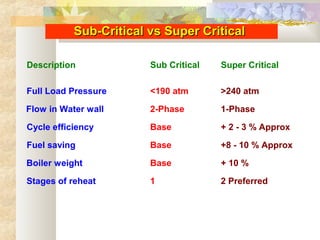

This document discusses supercritical power plants. It begins by defining critical condition as the state of a substance beyond which there is no clear distinction between the liquid and gaseous phases. It then defines a supercritical plant as one that operates above the critical condition, with water reaching this state at 374°C and 22.1 MPa pressure.

The document explains that supercritical plants have higher efficiency than subcritical plants, operating at temperatures over 580°C and pressures over 23 MPa, yielding efficiencies as high as 46%. This is more efficient than subcritical plants which operate at 455°C and efficiencies around 40%. Supercritical plants also reduce emissions by burning less coal per kWh produced.

![Coal-fired Supercritical Power plants operate at

very high temperature [580°C temp.] & with a

pressure of 23 MPa)

Resulting much higher heat efficiencies (46%),

as compare to Sub-Critical coal-fired plants.

Sub-Critical coal-fired plant operates at 455°C

temp., and efficiency of within 40%.](https://image.slidesharecdn.com/gggfgganeshpptsonthermalpowerplant-131009013759-phpapp02/85/ganesh-ppts-on-supercritical-thenology-13-320.jpg)