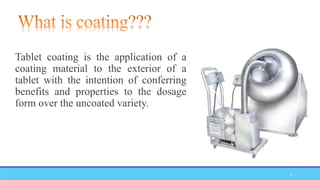

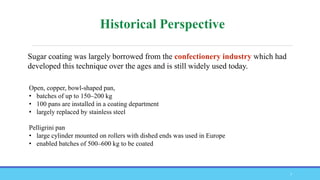

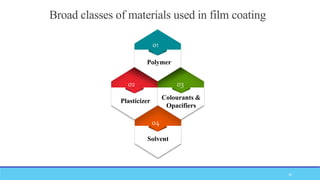

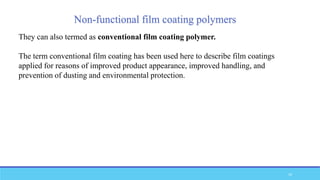

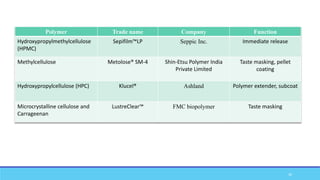

The document discusses tablet coating processes, emphasizing the importance of both sugar and film coatings for enhancing tablet properties like appearance, taste masking, and controlled release. It outlines the stages and materials involved in sugar and film coating, including the benefits and challenges of each method, as well as the characteristics of various polymers used in film coatings. Overall, it highlights the evolution of coating techniques and their significance in pharmaceutical formulations.

![[1] Shellac

This is a purified resinous secretion of the insect Laccifer lacca, indigenous to

India.

Solubility: Shellac is insoluble in water but shows solubility in aqueous alkalis; it

is moderately soluble in warm ethanol.

Problems:

material of natural origin and consequently suffers from occasional supply problems

quality variation

stability problems associated with increased disintegration and dissolution times on

storage.

Polymer Trade name Function

Shellac EmCoat 120 N

MarCoat 125

Enteric coat

11](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-11-320.jpg)

![[2] Zein

It is a protein contained in the endosperm tissue of Zea mais occurs as by product

of corn processing.

Solubility: soluble in alcohol.

Polymer Trade name Function

Zein G200 Enteric coat

12](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-12-320.jpg)

![[1] Acrylic Polymer/ methacrylate aminoester copolymer

Insoluble in water

Soluble in Acidic medium having pH <4

Solubility in neutral and alkaline medium is achieved by swelling and

increased permeability to aqueous medium.

Complete disintegration and dissolution of film can be assured by

incorporation of soluble polymers such as cellulose ethers, starch.

Polymer Trade name Company Function

Copolymers of acrylate and

methacrylates with quarternary

ammonium group in

combination with sodium

Carboxymethylcellulose

Eudragit RD 100 Evonik Rapidly disintegrating

34](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-34-320.jpg)

![[2] Cellulose derivatives

Majority of these polymers used in film coating are ethers of cellulose.

Polymer chain length together with size and extent of branching will

determine the viscosity of polymer solution.

Polymer Substituent Solubility Other properties

HPMC (Hydroxy Propyl

Methyl Cellulose)

-CH3-CH2-CH(OH)-CH3 Soluble in both aqueous and

organic solvents

• Non-tackiness

• Flexible strong film

Hydroxy ethyl cellulose -CH(OH)-CH3 Soluble in water,

Insoluble in organic solvents

Hydroxy propyl

cellulose

—CH2 —CH(OH)—CH3 Soluble in aqueous and

alcoholic media.

• Tackiness

• Weak film

Methyl cellulose -CH3 It has LCST 40-50˚C.

Readily soluble in water below

it’s LCST.

Rarely used in film coating due to

lack of commercial availability of

low viscosity material meeting

appropriate compebdial

requirements

35](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-35-320.jpg)

![[1] Methacrylate ether copolymer

Completely esterified with no free carboxylic acid group.

Neutral in nature and insoluble over entire physiological pH.

