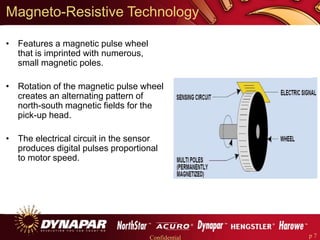

The document provides an overview of encoder basics, including definitions, types, sensing technologies, and mechanical designs. Key encoder types covered are incremental, absolute, and resolver, with descriptions of their applications and technologies such as magnetic and optical. The document also discusses different mounting styles and costs associated with each encoder type, highlighting their advantages and ideal usage scenarios.