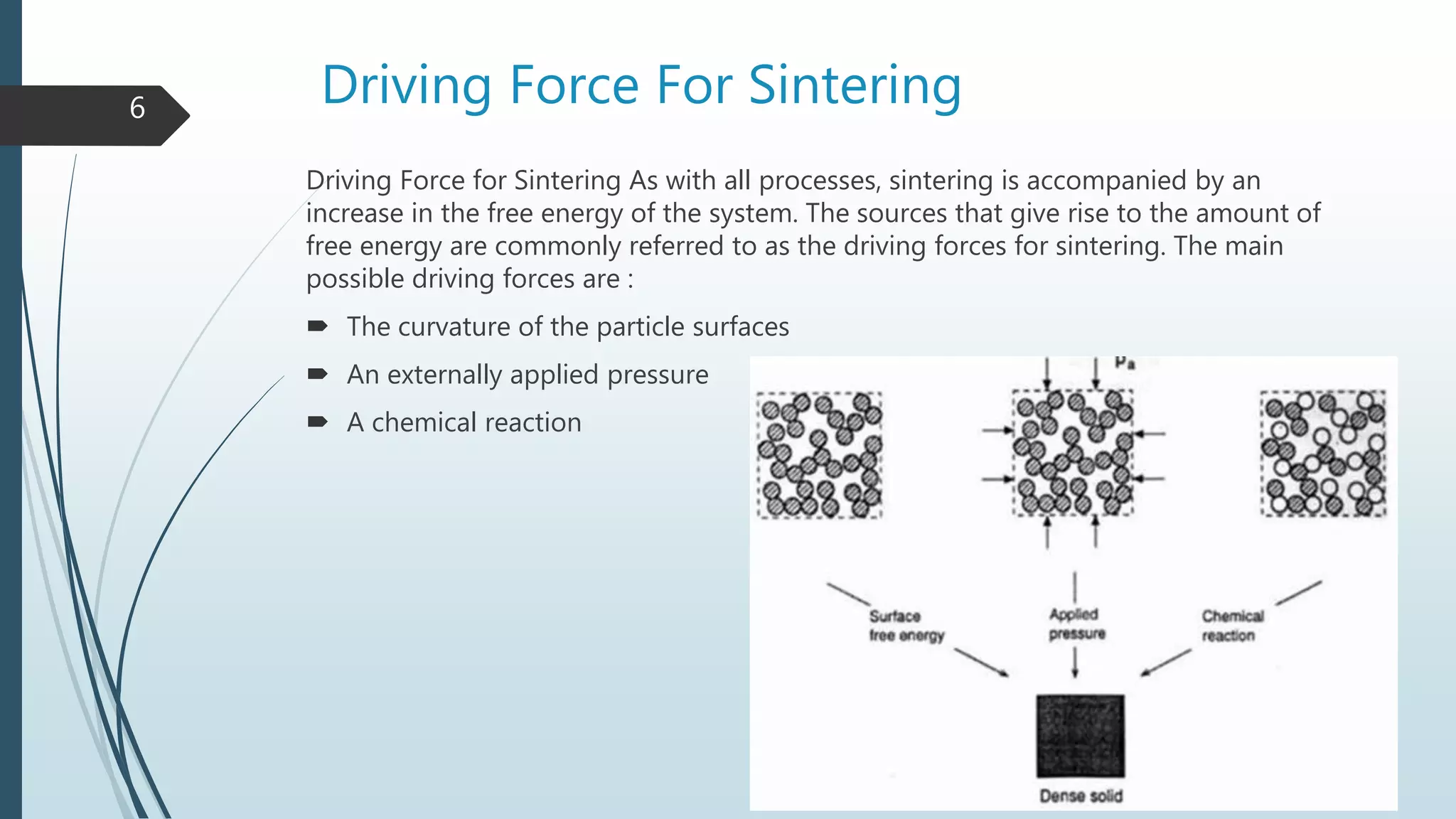

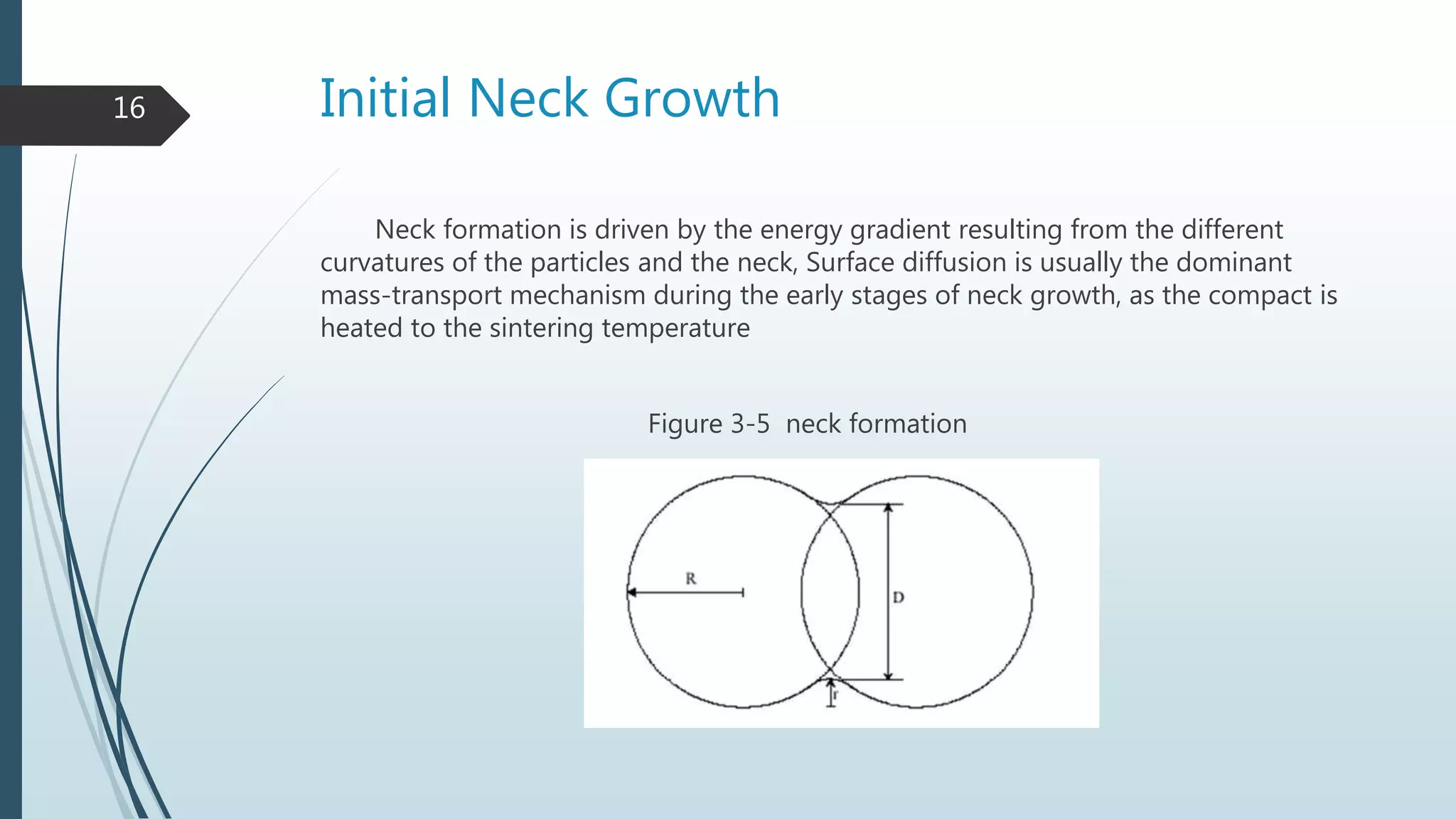

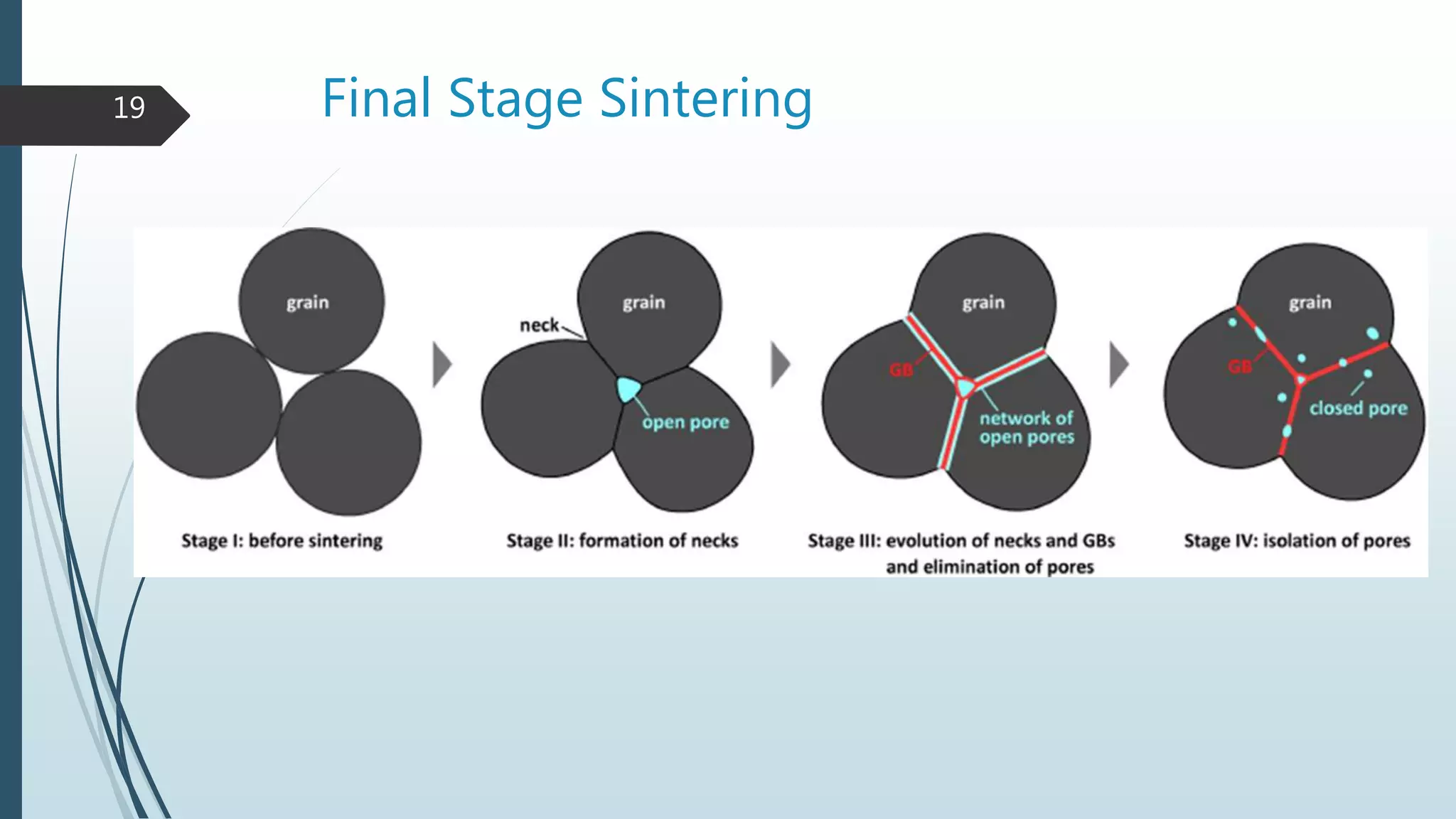

The document discusses the process of sintering, which involves heating powdered materials below their melting point to bond particles together through atomic diffusion. Sintering reduces porosity and improves material properties. It explains the stages of sintering - initial neck growth, intermediate pore channel closure, and final pore shrinkage. Different sintering mechanisms are described, including surface, grain boundary, and lattice diffusion. Solid-state, liquid-phase, and reactive sintering types are also summarized. Key sintering parameters and the advantages and disadvantages of the process are presented.