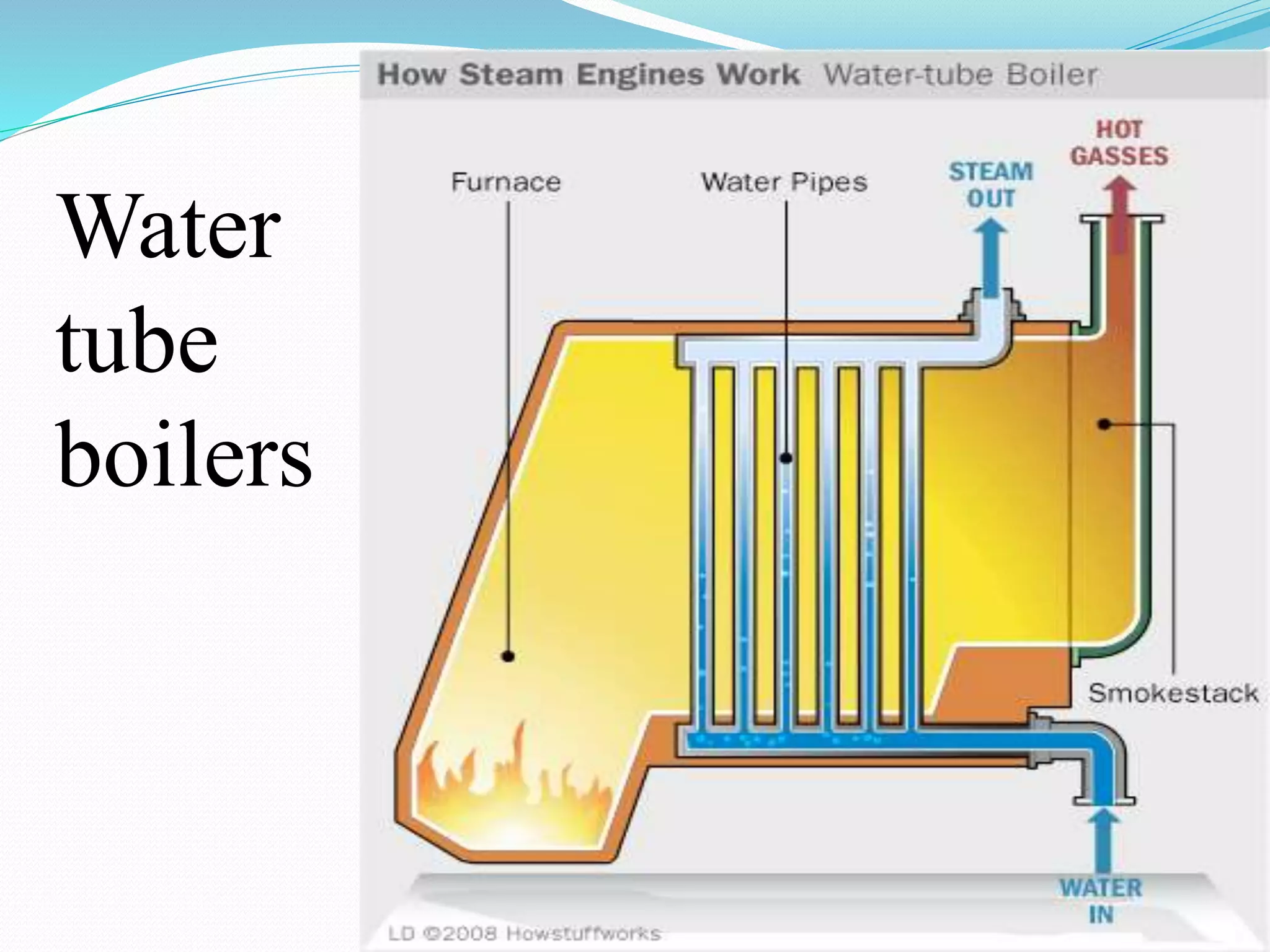

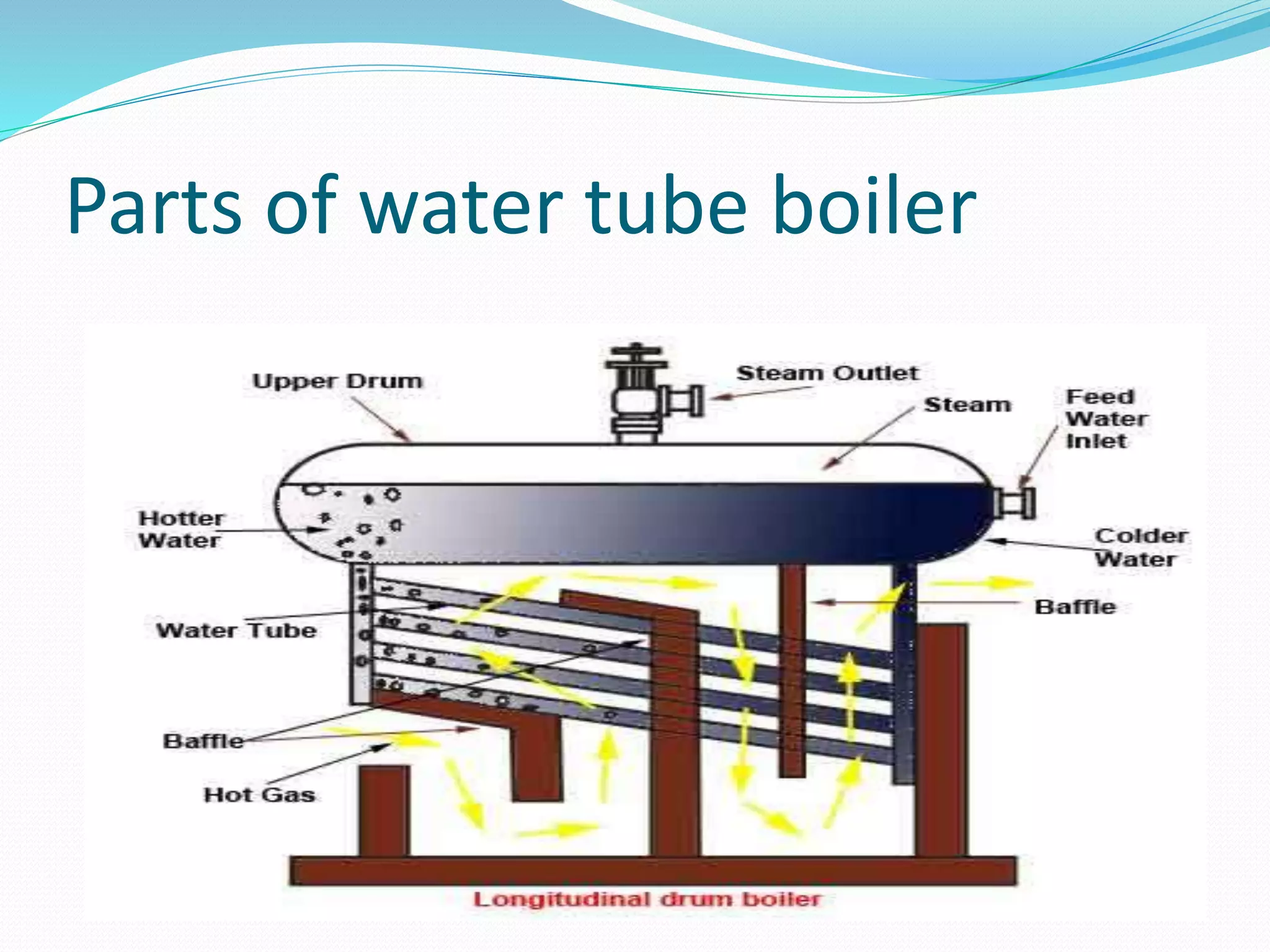

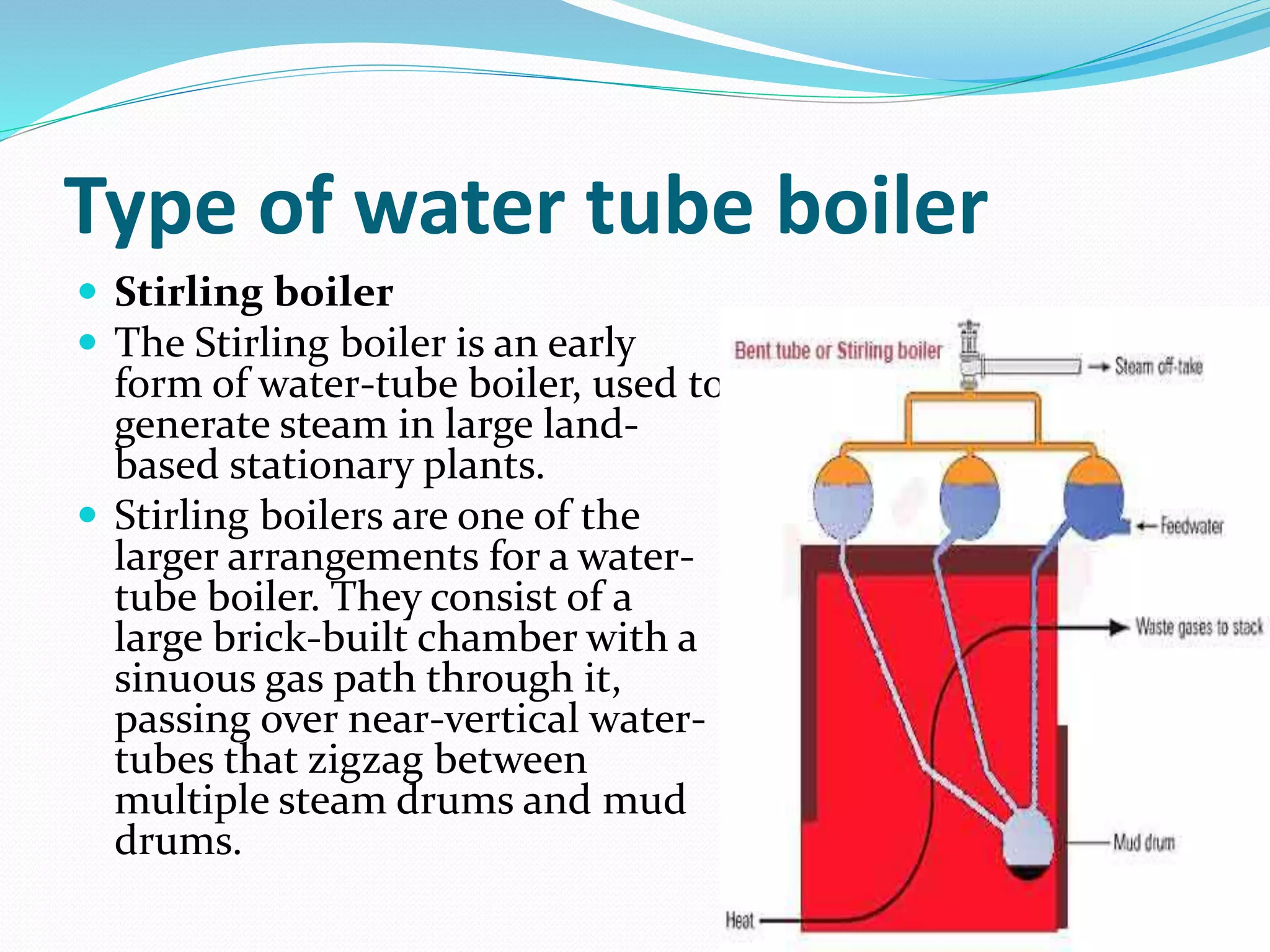

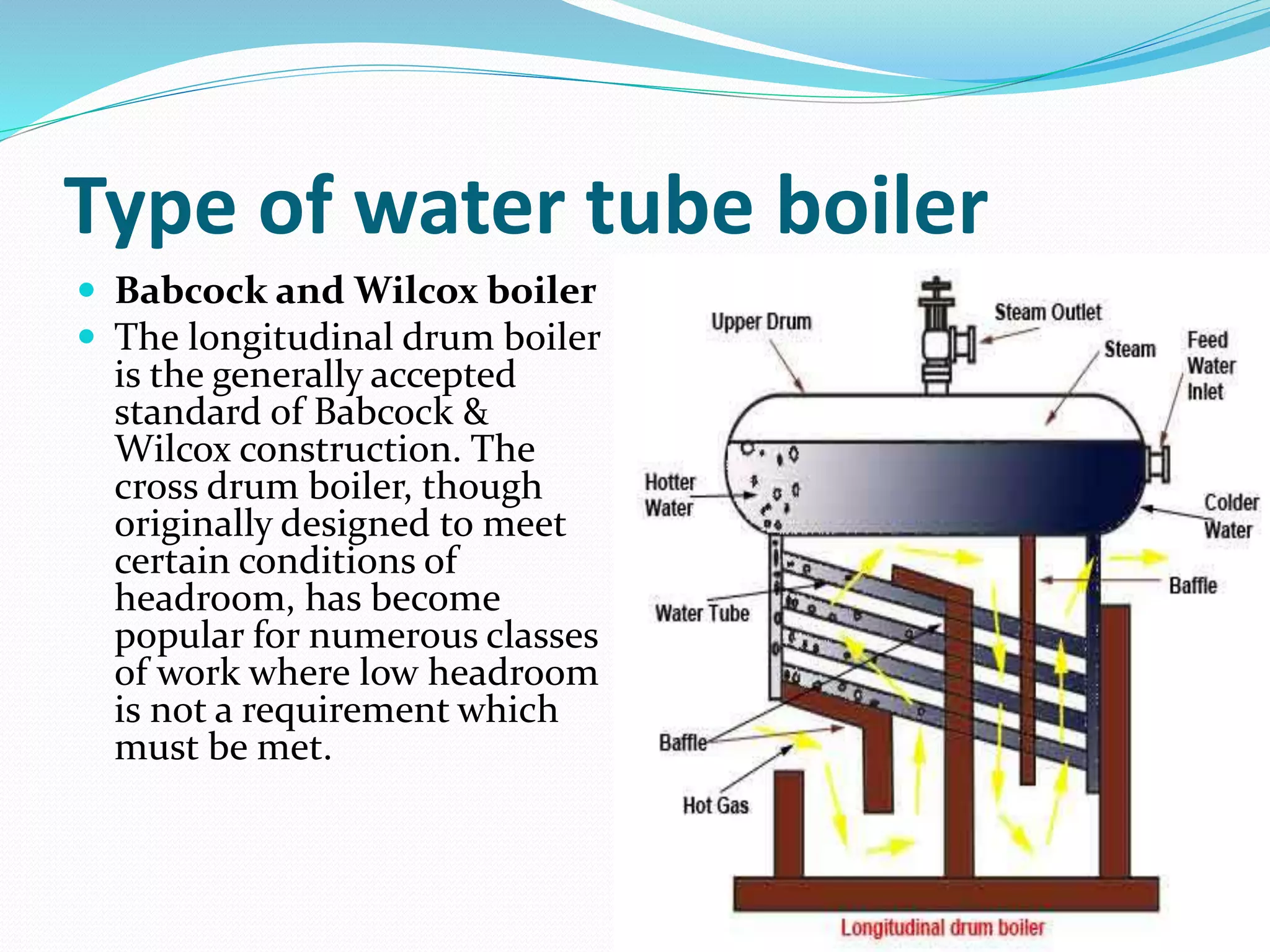

Water tube boilers have water flowing inside tubes and gases circulating outside. They are used for high steam demands and pressures between 4,000-120,000 kg/hour. Water tube boilers have higher efficiency and steam generation capacity than fire tube boilers due to their design with water inside tubes and gases outside providing better heat transfer. They require pure feed water and more maintenance than fire tube boilers.