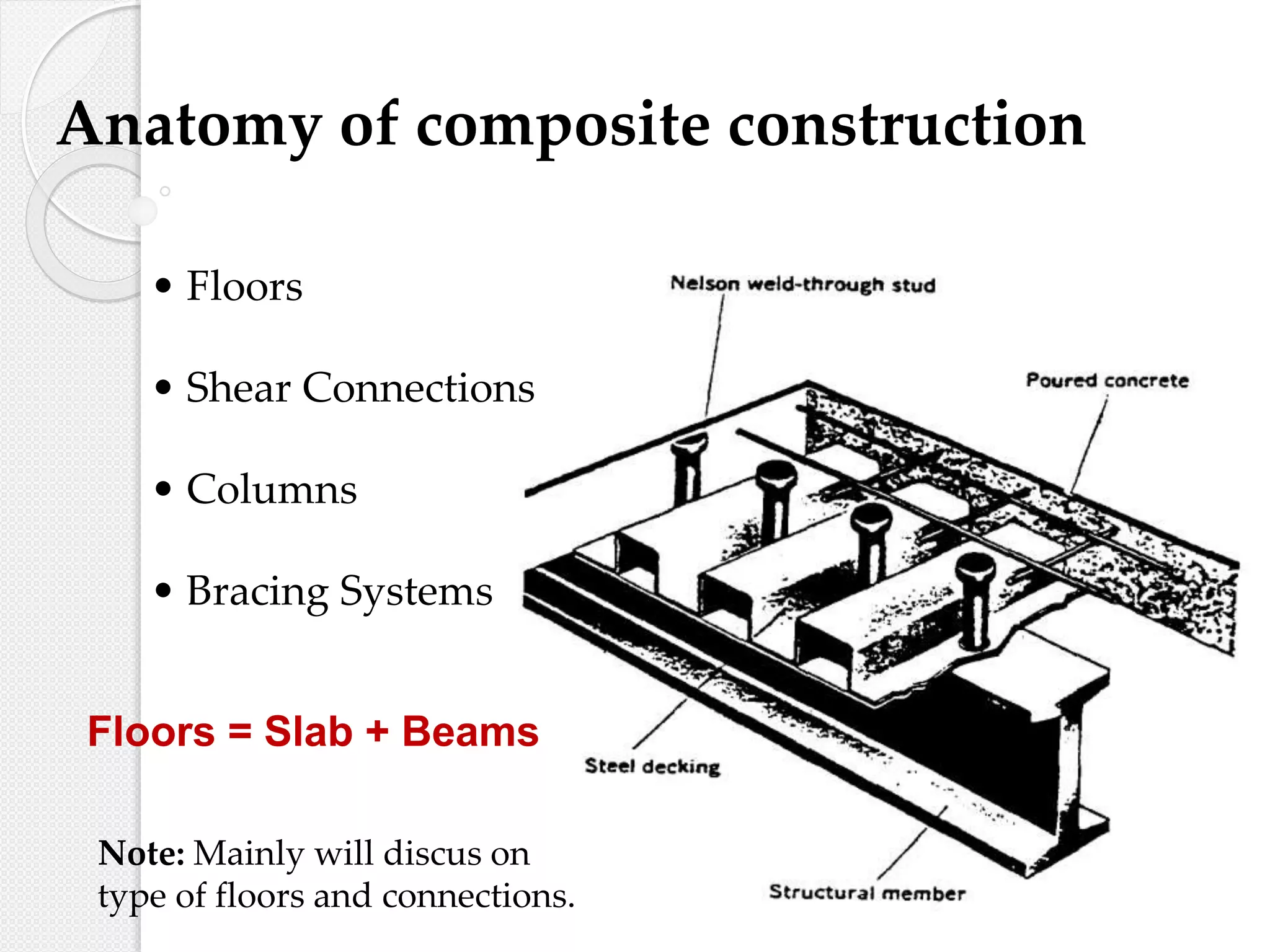

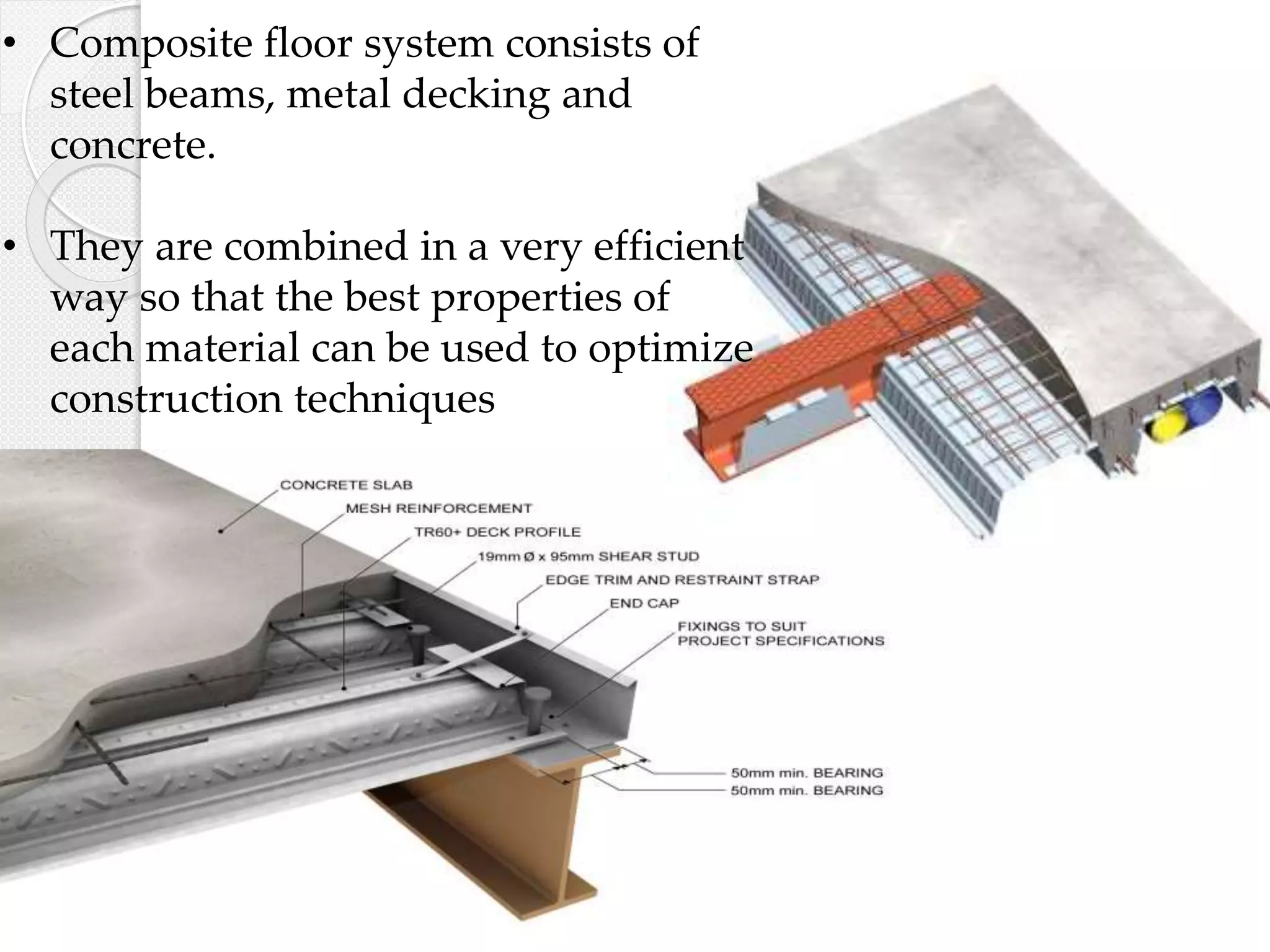

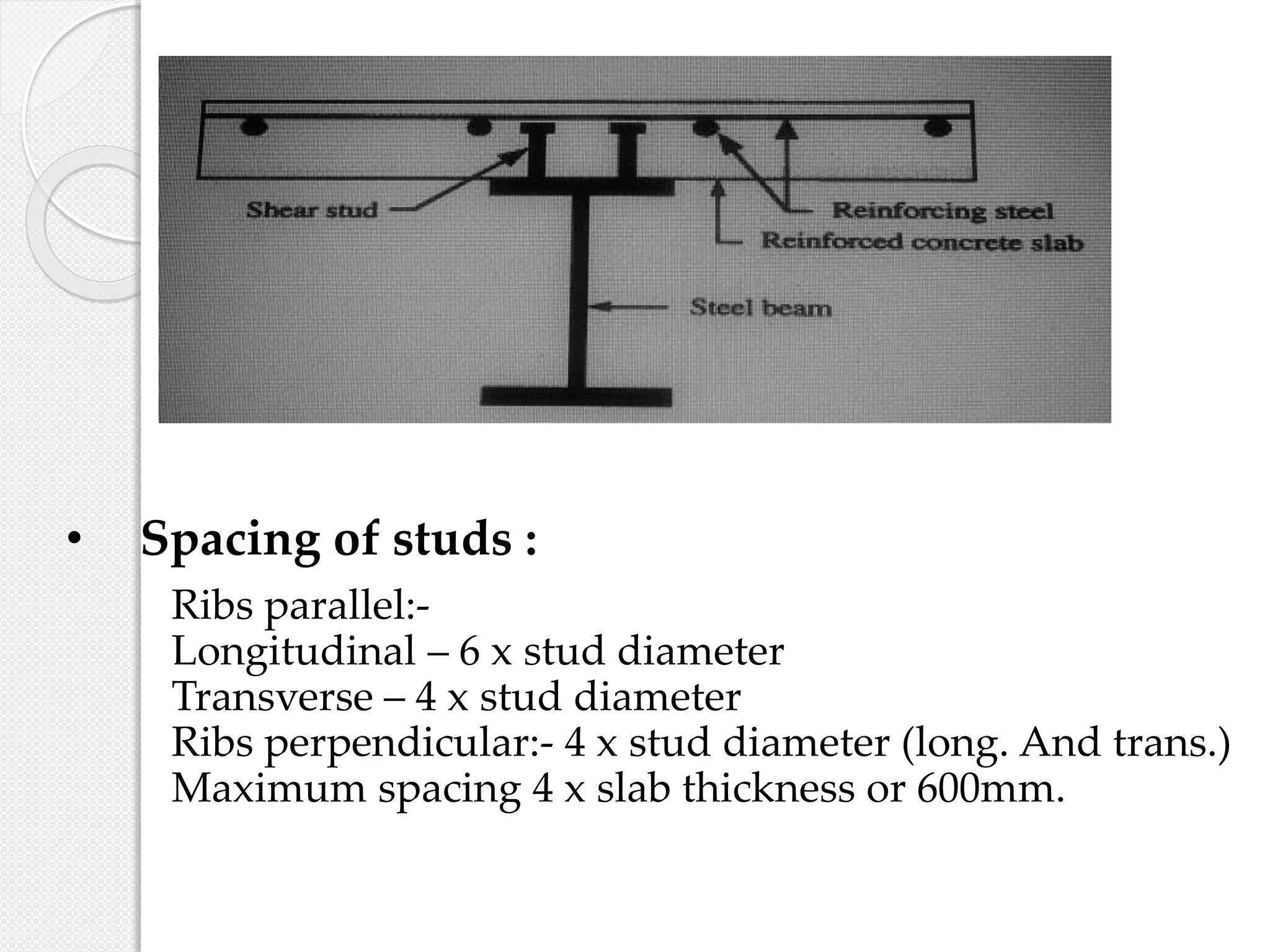

