Surface grinding and accessories

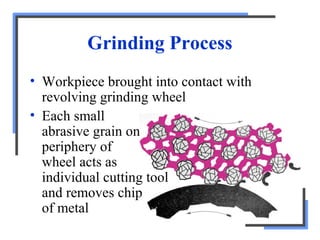

- 1. Grinding Process • Workpiece brought into contact with revolving grinding wheel • Each small abrasive grain on periphery of wheel acts as individual cutting tool and removes chip of metal

- 2. General Rules for Grinding 1. Use silicon carbide wheel for low-tensile- strength material and aluminum oxide wheel for high-tensile-strength materials 2. Use hard wheel on soft materials and soft wheel on hard materials 3. If wheel too hard, increase speed of work or decrease speed of wheel to make it act as softer wheel

- 3. 4. If wheel appears too soft or wears rapidly, decrease speed of work or increase speed of wheel 5. Glazed wheel will affect finish, accuracy, and metal-removal rate. • Main causes of wheel glazing are: • Wheel speed too fast • Work speed too slow • Wheel too hard • Grain too small • Structure too dense

- 4. 6. If wheel wears too quickly, cause may be any of the following: 1. Wheel too soft 2. Wheel speed too slow 3. Work speed too fast 4. Feedrate too great 5. Face of wheel too narrow 6. Surface of work interrupted by holes or grooves

- 5. Surface Grinding • Refers to production of flat, contoured, and irregular surfaces on piece of work – Passed against revolving grinding wheel • Four distinct types of surface grinding machines – Horizontal spindle grinder, reciprocating table – Horizontal spindle grinder, rotary table – Vertical spindle grinder, reciprocating table – Vertical spindle grinder, rotary table

- 6. Horizontal Spindle Reciprocating Table Surface Grinder • Most commonly used • Either hand or hydraulically operated • EZ-SURF® Grinder – TEACH mode: operator can teach and program up to 100 points for X and Z coordinates – "Intelligent DRO": helps increase productivity, improve accuracy and simplify grinding operations

- 7. Parts of a Hydraulic Surface Grinder • Base – Generally heavy cast-iron construction – Usually contains hydraulic reservoir and pump to operate table and power feeds • Saddle – Moved in or out across ways, manually or auto • Table – Mounted on top of saddle – Ways for table at right angles to those on base

- 8. • Column – Mounted on back of frame – Contains ways for spindle housing and wheelhead – Wheelfeed handwheel provides means of moving wheelhead vertically to set depth of cut • Table traverse handwheel or hydraulic control valve lever – Means to control manually the reciprocating action of table

- 9. • Stop dogs – Mounted on side of table – When strike table traverse reverse lever the direction of table reversed • Crossfeed handwheel – Manual means for table to be fed toward or away from column • Power crossfeed control – Automatic means for table to be fed toward or away from column

- 10. 81-10 Guidelines for Grinding Wheel Care 1. When not in use, store properly 2. Should be tested for cracks prior to use 3. Select proper type wheel for job 4. Should be properly mounted and operated at recommended speed

- 11. 81-11 Procedure for Mounting a Grinding Wheel 1. Test wheel to see that it is not cracked by ring testing with handle of screwdriver 2. Clean grinding wheel adapter 3. Mount adapter through wheel and tighten threaded flange 1. Place blotter on each side prior to mounting 2. Should be good fit on adapter or spindle 3. Diameter of flanges not less ½ wheel diameter 4. Tighten adapter flanges so holds firmly

- 12. Two Methods of Balancing a Wheel 1. Static balancing • Wheel balance off machine with use of balancing stand and arbor • Counterweights in wheel flange must be correctly positioned in order to balance 1. Dynamic balancing • Automatically balanced wheel while revolving using ball-bearing balancing devices on machine

- 13. Procedure To Balance a Grinding Wheel 1. Mount wheel and adapter on surface grinder and true wheel with diamond dresser 2. Remove wheel assembly and mount special tapered balancing arbor in hole of adapter 3. Place wheel and arbor on balancing stand that has been leveled

- 14. 4. Allow wheel to rotate until it stops 5. Rotate wheel and stop it at three positions: one-quarter, one-half, and three-quarters of a turn to check balance 6. Loosen setscrews in wheel counterbalances, in grooved recess of flange, and move counterbalances opposite chalk mark 7. Check wheel in four positions (Steps 4, 5)

- 15. 8. Move counterbalances around groove equal amount on each side of centerline and check for balance again 9. Continue to move balances away from heavy side until wheel remains stationary at any position 10. Tighten counterbalances in place

- 16. Grinder Safety 1. Use the right wheel 2. Ring test the wheel before mounting 3. Always use mounting blotters 4. Tighten clamping nuts only enough to prevent wheel from slipping 5. Be sure flanges are flat and free from burrs and gouges

- 17. 6. Check arbor holes – wheel should slip freely, not loosely, onto spindle arbor 7. Do not exceed maximum speed 8. Always use wheel guard supplied 9. Stand to one side whenever wheel started 10. Always wear safety glasses when grinding

