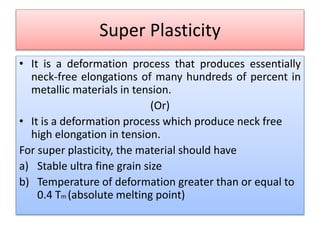

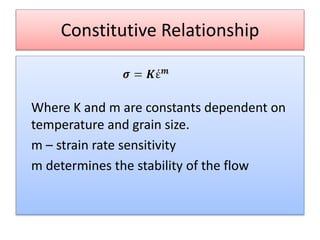

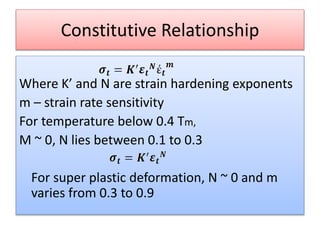

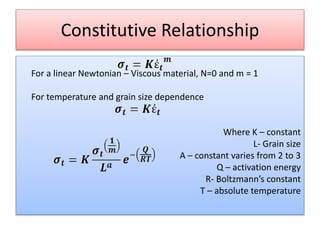

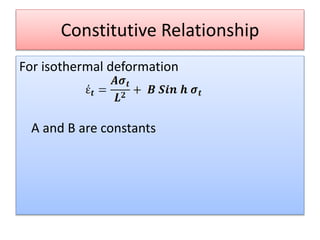

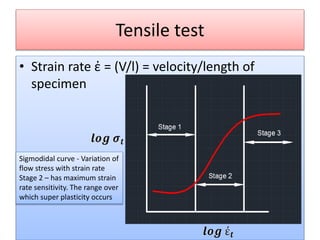

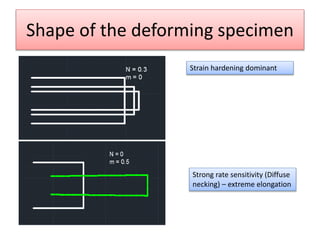

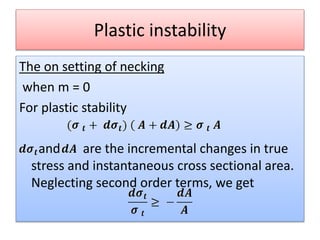

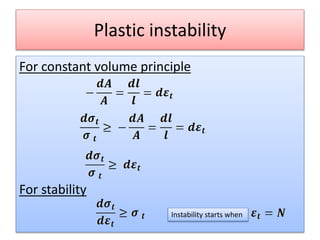

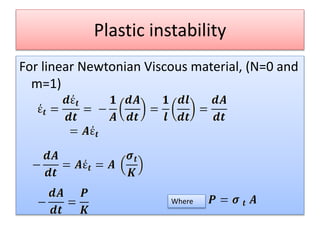

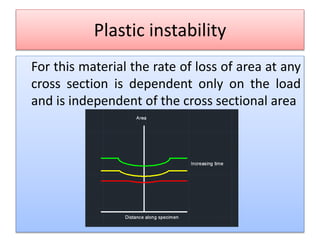

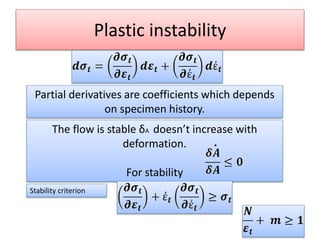

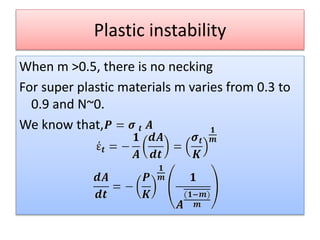

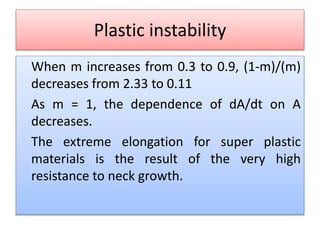

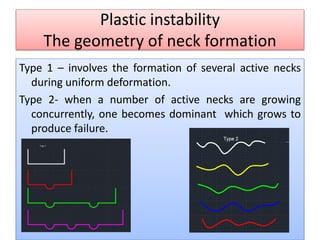

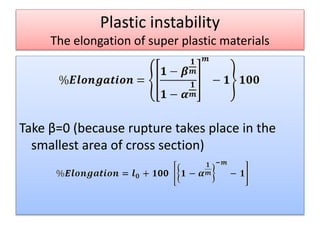

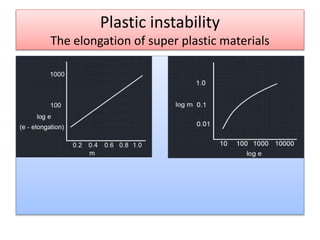

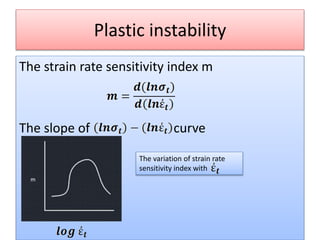

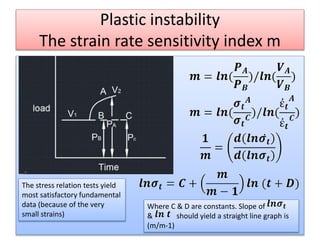

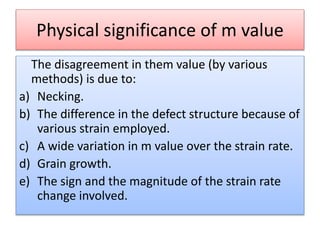

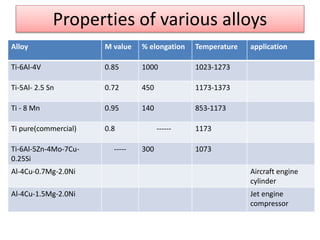

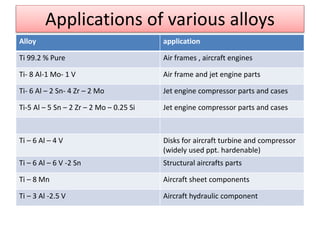

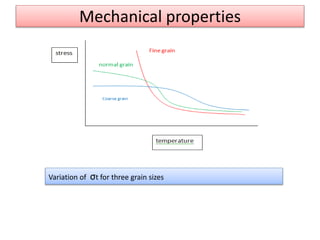

