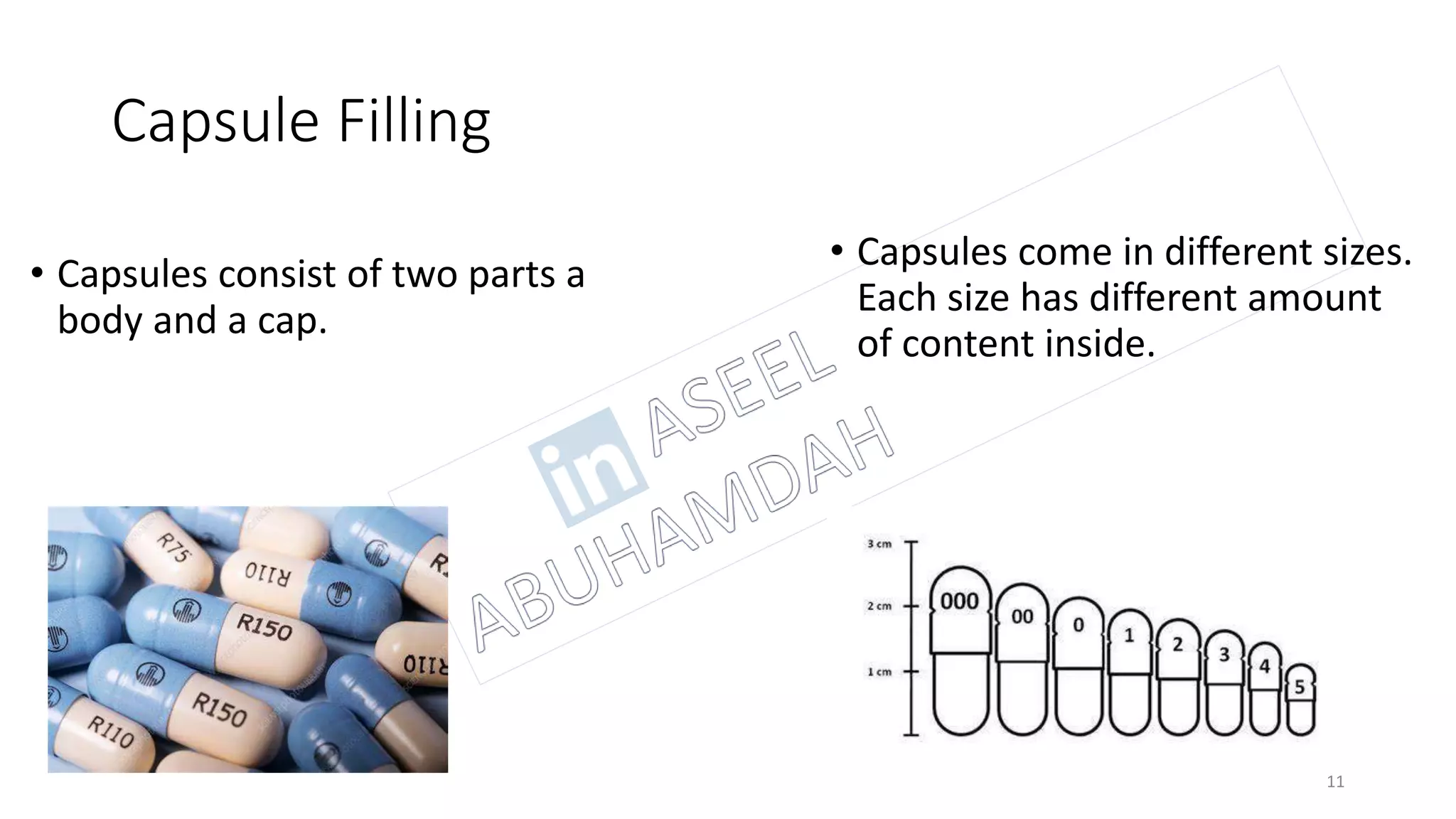

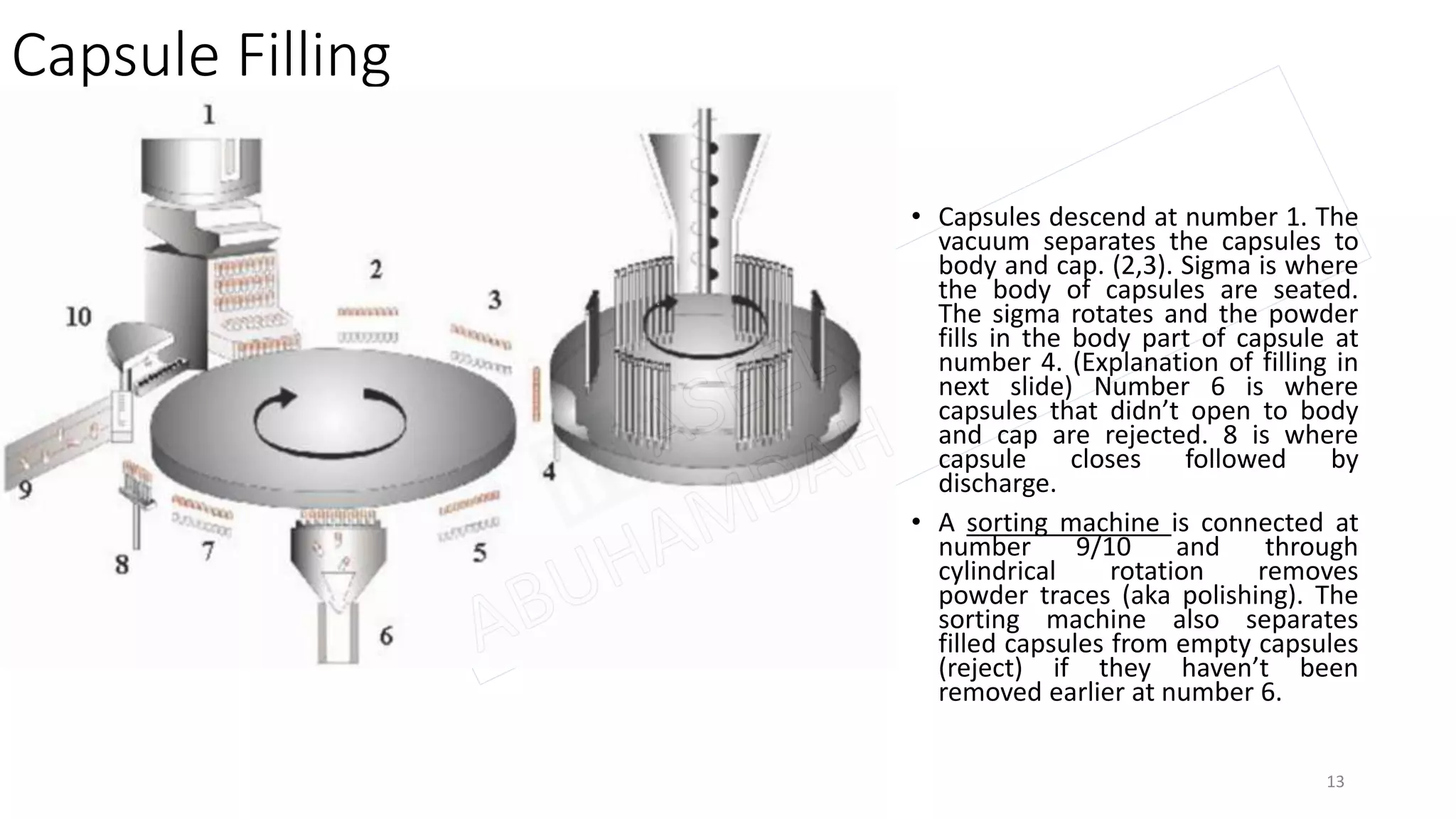

The document discusses granulation and capsule filling processes in the pharmaceutical industry, highlighting the importance of granules for uniform density and improved flowability during manufacturing. It details the tableting mechanism, including components such as punches, dies, and the adjustments made to ensure proper tablet production. Additionally, the capsule filling process is outlined, explaining how capsules are separated, filled with powder, and sorted for quality control.