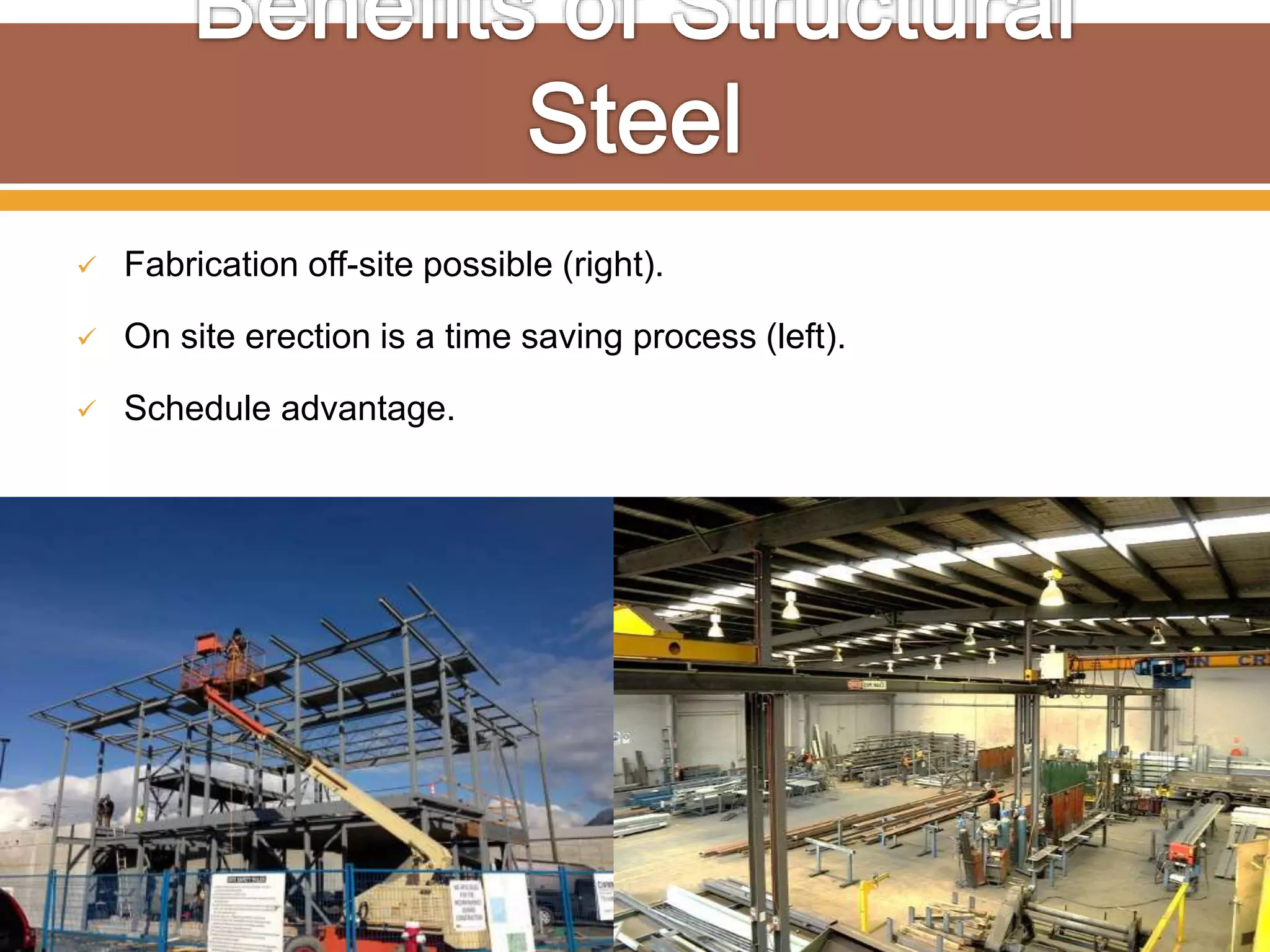

