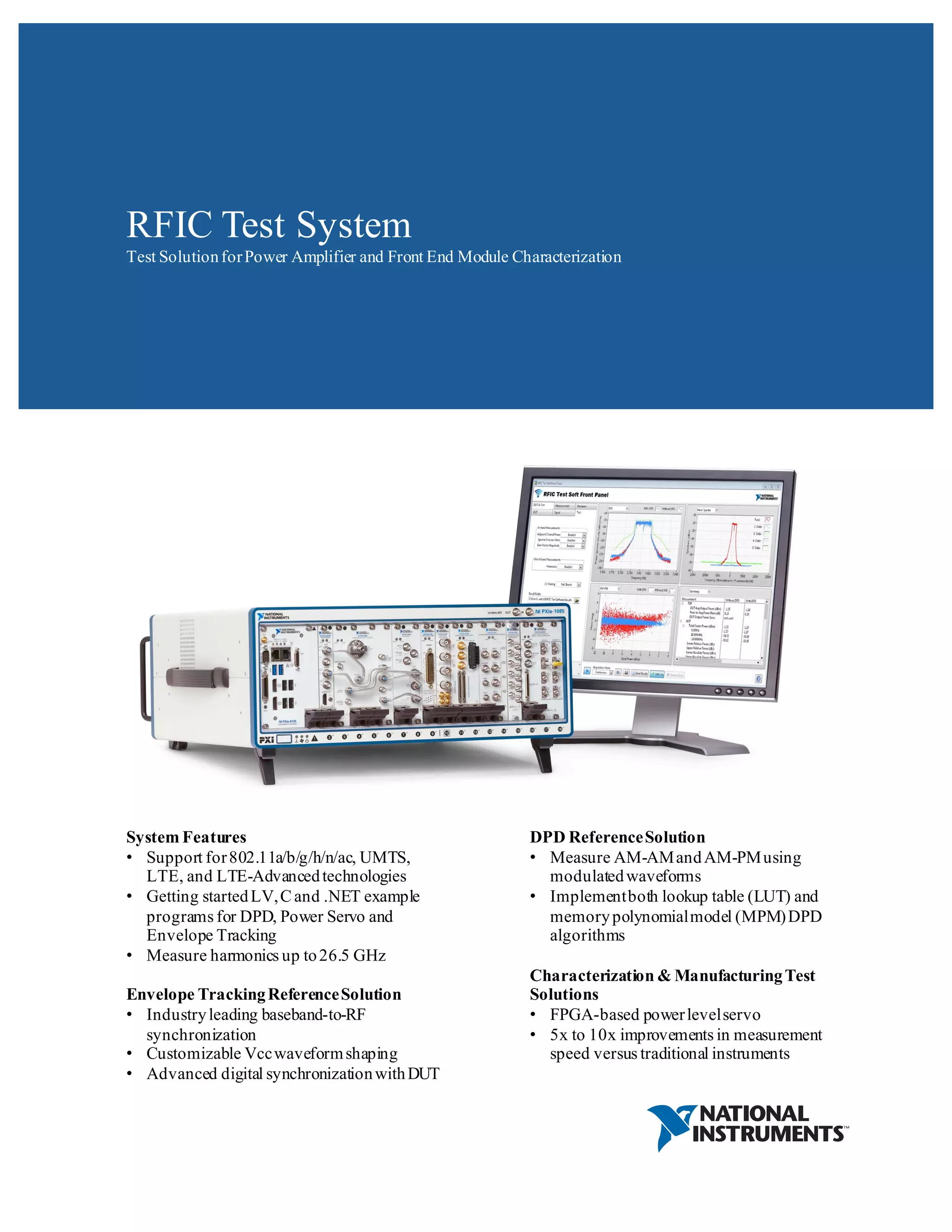

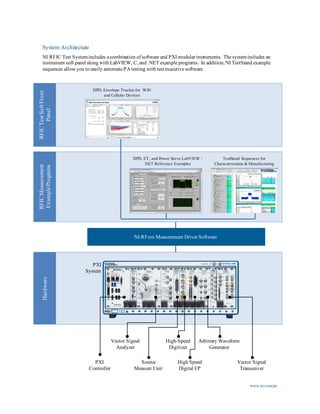

The document describes an RFIC test system from NI for characterizing and testing power amplifiers and front-end modules. The system provides solutions for digital pre-distortion, envelope tracking, and power amplifier characterization. It uses PXI modular instruments along with application software and example programs to automate testing of power amplifiers.

![©2013 National Instruments. All rights reserved. LabVIEW, National Instruments, NI, ni.com, and NI CompactDAQ are trademarks of National

Instruments. Other product and companynames listedare trademarksor trade names

of their respective companies. [20160729]

For more informationonthe RFIC Test system, email: rfic.test@ni.com](https://image.slidesharecdn.com/3e0e0832-b87c-4146-9e22-2edd423ad2ac-170104215533/85/STS-RF-IC-Test-System-12-320.jpg)