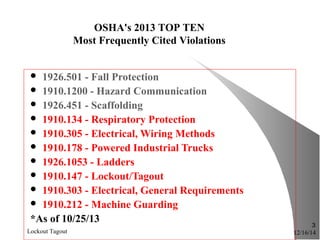

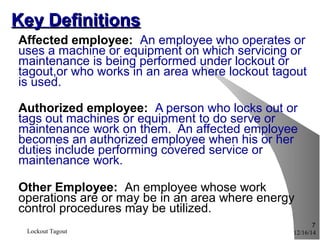

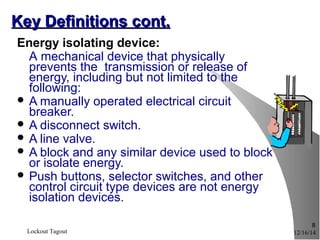

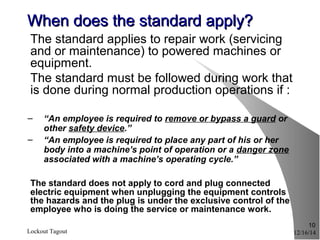

The document discusses OSHA's top 10 most frequently cited standards for fiscal year 2013. Lockout/tagout was the 8th most cited standard. It then provides an overview of lockout/tagout requirements including key definitions, when the standard applies, required energy control programs and procedures, the six steps for applying and releasing lockout/tagout, and maintaining lockout/tagout during shifts or personnel changes. It concludes with an OSHA case study example.