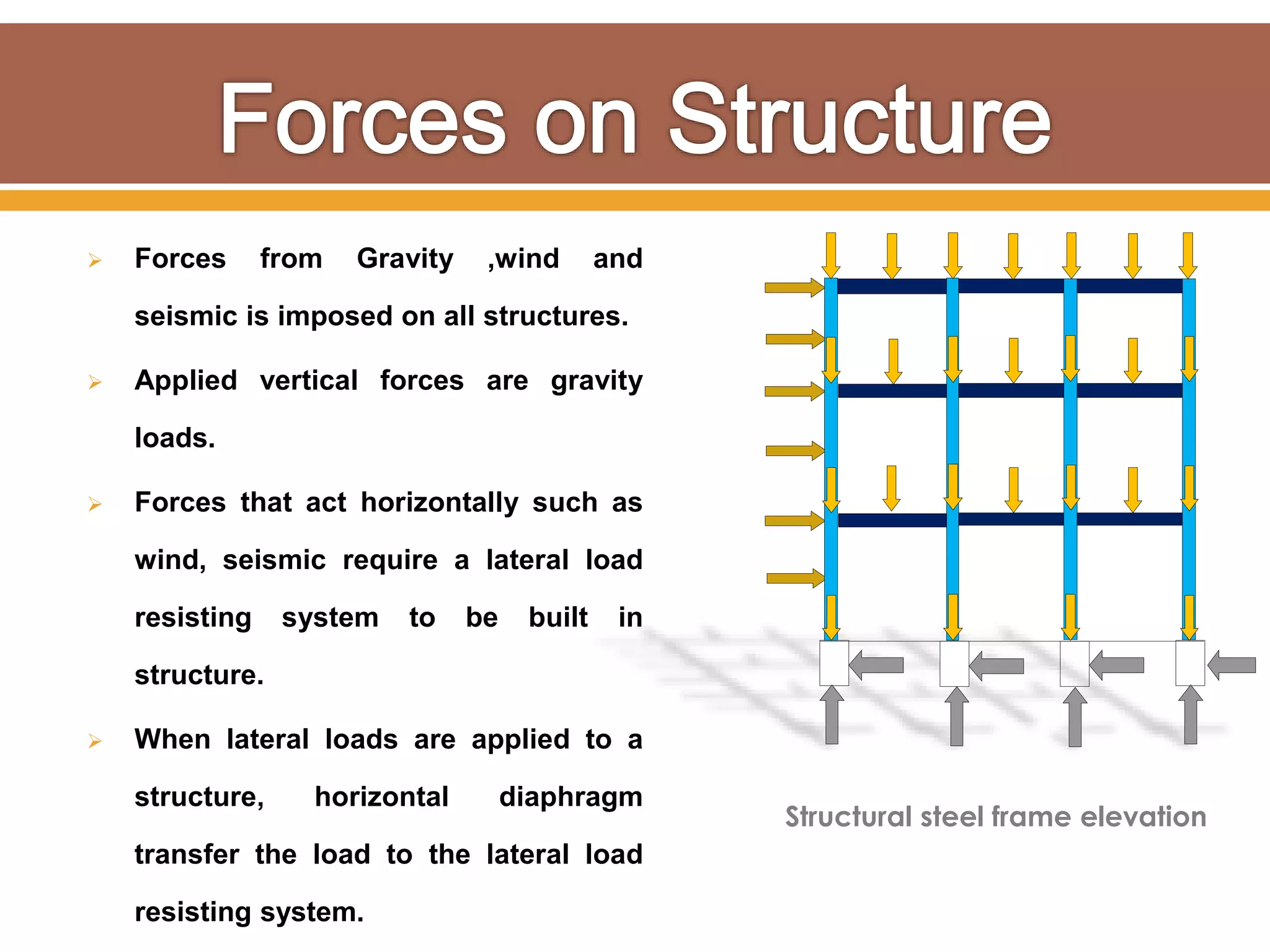