- 18. Truing a Grinding Wheel • Process of making grinding wheel round and concentric with its spindle axis and producing required form of shape on wheel – Involves grinding of a portion of the abrasive section of grinding wheel

- 19. Dressing a Grinding Wheel • Operation of removing dull grains and metal particles • Exposes sharp cutting edges so cuts better • Reasons for dressing wheel – Reduce heat generated between work and wheel – Reduce strain on grinding wheel and machine – Improve surface finish and accuracy of work – Increase rate of metal removal

- 20. Procedure To True and Dress a Grinding Wheel 1. Check diamond for wear and if necessary, turn it in holder to expose sharp cutting edge 2. Clean magnetic chuck thoroughly with cloth 3. Place piece of paper on left-hand end of magnetic chuck 4. Place diamond holder on paper and energize chuck

- 21. 5. Raise wheel above height of diamond 6. Move table longitudinally so diamond is offset approximately ½ in. to left of centerline of wheel 7. Adjust table laterally so diamond is positioned under high point on face of wheel 8. Start wheel revolving and carefully lower wheel until high point touches diamond

- 22. 9. Move table laterally, using crossfeed handwheel to feed diamond across face of wheel 10.Lower grinding wheel about .001 to . 002 in. per pass • Rough-dress face of wheel until flat and dressed all around circumference 9. Lower wheel .0005 in. and take several passes across face of wheel

- 23. Helpful Ideas When Truing or Dressing Grinding Wheels 1. To minimize wear on diamond, rough- dress with abrasive stick 2. If coolant to be used during grinding, use coolant when dressing wheel 3. Loaded wheel indicated by discoloration of periphery or face – remove completely 4. If rapid removal of metal more important than surface finish, do NOT finish-dress

- 24. Work-Holding Devices • Work must be held in vise, held on V-blocks or bolted directly to table for some surface- grinding operations • Most of ferrous work ground on surface grinder held on magnetic chuck – Clamped to table of grinder

- 25. Two Types Magnetic Chucks • Electromagnetic chuck – Uses electromagnets to provide holding power – Advantages • Holding power may be varied to suit area of contact • Special switch neutralizes residual magnetism in chuck • Permanent magnetic chuck – Holding power provide by means of permanent magnets

- 26. Permanent Magnetic Chuck Construction • Base plate – Provides base for chuck and means of clamping it to table of grinder • Grid (magnetic pack) – Houses magnets and grid conductor bars – Moved longitudinally by handle • Case – Houses grid assembly, permits longitudinal movement, and provides oil reservoir for lubrication

- 27. • Top plate – Contains inserts or pole pieces separated magnetically from surrounding plate by means of white metal • Necessary to conduct magnetic lines of flux – Work place on face of chuck (top plate) and handle moved to on position, grid conductors bars and inserts in line • Permits magnetic flux to pass through work – Handle rotated 180º to off position • Moves bars and inserts out of line so work not held

- 28. Magnetic Chuck Accessories • Holding power of magnetic chuck dependent of size of workpiece, area of contact, and thickness of workpiece • Adapter plate used to securely hold thin work (less than ¼ in.) • Magnetic chuck blocks provide means of extending flux paths to hold workpieces that cannot be held securely on chuck face

- 29. How to Make Magnetic Chuck Blocks Last Longer 1. Clean thoroughly before and after use 2. Store in covered wooden box 3. Check frequently for accuracy and burrs 4. If regrinding necessary to restore accuracy, take light cuts with dressed wheel

- 30. More Work-Holding Devices • Sine Chuck – Use when required to grind angle on work – Form of magnetic sine plate • Double-faced tape – Used for holding thin, nonmagnetic pieces on chuck for grinding – Two adhesive sides: places between chuck and work

- 31. More Work-Holding Devices • Magna-vise clamps – Used when workpiece does not have large bearing area on chuck or work nonmagnetic – Consist of comblike bars attached to solid bar by piece of spring steel – Work placed on chuck surface between toothed edges • Special fixtures – Used to hold nonmagnetic and odd-shaped work

- 32. Four Purposes of Grinding Fluids 1. Reduction of grinding heat 2. Lubrication 3. Removal of swarf from cutting area • Small metal chips and abrasive grains 1. Control of grinding dust

- 33. Types of Grinding Fluids 1. Soluble oil and water • Milky solution applied by flooding surface 1. Soluble chemical grinding fluids and water • Used with "through-the-wheel" systems • Contains rust inhibitors and bactericides 1. Straight oil grinding fluids • Applied by flood system and used for high finish, accuracy and long wheel life

- 34. Methods of Applying Coolants • Flood system – Coolant directed onto work by nozzle and recirculated through system • Through-the-wheel cooling – Fluid pumped and discharged into dovetailed groove in wheel flange (with holes), fluid forced through wheel by centrifugal force • Mist cooling system – Atomizer principle: air passes through line, as passes reservoir draws coolant and discharges it in vapor form directed at point of contact

- 35. Factors Affecting Surface Finish • Material being ground • Amount of material being removed • Grinding wheel selection • Grinding wheel dressing • Condition of machine • Feed