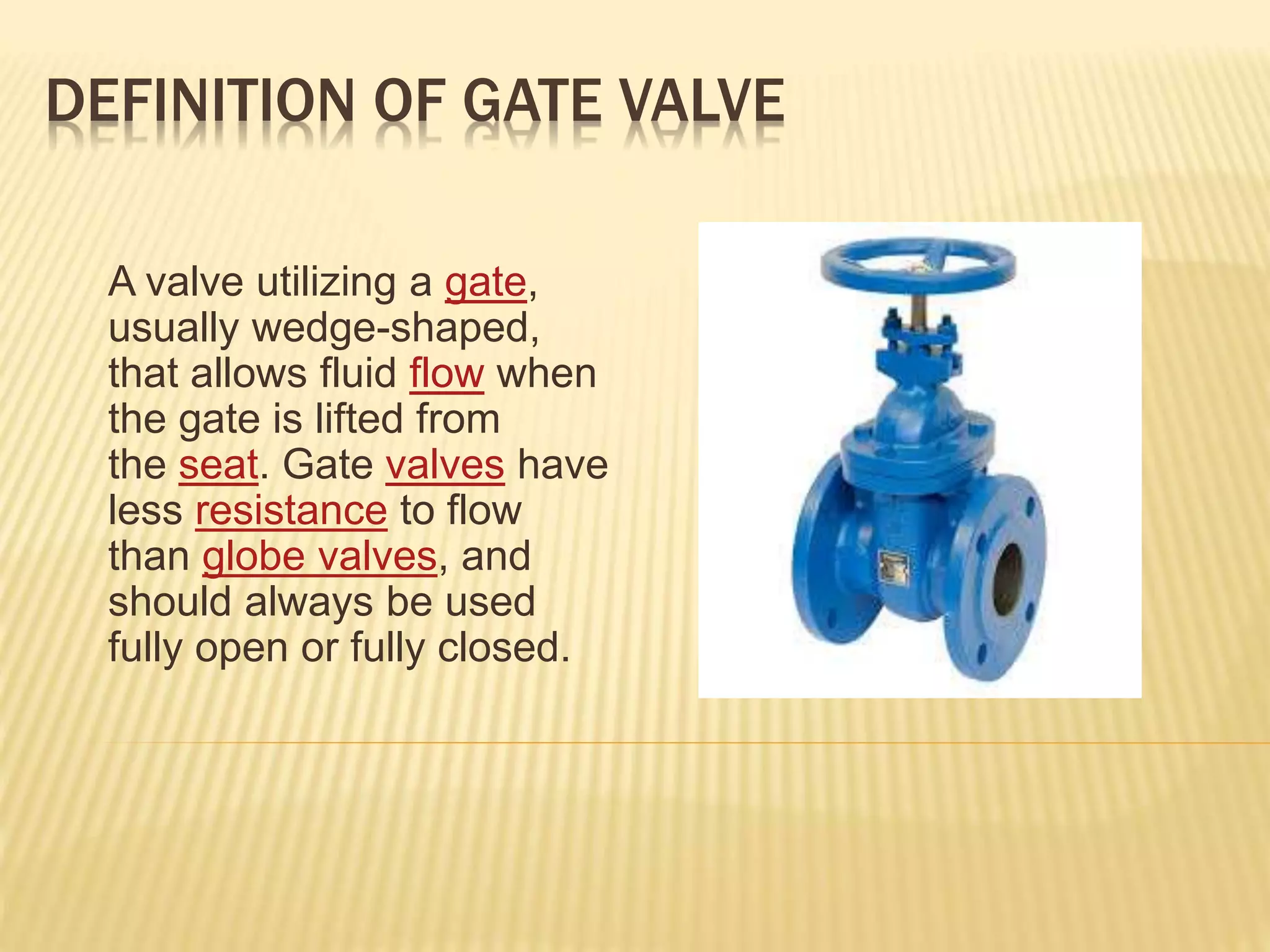

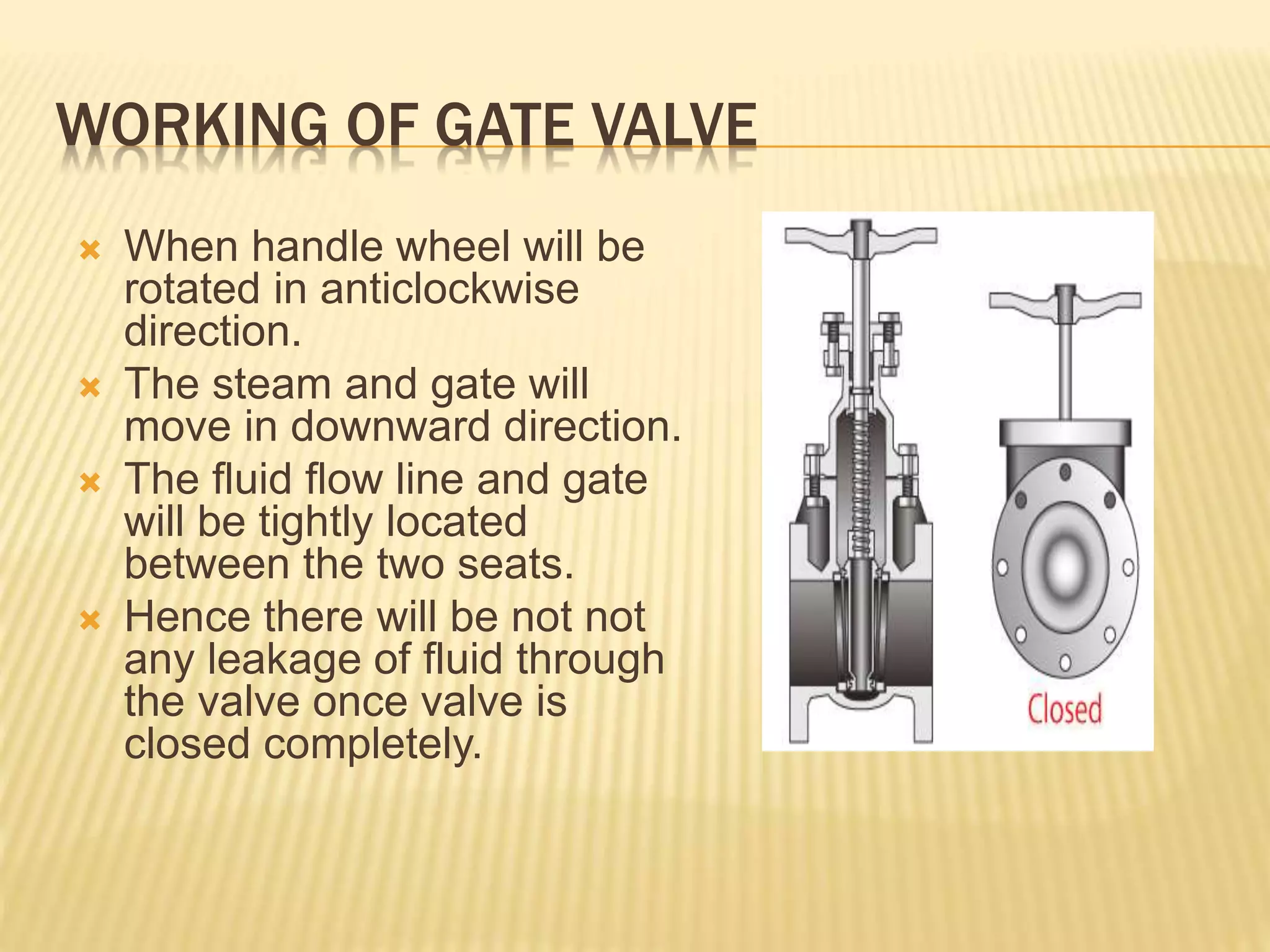

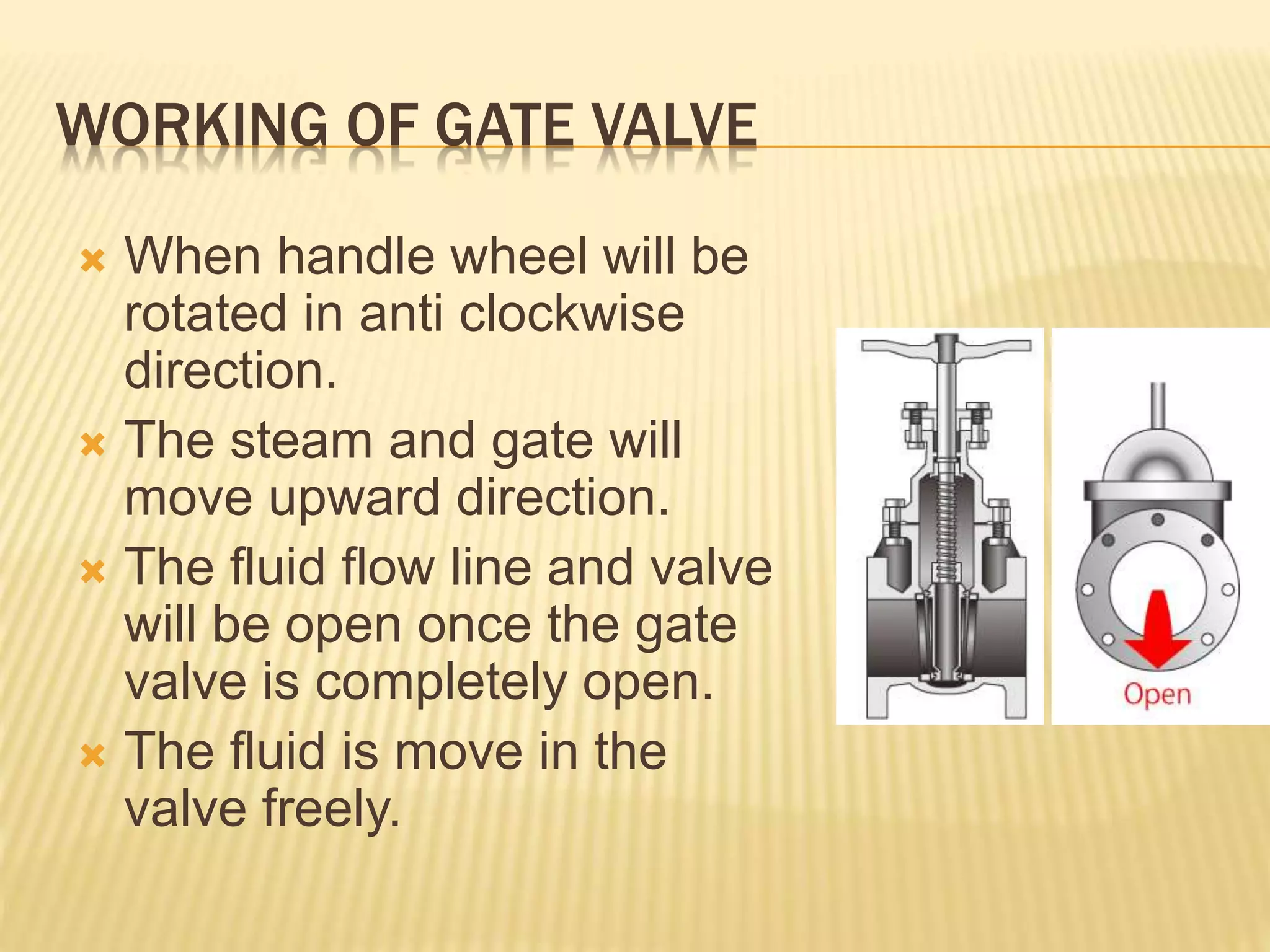

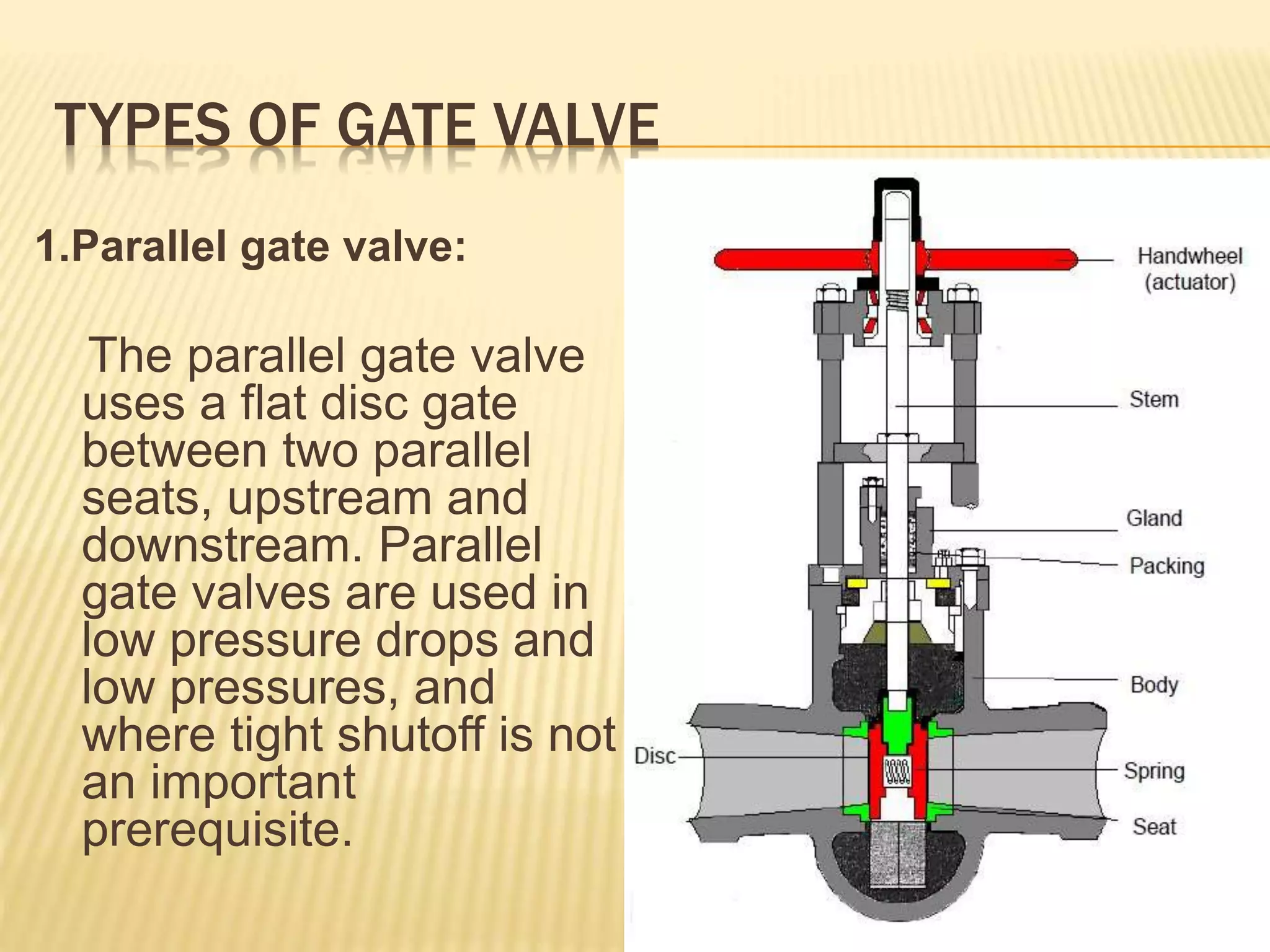

