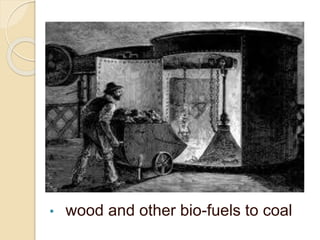

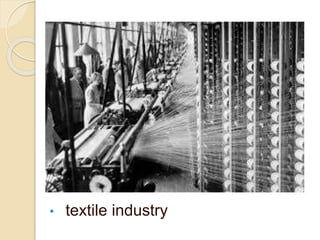

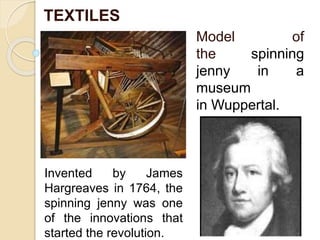

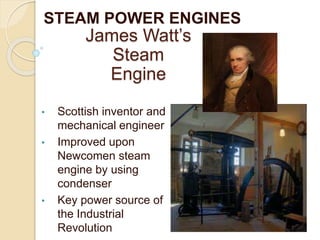

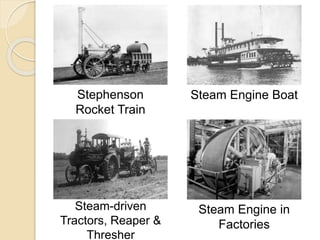

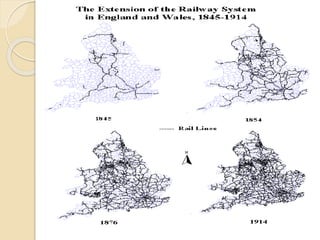

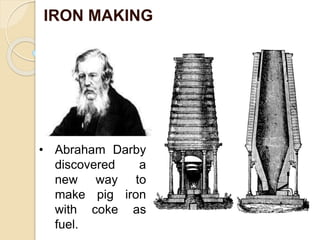

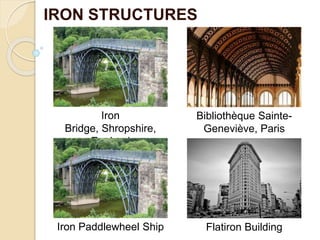

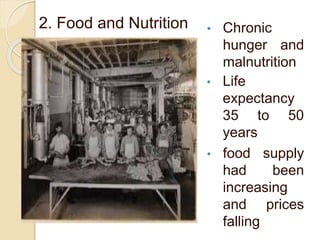

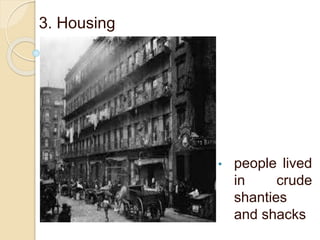

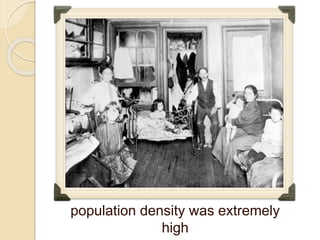

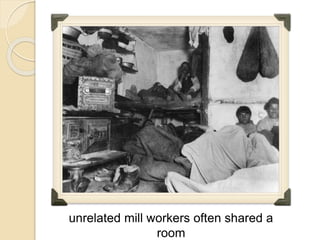

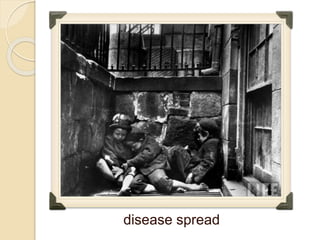

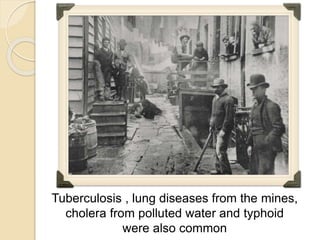

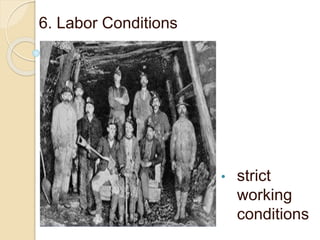

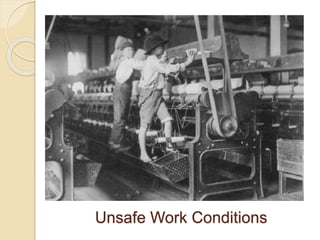

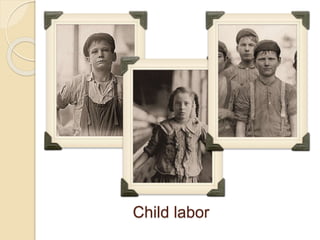

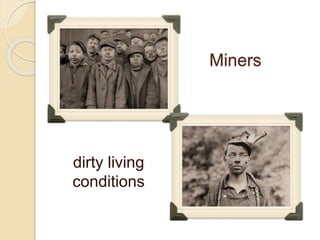

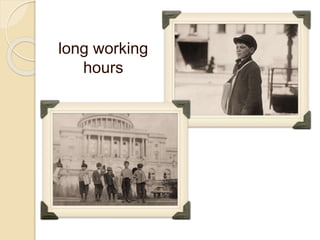

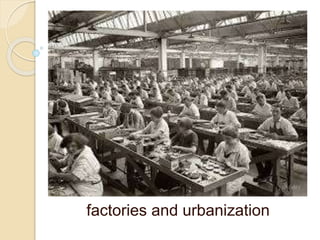

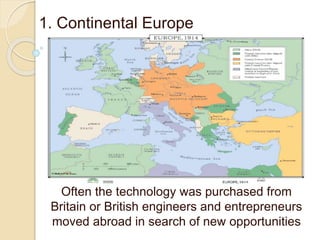

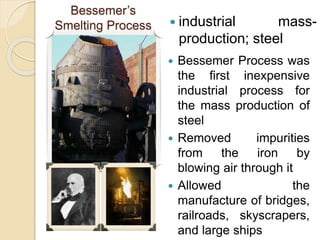

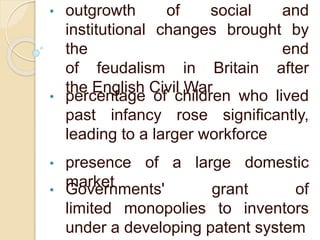

The Industrial Revolution, spanning from 1760 to the early 1840s, marked a significant shift from hand production methods to machine-driven manufacturing, notably in textiles and iron production, driven by innovations like steam power and the spinning jenny. While the revolution improved productivity and introduced new technologies, it also led to severe social challenges such as poor living conditions, labor exploitation, and health issues among the rapidly growing population. The effects of industrialization extended beyond Great Britain, influencing economies in Europe, the United States, and Japan, with advancements in steel, chemical industries, and the rise of mass production in the second industrial revolution.