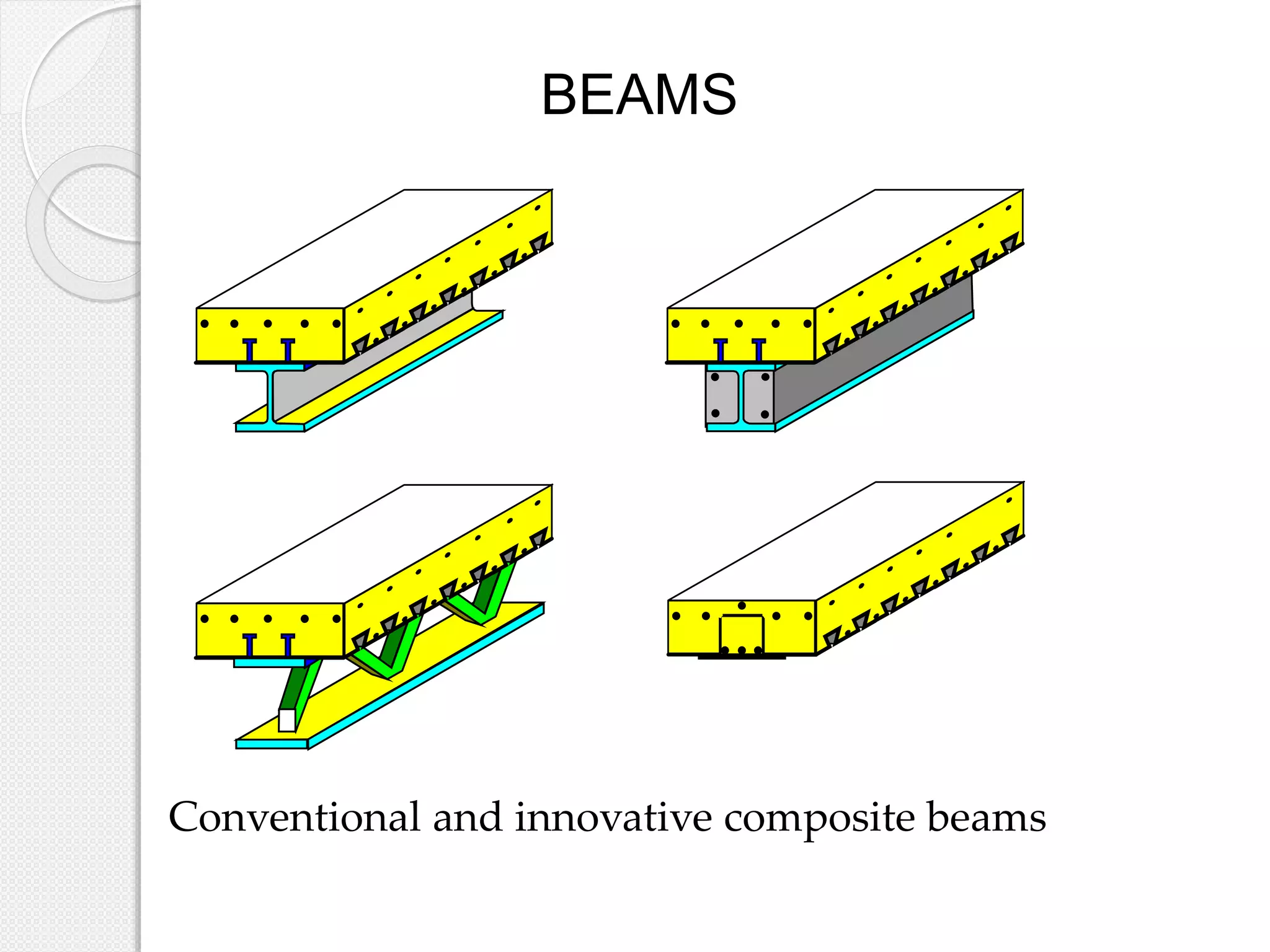

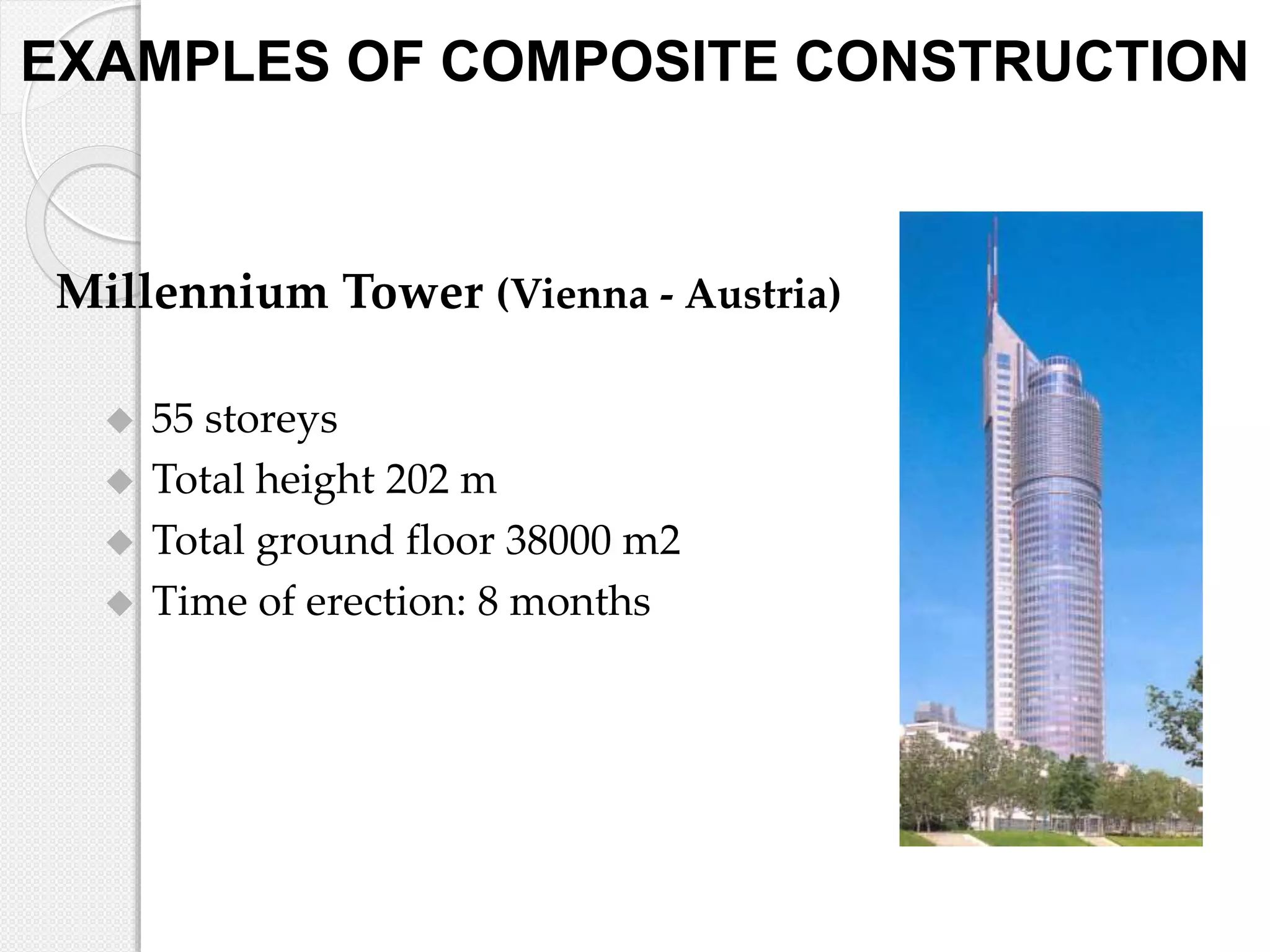

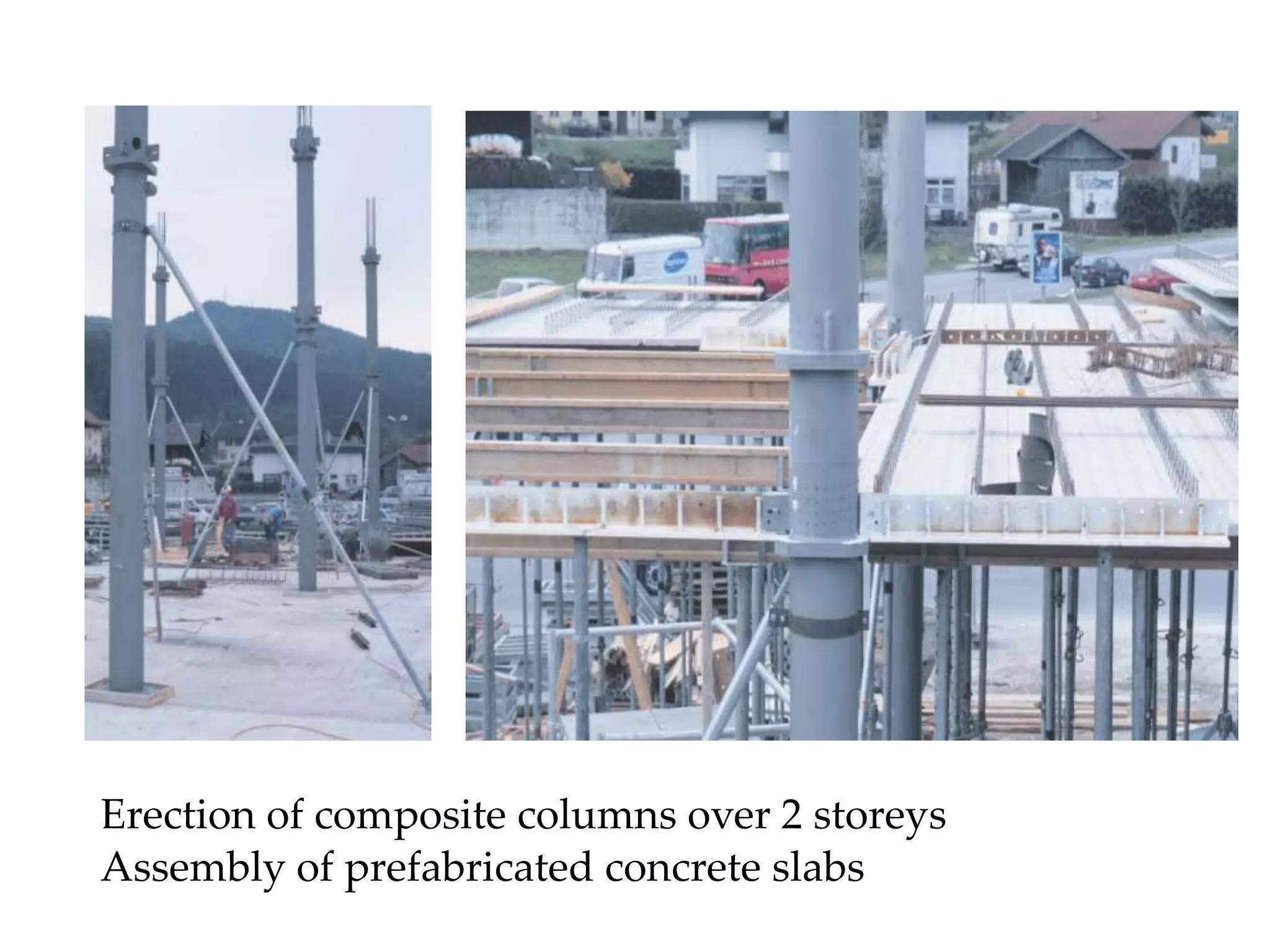

