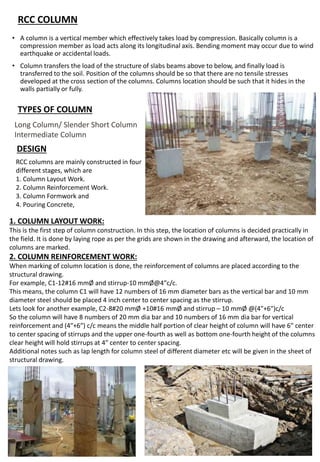

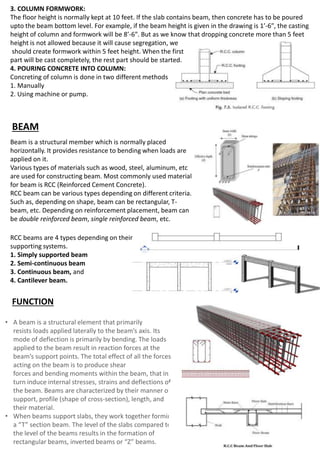

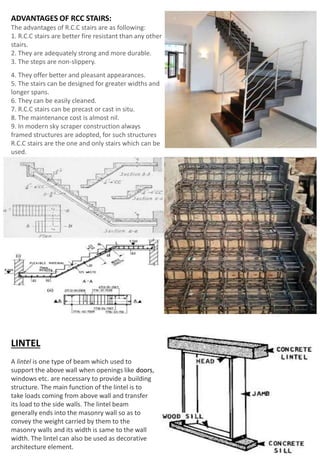

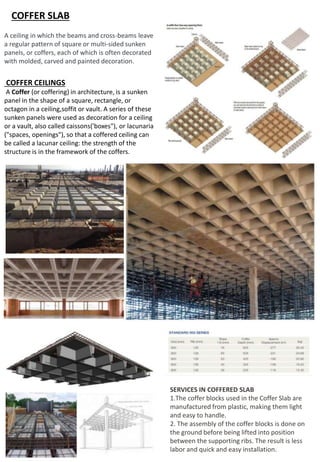

The document provides a detailed explanation of various RCC (Reinforced Cement Concrete) structural elements including columns, beams, slabs, stairs, lintels, chajjas, canopies, coffer slabs, and pergolas, along with their purposes, design considerations, and construction processes. It covers how these elements interact in building construction and highlights their various types, materials, and advantages. Overall, the document serves as an informative guide for architectural design and construction practices related to RCC structures.