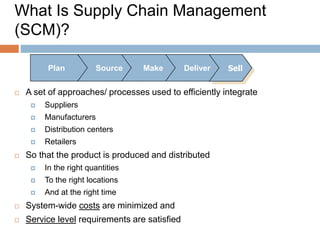

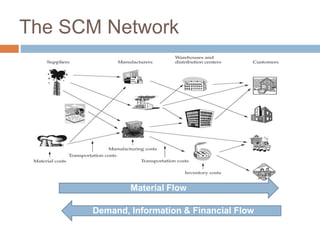

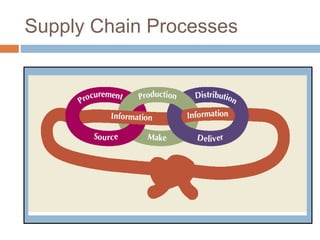

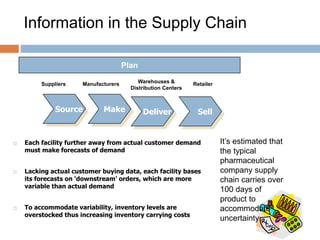

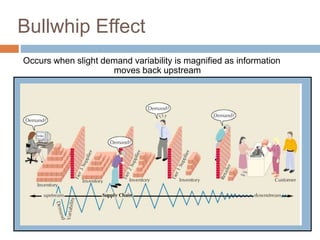

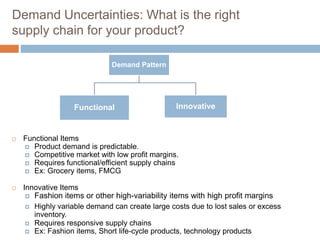

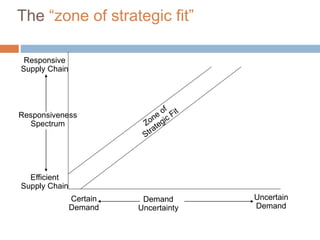

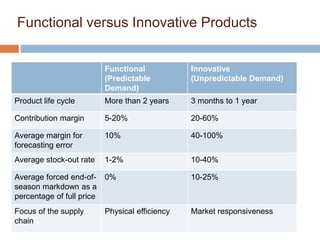

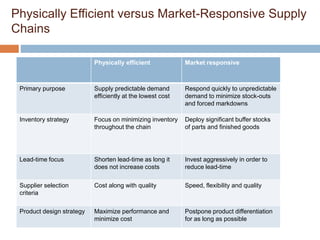

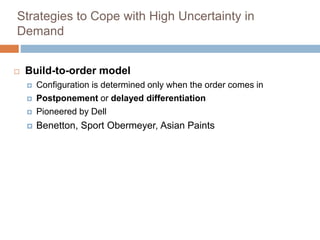

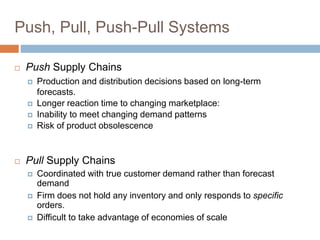

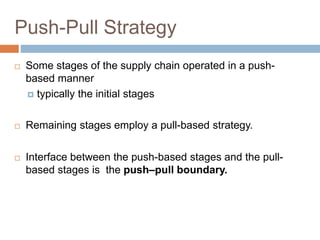

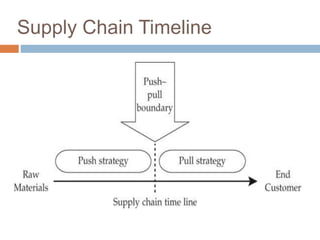

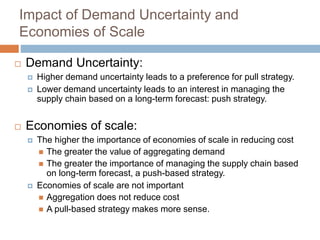

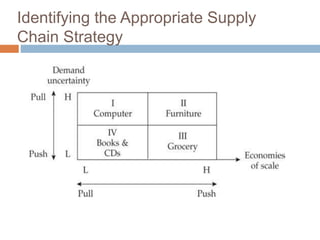

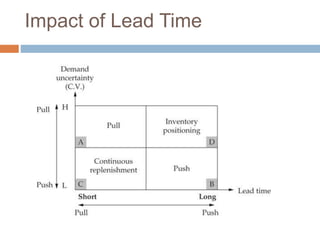

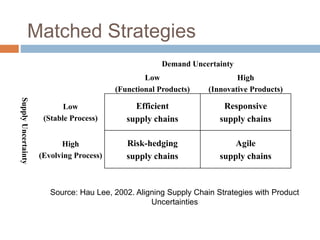

This document discusses supply chain management (SCM) and key aspects of effective SCM. It defines SCM as integrating suppliers, manufacturers, distributors and retailers to minimize costs and meet demand. It highlights the importance of SCM due to risks like demand uncertainty. It also discusses challenges like efficiency pressures and risks. Effective SCM requires strategies like collaboration, visibility, and responsiveness to disruptions. The document outlines SCM processes and how the bullwhip effect can occur when demand variability amplifies upstream. It provides strategies to reduce this effect and cope with uncertainty.