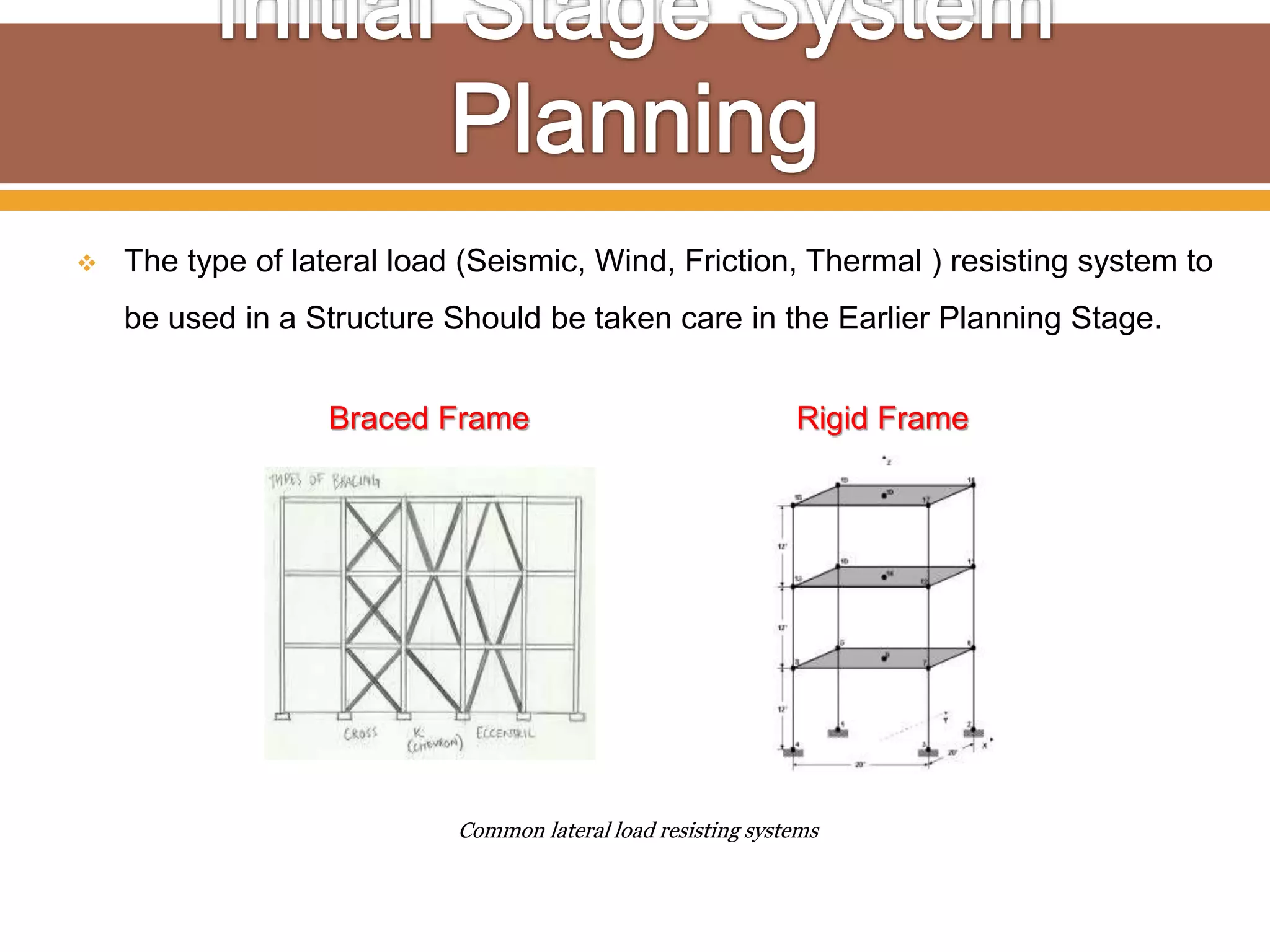

