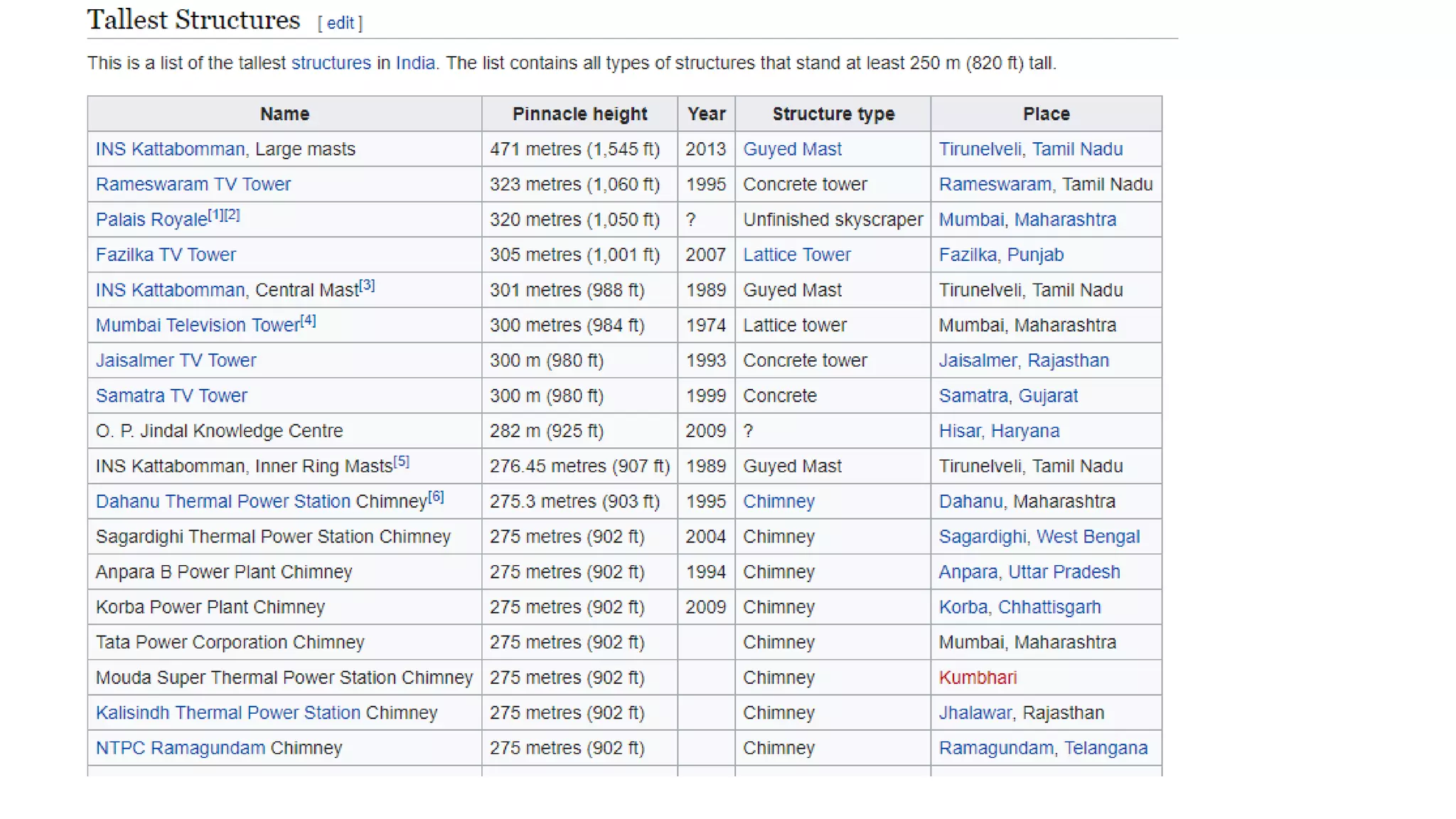

Steel structures have high strength-to-weight ratios and enable long column-free spans, making them popular for offices, multifamily housing, and industrial buildings. However, steel is more expensive and requires skilled labor and maintenance. Reinforced concrete (RCC) structures are less flexible than steel but offer advantages like low floor-to-floor heights, fire resistance without additional protection, and minimal maintenance needs. The choice between steel and RCC depends on the building type, location, budget, and schedule. Steel is well-suited for high-rises and temporary structures while RCC is commonly used in buildings, bridges, dams, tanks, and coastal infrastructure.