Become swell and permeable to water and dissolve substances thus used in

modified release formulation, e.g. Eudragit

Extended release coating polymer

Polymer Trade name Company Function

Copolymers of

acrylate and

methacrylates with

quarternary

ammonium group.

Insoluble, High permeability:

Eudragit® RL PO, Eudragit® RL,

Eudragit® RL 30D

Insoluble,Low Permeability:

Eudragit® RSPO, Eudragit® RS

30D

Evonik Sustained release

38](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-38-320.jpg)

![[2] Ethyl Cellulose

High substitution of cellulose make it insoluble in water.

The polymer is not usually used on its own but normally in combination with

secondary polymers such as HPMC etc.

Ideal polymer for modified release coating due to following properties:

Odourless

Tasteless

High degree of stability (both under physiological conditions and normal

storage condition)

Good solubility in common solvents used in coating.

Polymer Trade name Company Function

Ethyl cellulose Aquacoat® ECD FMC Sustained release

Surelease® Colorcon

39](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-39-320.jpg)

![Enteric coating polymer

[1] Methacrylic acid copolymer

These polymer possess free carboxylic acid group.

They form salt with alkalis and having solubility at pH in excess of 5.5

Depending on the degree of substitution with carboxylic group they have

different pH-dissolution profile.

Specific name Monomers Trade name Marketed form

Poly(methylacrylate,

ethylacrylate)

copolymer of MA and EA in a

molar ratio of 1:1

Eudragit L30D 30% aqueous dispersion

Eudragit L100-55 Powder

Poly(methacrylic acid,

methylmethacrylate)

copolymer of MA and MMA

in a molar ratio of 1:1

Eudragit L12.5 12.5% solution in isopropanol

Eudragit L100 Powder

Poly(methacrylic acid,

methylmethacrylate)

copolymer of MA and MMA

in a molar ratio of 1:2

Eudragit S12.5 12.5% solution in isopropanol

Eudragit S100 Powder

40](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-40-320.jpg)

![[2] Cellulose esters

Polymer Substituent Solubility Other properties Trade name

Cellulose acetate

phthalate (CAP)

-CO-CH3, CO-C6H4-COOH Insoluble in water &

alcohol

• Oldest and widely

used enteric coat.

• Prone to hydrolysis

Aquacoat CPD®,

C–A–P NF

Eastman

Cellulose acetate

trimellitate (CAT)

-CO-CH3,-CO-C6H3-

(COOH)2

Start to dissolve at low

pH 5.5 thus efficient

dissolution in upper

small intestine

Chemically resembles

CAP but have

additional -COOH

group

Hydroxy propyl

methyl cellulose

phthalate (HPMCP)

-CH3,-CH2CH(OH)CH3,-

CO-C6H4-COOH

Insoluble in water but

soluble in aqueous

alkalis & acetone/water

95:5 mixture

More flexible polymer InstacoatTM EN-

HPMCP

41](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-41-320.jpg)

![Solid dosage form may be incorporated with several special materials such as:

[1] Flavours and sweeteners are added to mask unpleasant odours or to develop the taste. e.g., fruit

spirits (organic solvent), aspartame, water soluble pineapple flavour.

[2] Surfactants are ancillary to stabilize immiscible or insoluble ingredients in the coating. They

facilitate substrate wettability and promote coalescence of polymeric material over the substrate’s

surface e.g., Spans, Tweens etc.

[3] Antioxidants are incorporated to stabilize a dye system to oxidation and colour change e.g.,

oximes, phenols etc.

[4] Antimicrobials are added to inhibit microbial growth in the coating composition. Various

cellulosic materials are mainly prone to microbial growth and they can not be stored in solution

form e.g., Carbamates, alkylisothiazloinone, benzothiazoles etc.

MiscellaneousCoating Solution Components

53](https://image.slidesharecdn.com/finalcoatingassignment-220708200703-6d2938a6/85/Coating-of-Pharmaceutical-Tablet-53-320.jpg)