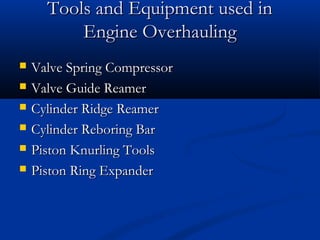

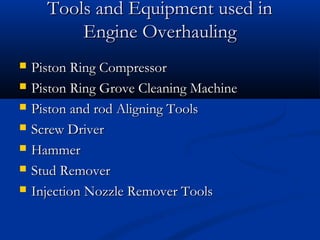

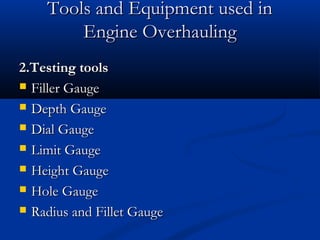

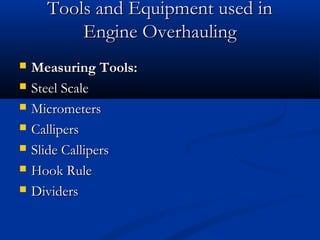

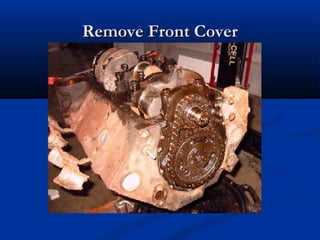

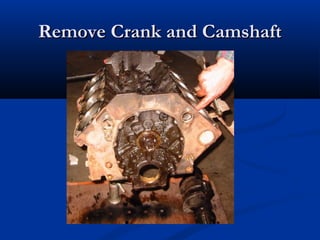

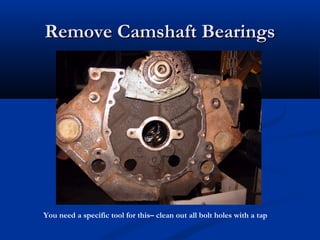

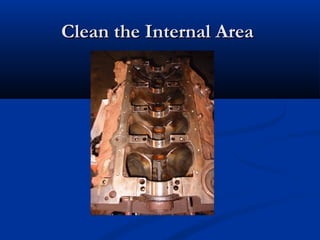

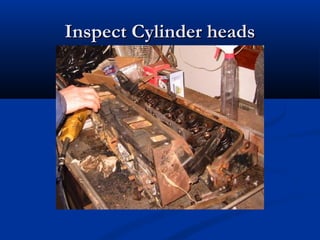

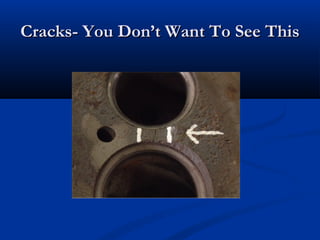

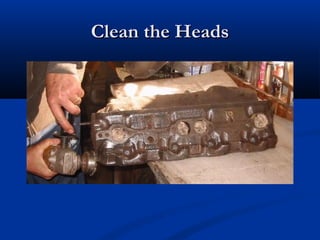

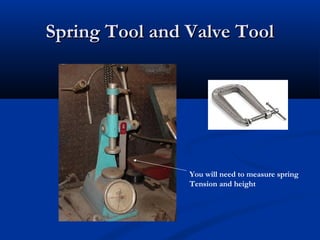

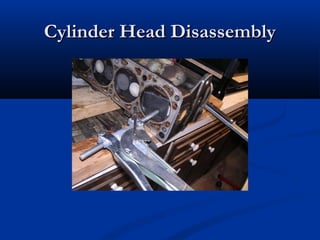

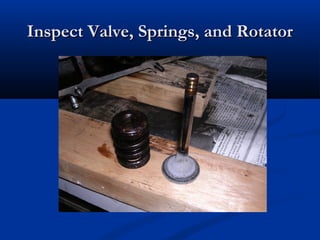

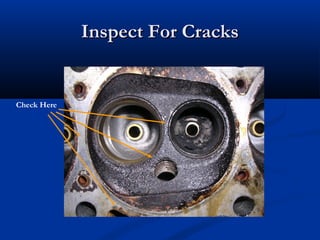

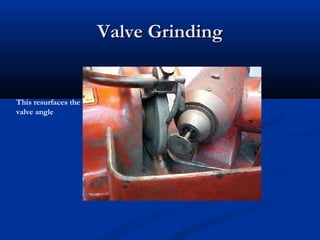

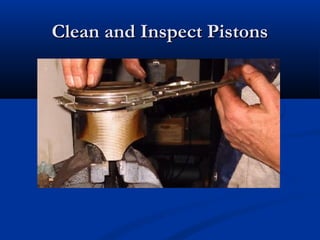

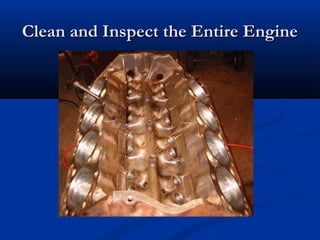

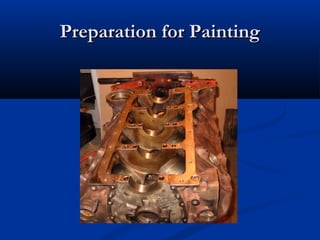

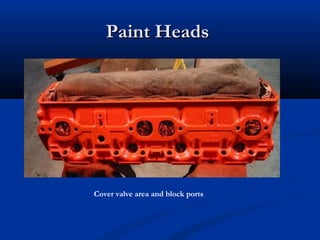

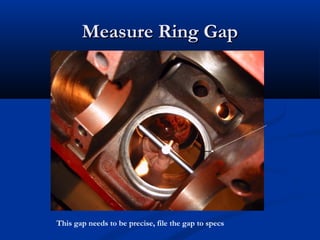

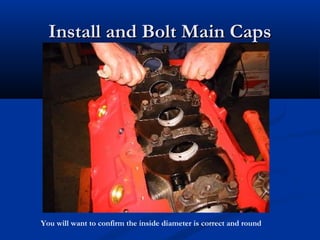

