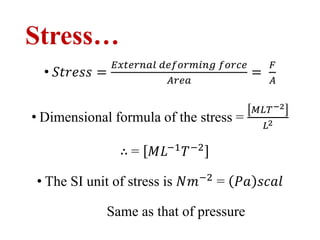

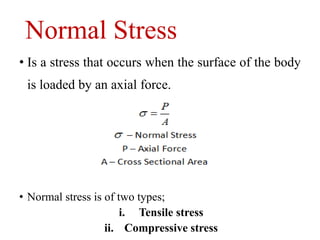

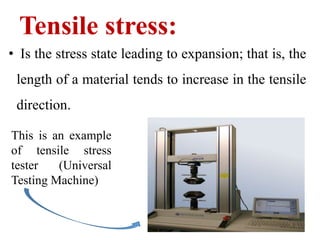

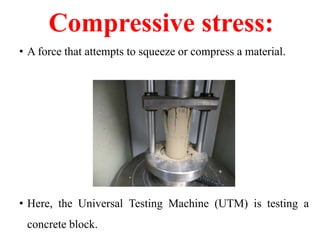

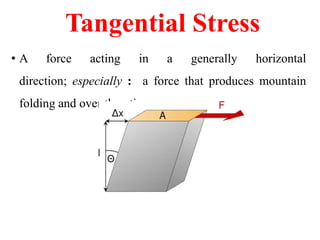

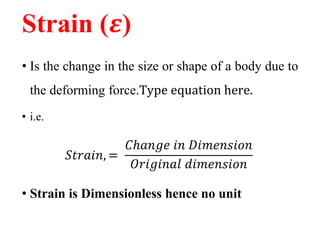

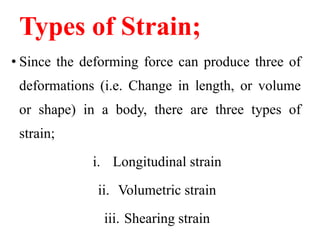

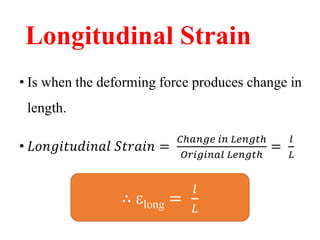

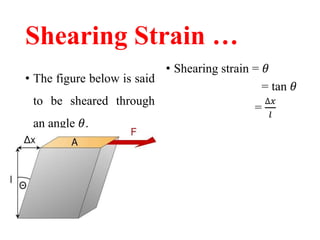

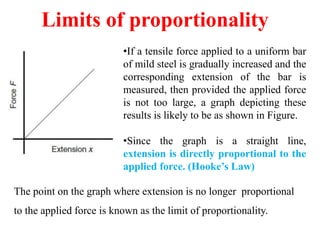

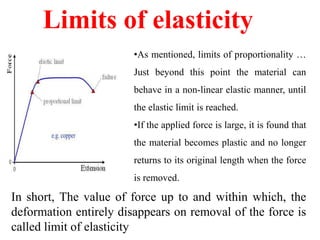

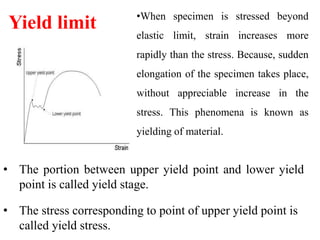

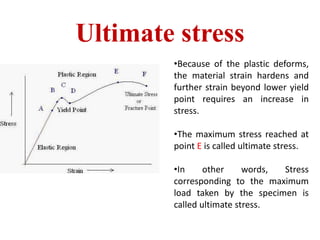

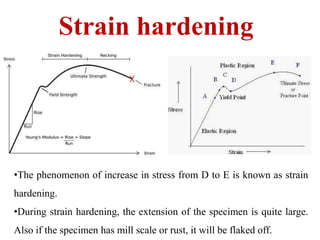

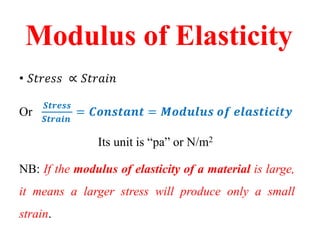

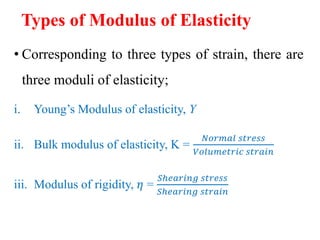

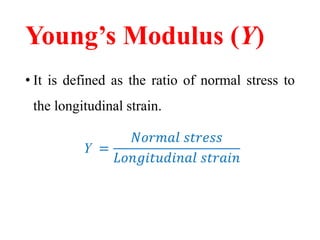

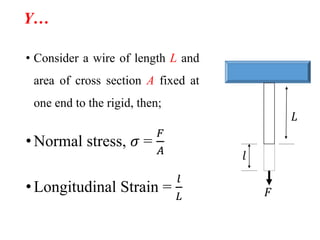