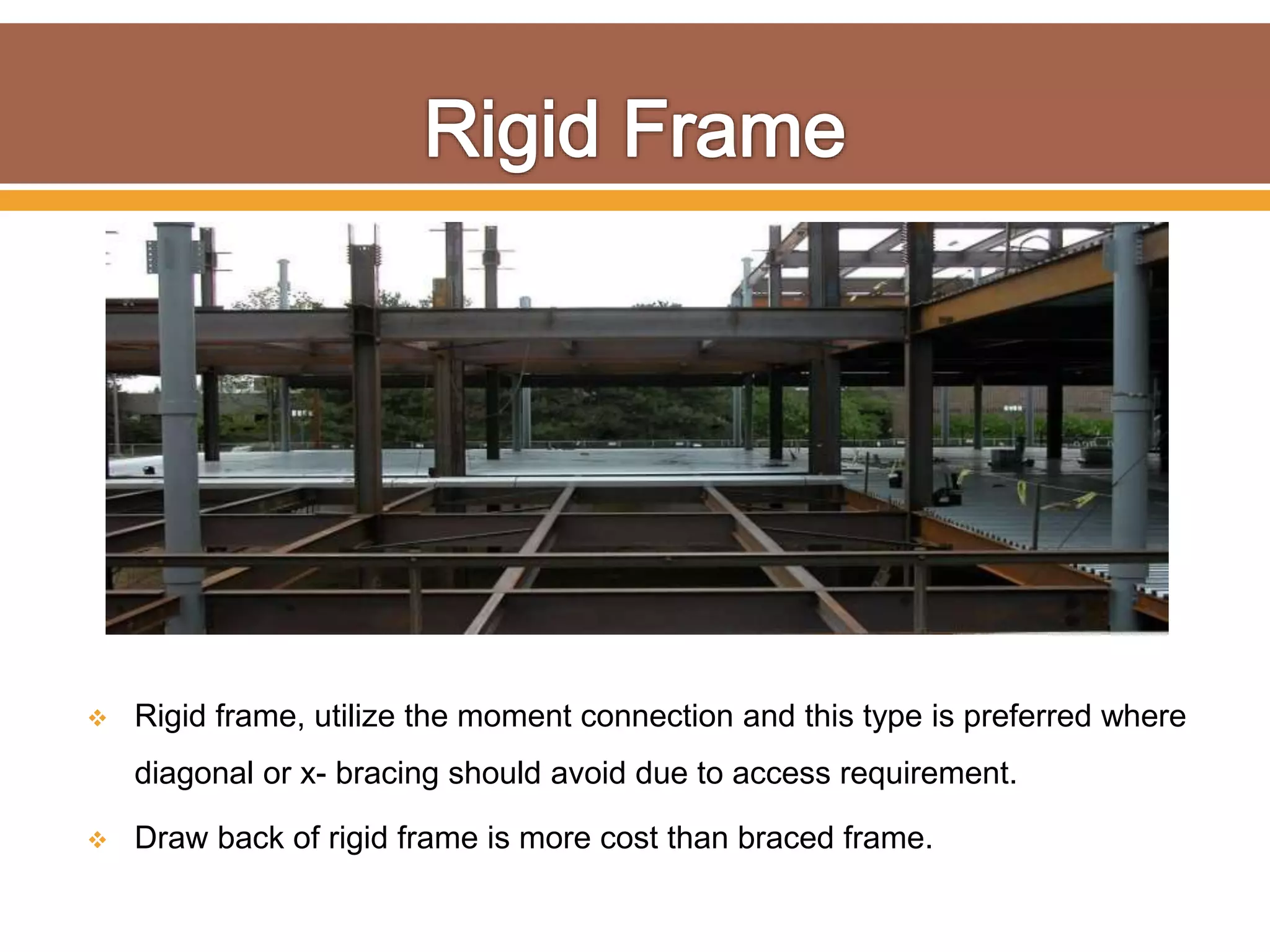