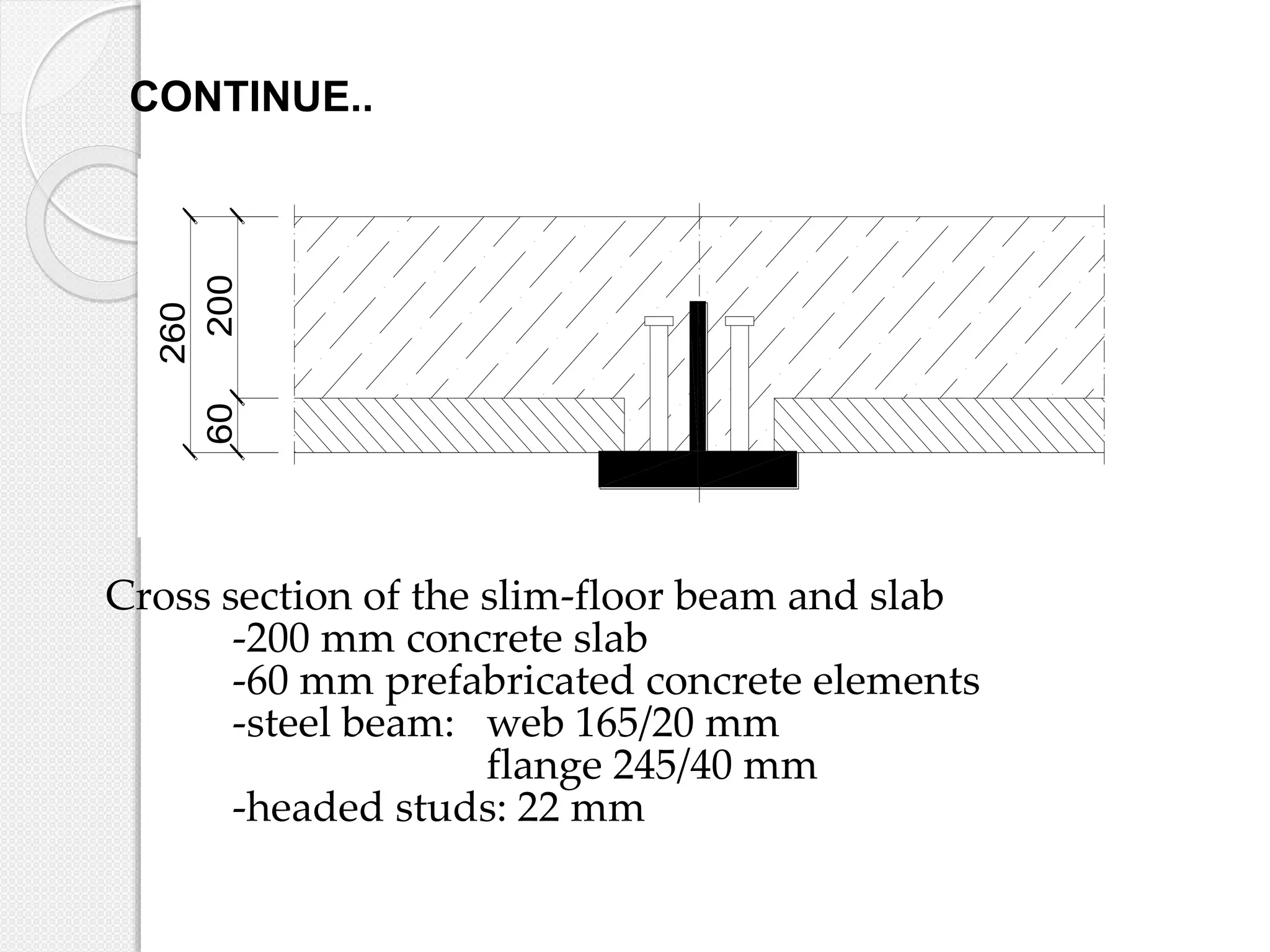

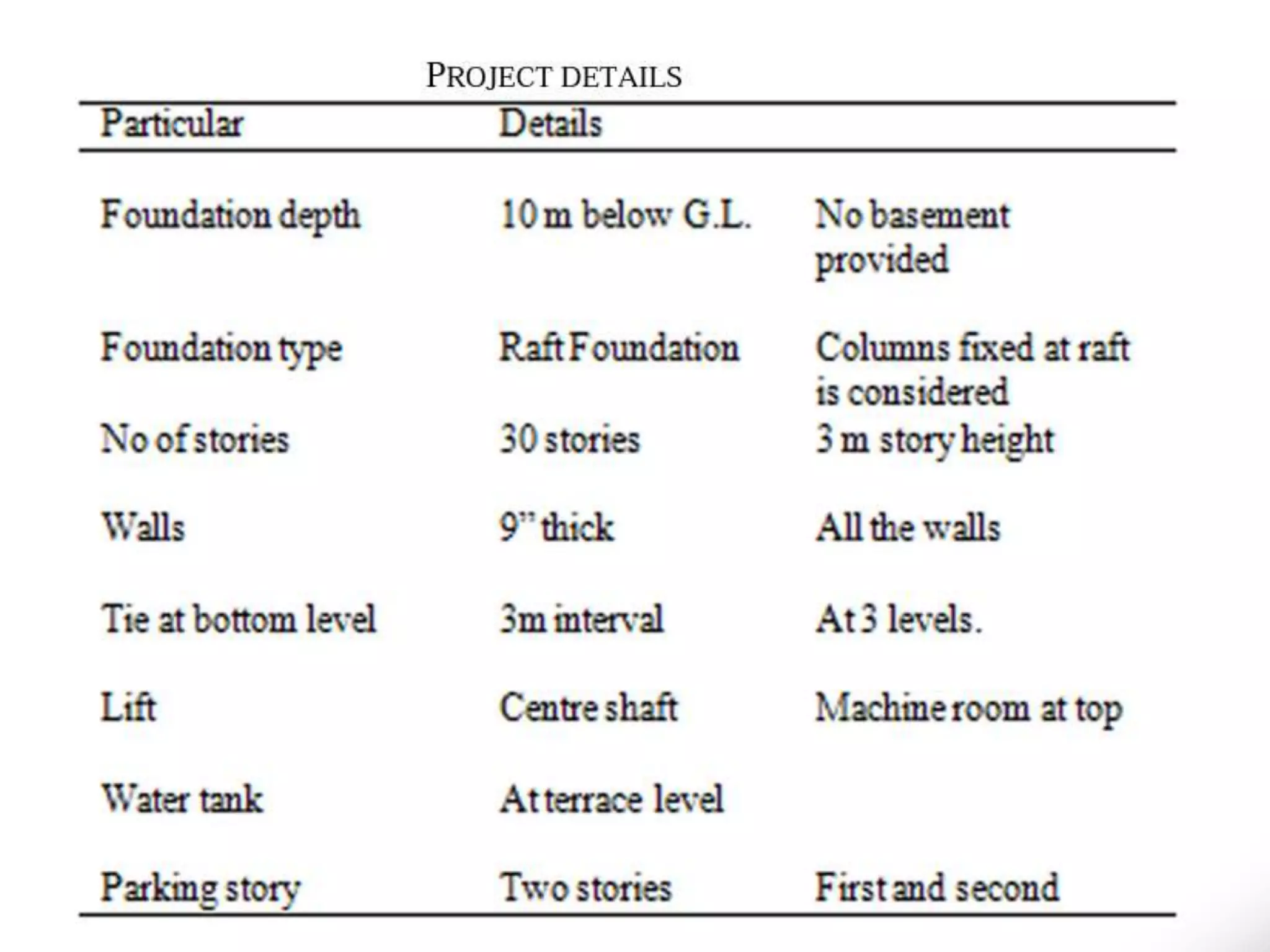

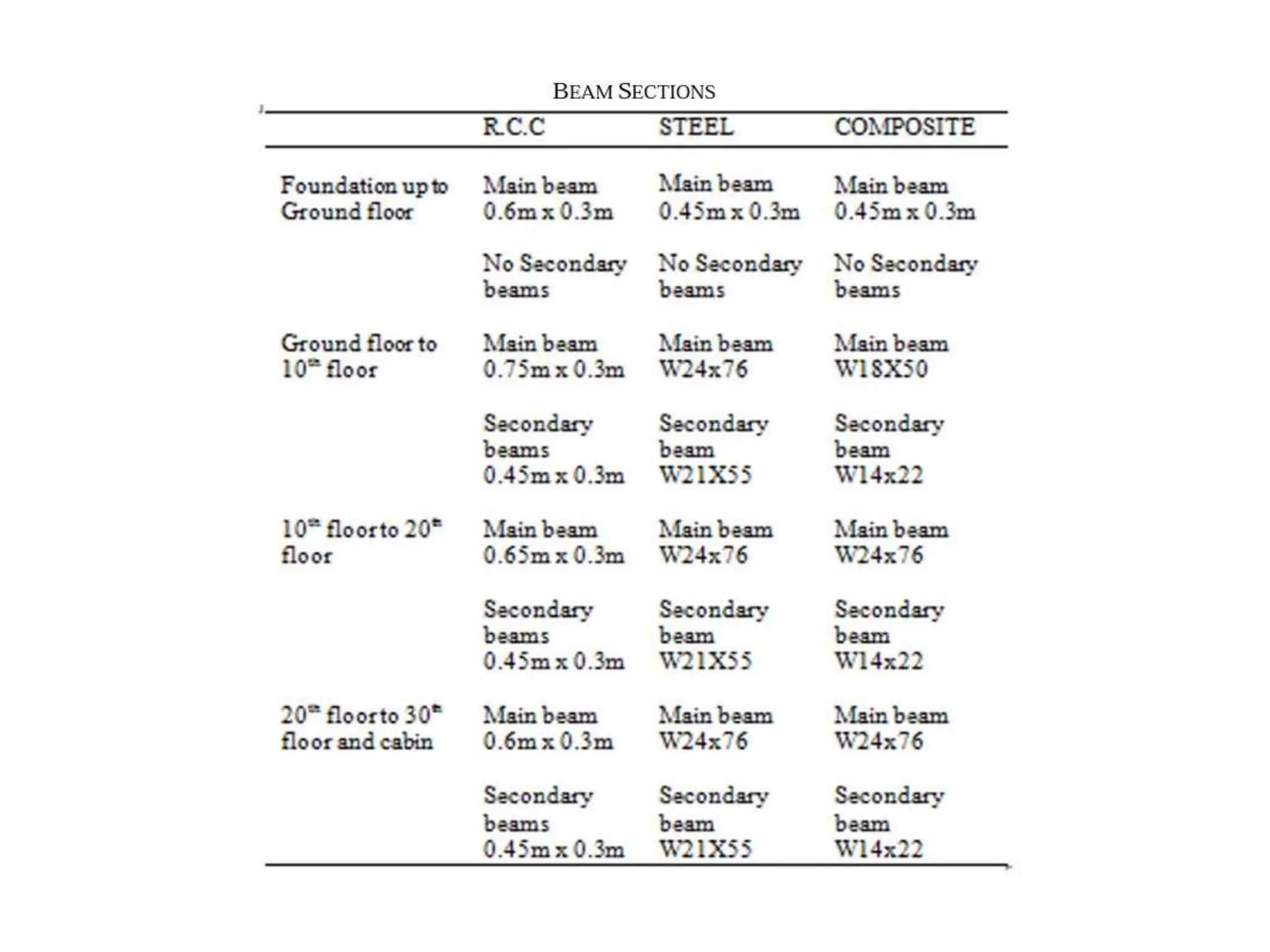