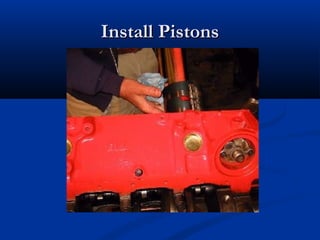

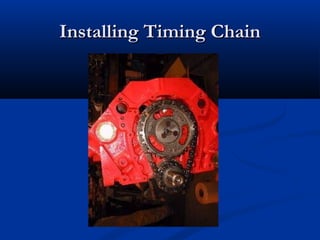

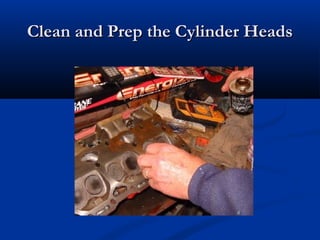

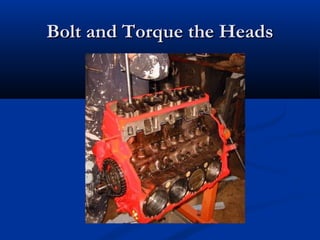

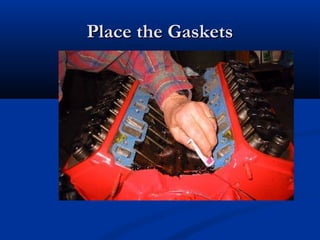

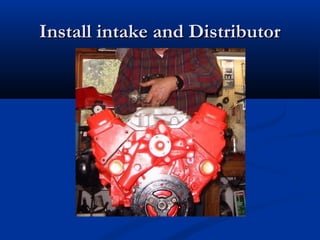

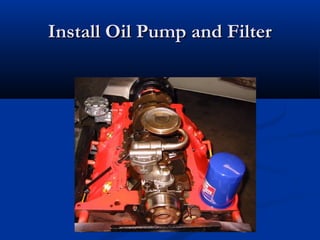

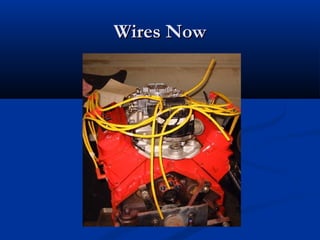

Engine service and overhauling involves regularly maintaining a vehicle's engine through procedures like replacing parts. Overhauling specifically involves completely disassembling the engine, testing and replacing components as needed, and reassembling it to improve performance and longevity. The process requires various tools and involves carefully removing, inspecting, cleaning, measuring, and reinstalling all engine parts to factory specifications. Proper service and overhauling helps prevent sudden engine failures and keeps it functioning optimally for longer.