Embed presentation

Downloaded 1,118 times

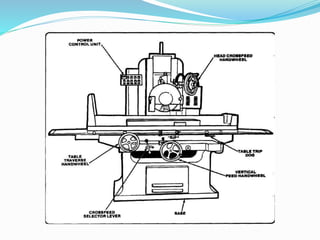

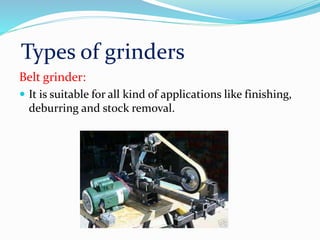

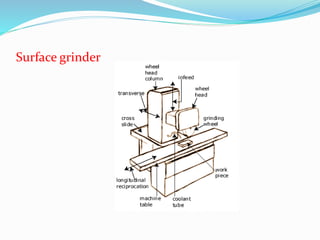

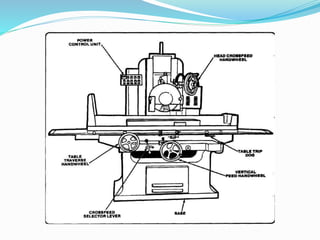

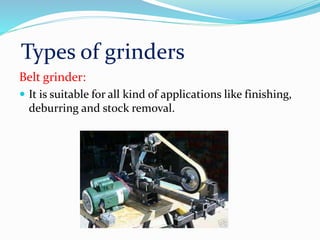

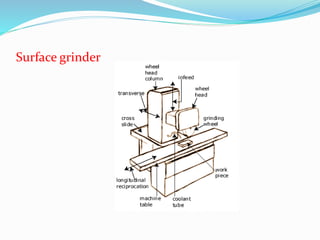

Grinding is a process that uses abrasive wheels to remove material from a workpiece through grinding wheels. It provides a good surface finish with less wheel wear and avoids grinding cracks or burns. The grinding machine consists of a powered grinding wheel and a fixture to hold the workpiece while coolant cools it. There are several types of grinders including belt grinders for various applications, bench grinders with two wheels, and cylindrical and surface grinders. Grinding is used for flat, conical and cylindrical surfaces, finishing bores, sharpening tools, and removing projections from castings. It supports work rigidly and provides high productivity with less needed skill and no deflection. However, it has trouble with varying