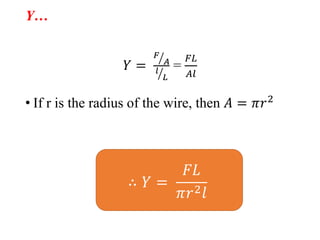

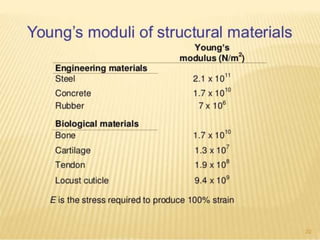

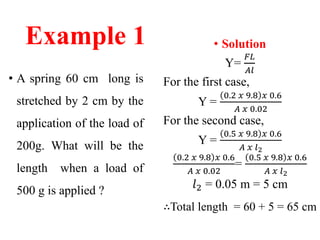

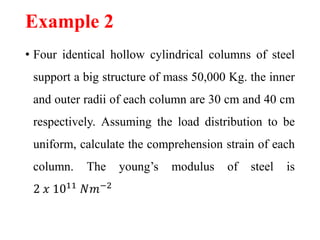

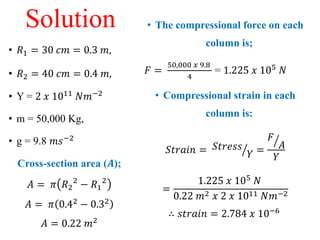

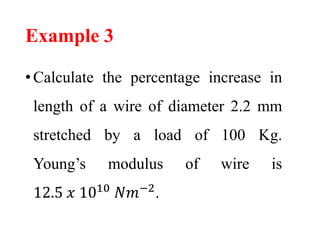

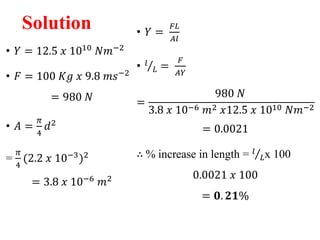

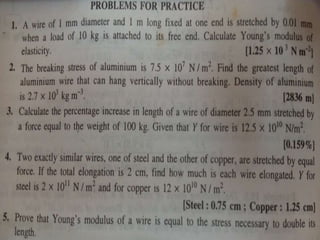

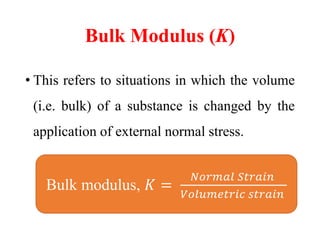

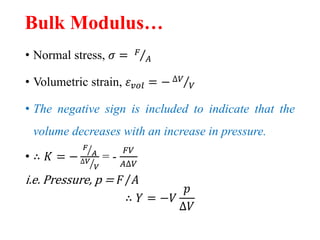

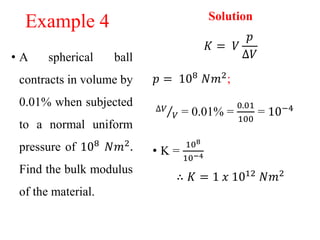

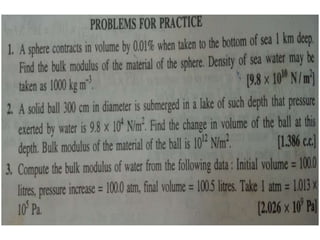

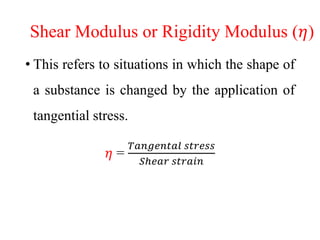

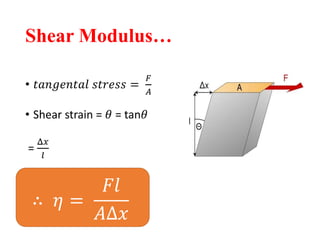

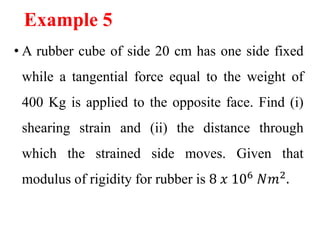

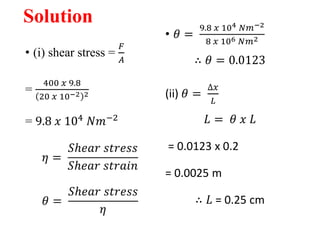

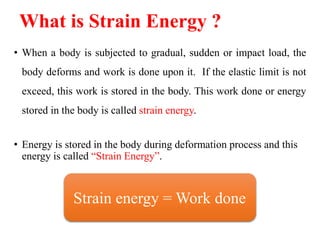

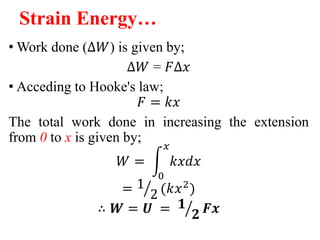

