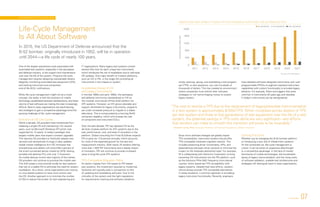

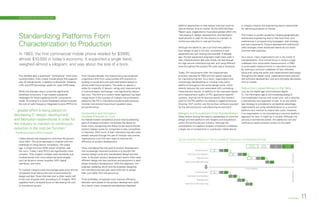

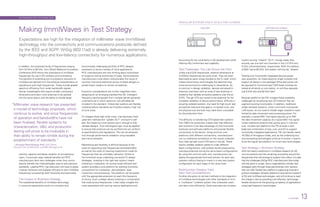

This document discusses trends in automated test systems and strategies. It covers topics like harvesting production test data through real-time analytics, challenges of life-cycle management for long-term projects due to software obsolescence and compatibility issues, and how off-the-shelf test executives can help address the influx of new programming languages. It also discusses standardizing platforms across product design cycles to reduce costs, and adopting modular solutions to validate high-frequency components economically.