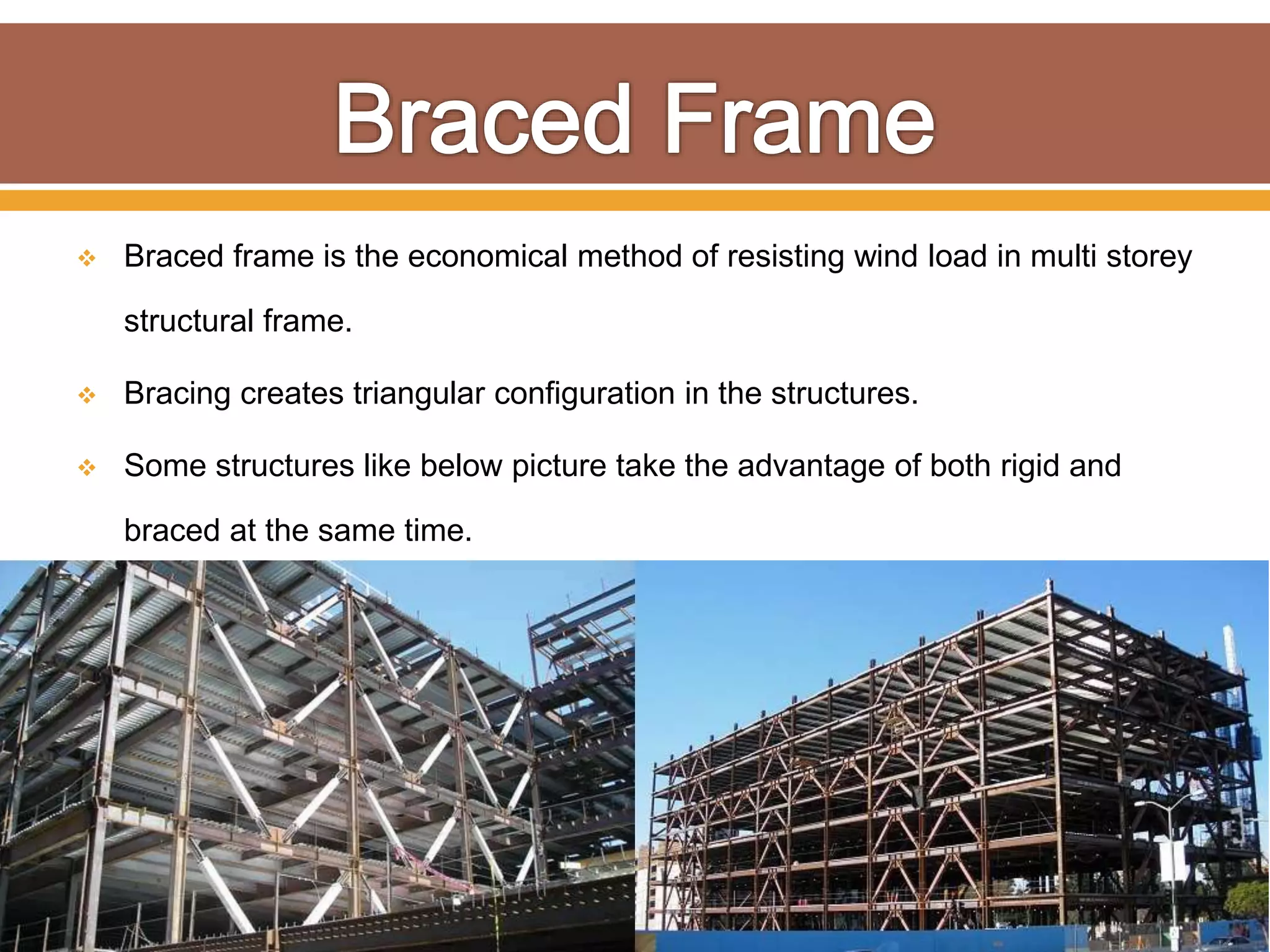