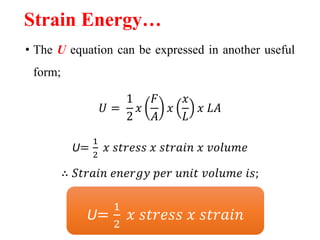

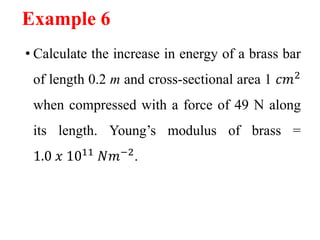

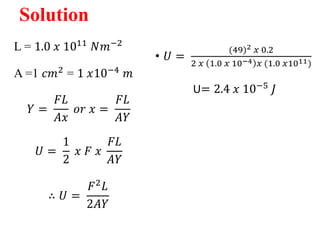

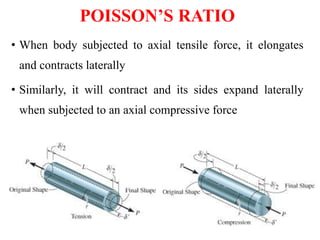

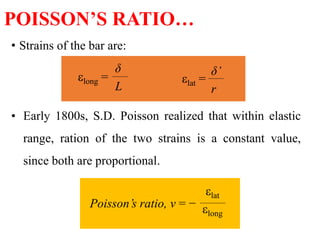

The document discusses the principles of strength of materials, including definitions and properties of rigid and deformable bodies, stress and strain, as well as various types of stress and their applications in structural analysis. It also covers elasticity, different modulus types, and phenomena such as yielding, strain hardening, and Poisson's ratio, along with practical examples and calculations related to these concepts. Overall, it serves as a comprehensive overview of material strength and its implications in engineering.