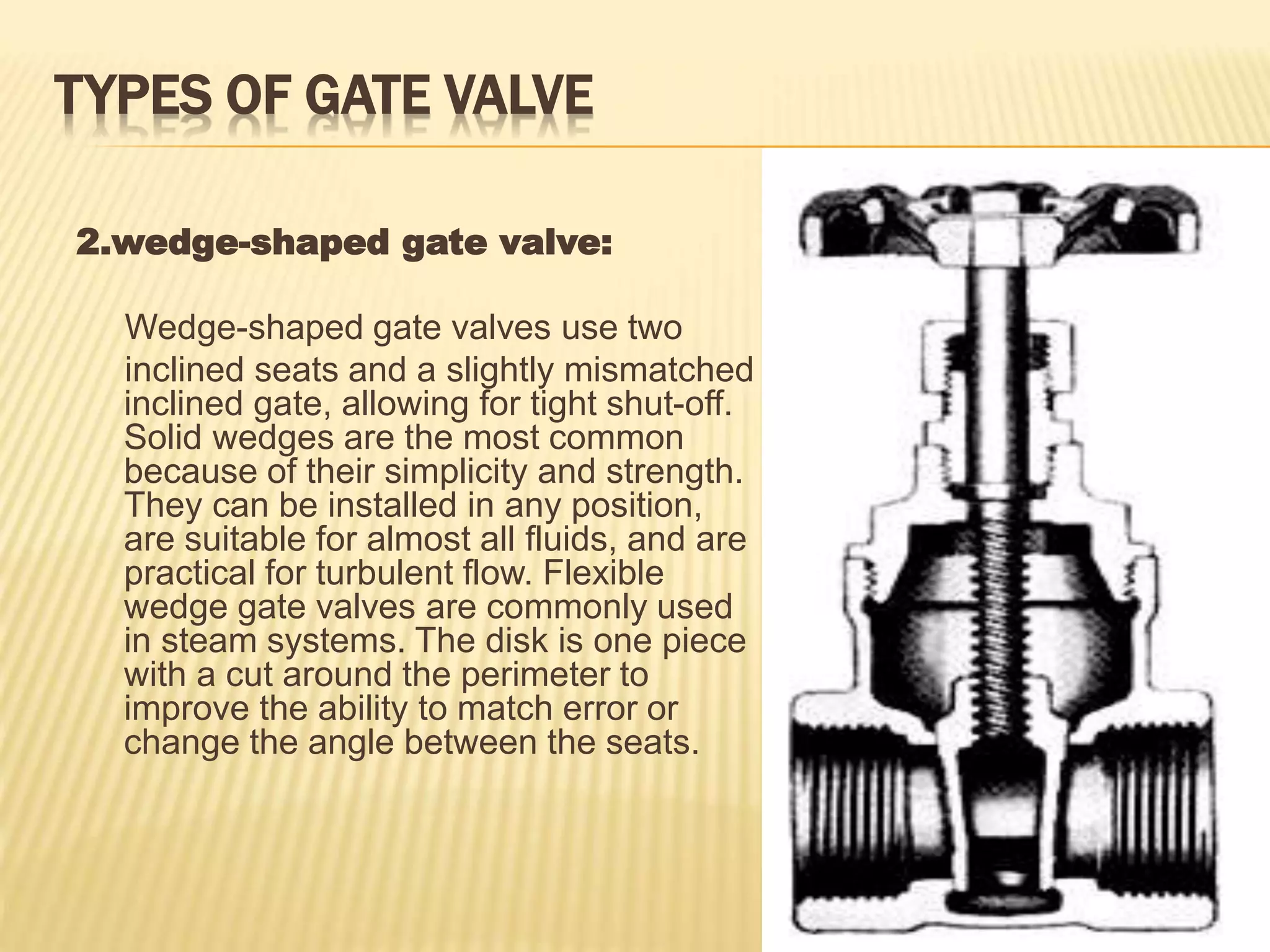

A gate valve uses a wedge-shaped gate that allows fluid flow when lifted off its seat. Gate valves have less resistance to flow than globe valves and should always be fully open or closed. There are two main types - parallel gate valves which use a flat disc between parallel seats for low pressures, and wedge-shaped valves which use inclined seats and gate for tight shut-off. Gate valves are commonly used in air, fuel gas, feedwater, steam, and other piping systems due to their good shut-off characteristics, bi-directionality, and minimal pressure loss through the valve. However, they are not quick opening/closing and require more space than other valves.