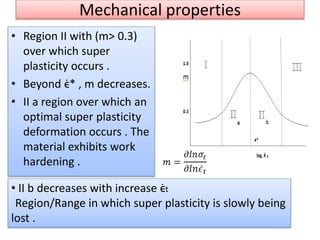

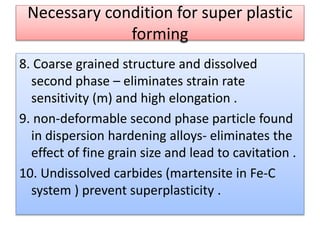

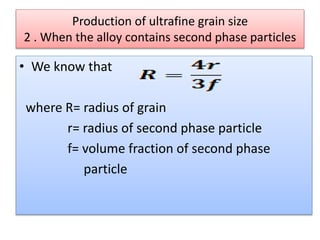

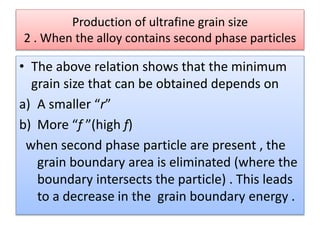

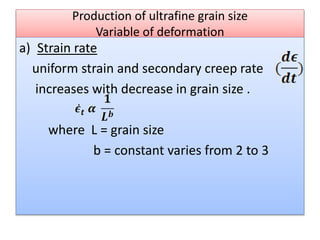

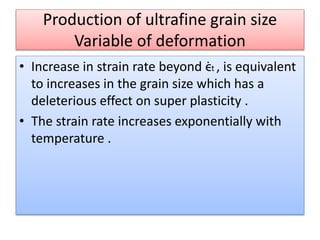

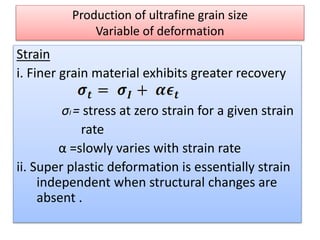

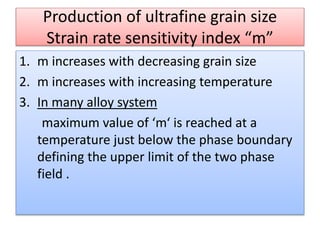

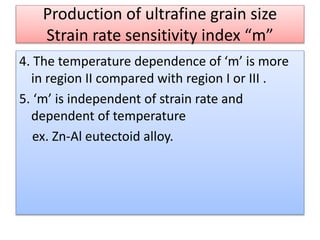

This document discusses super plasticity, which is a deformation process that produces high elongations in metallic materials during tension testing. For super plasticity to occur, the material must have an ultra fine grain size and be deformed at a temperature greater than or equal to 0.4 times the absolute melting point. The document outlines various constitutive relationships that describe super plastic deformation and discusses factors that influence strain rate sensitivity. It also examines conditions necessary for super plastic forming and methods for producing ultrafine grain sizes in materials.