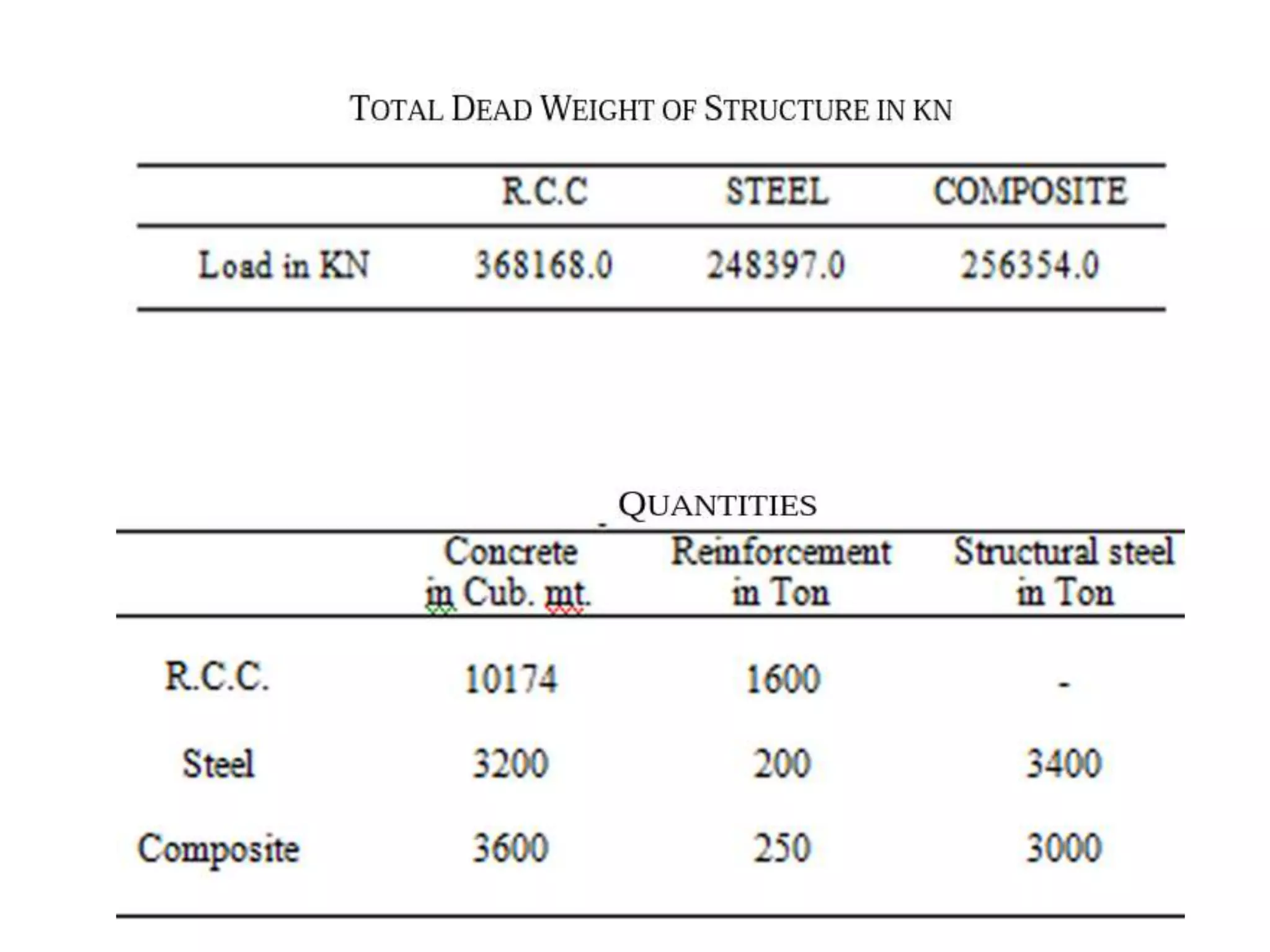

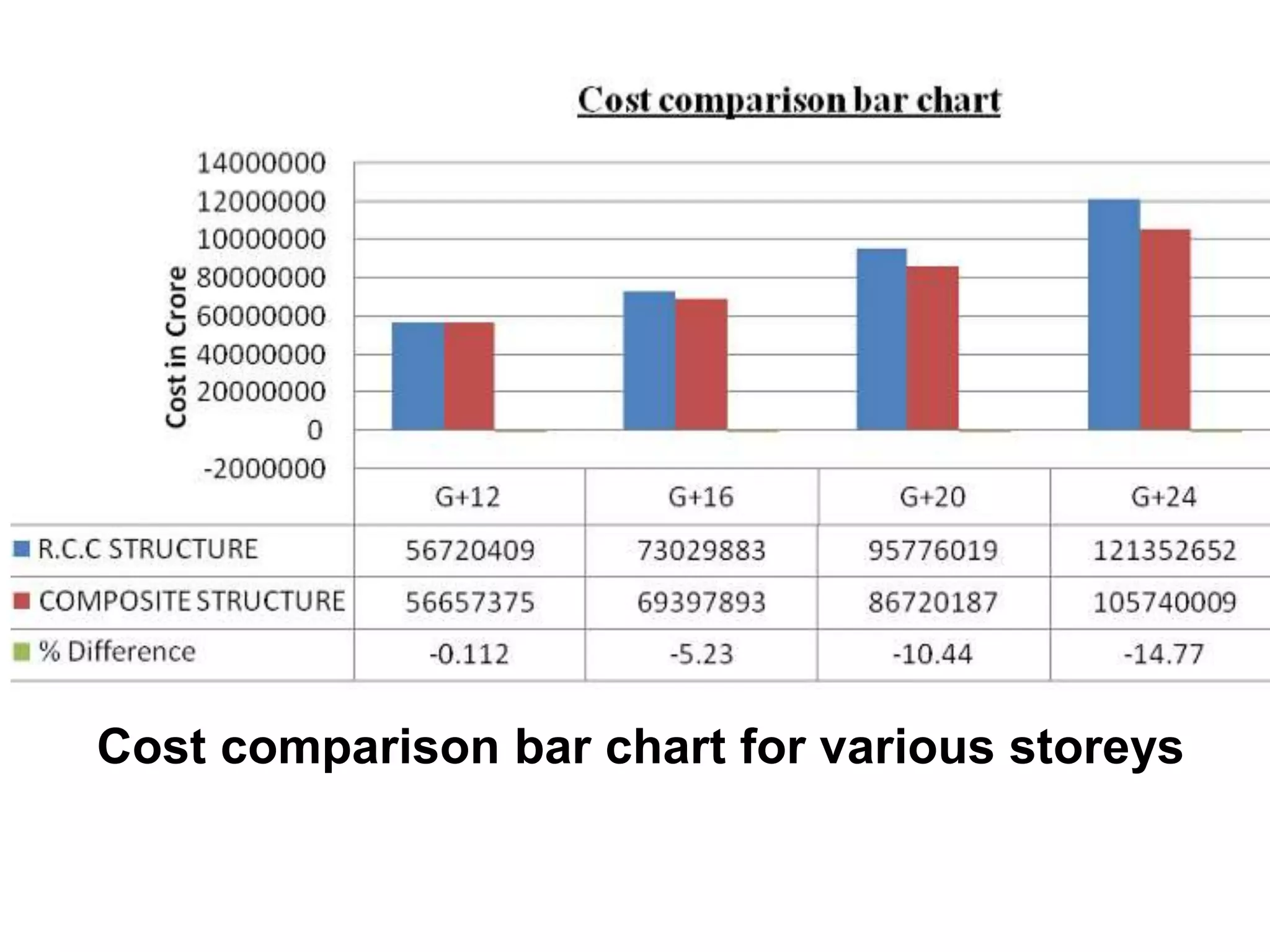

The document discusses composite construction, which integrates structural steel and reinforced concrete to create efficient building designs, particularly for high-rise structures. It highlights the advantages of composite systems, including faster construction times, improved strength, and better earthquake resistance, alongside outlining common floor types and shear connection requirements. A comparative study suggests that composite construction is superior to both RCC and steel alternatives in terms of weight reduction and overall structural ductility.