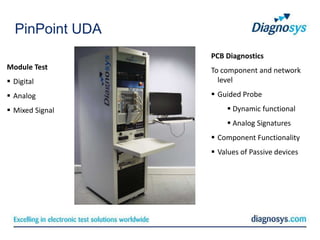

The PinPoint system provides benchtop diagnostic testing of printed circuit boards. It offers fixtureless testing through multiple strategies like in-circuit, impedance signatures, and reverse engineering. PinPoint can rapidly diagnose faults down to the component level. It features various test methods like in-circuit, analog functional, and analog signature analysis. PinPoint integrates with functional test systems and has typical fault coverage including opens, shorts, voltage, and functional failures. It provides automated diagnostic programming to reduce time to identify issues.