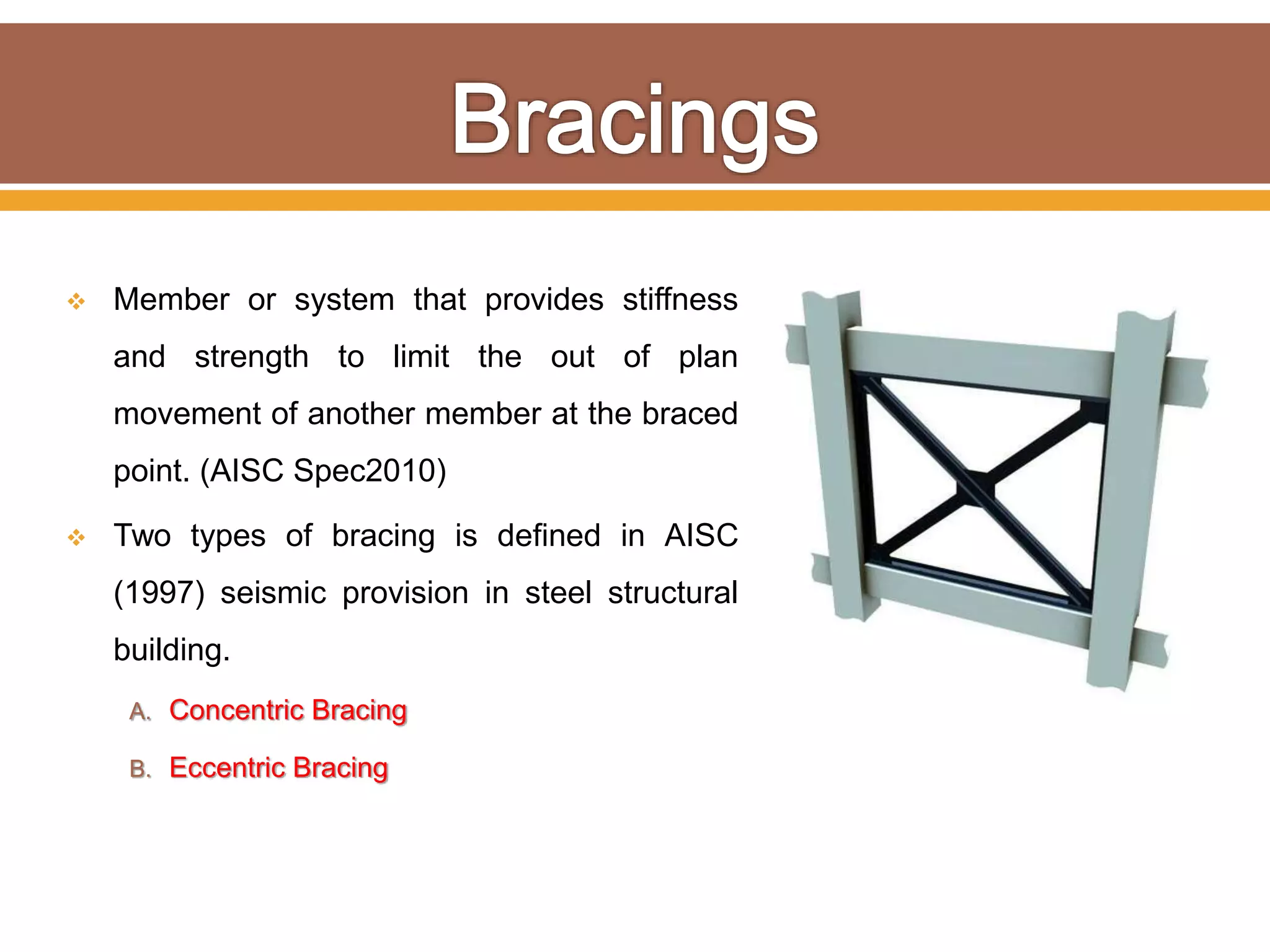

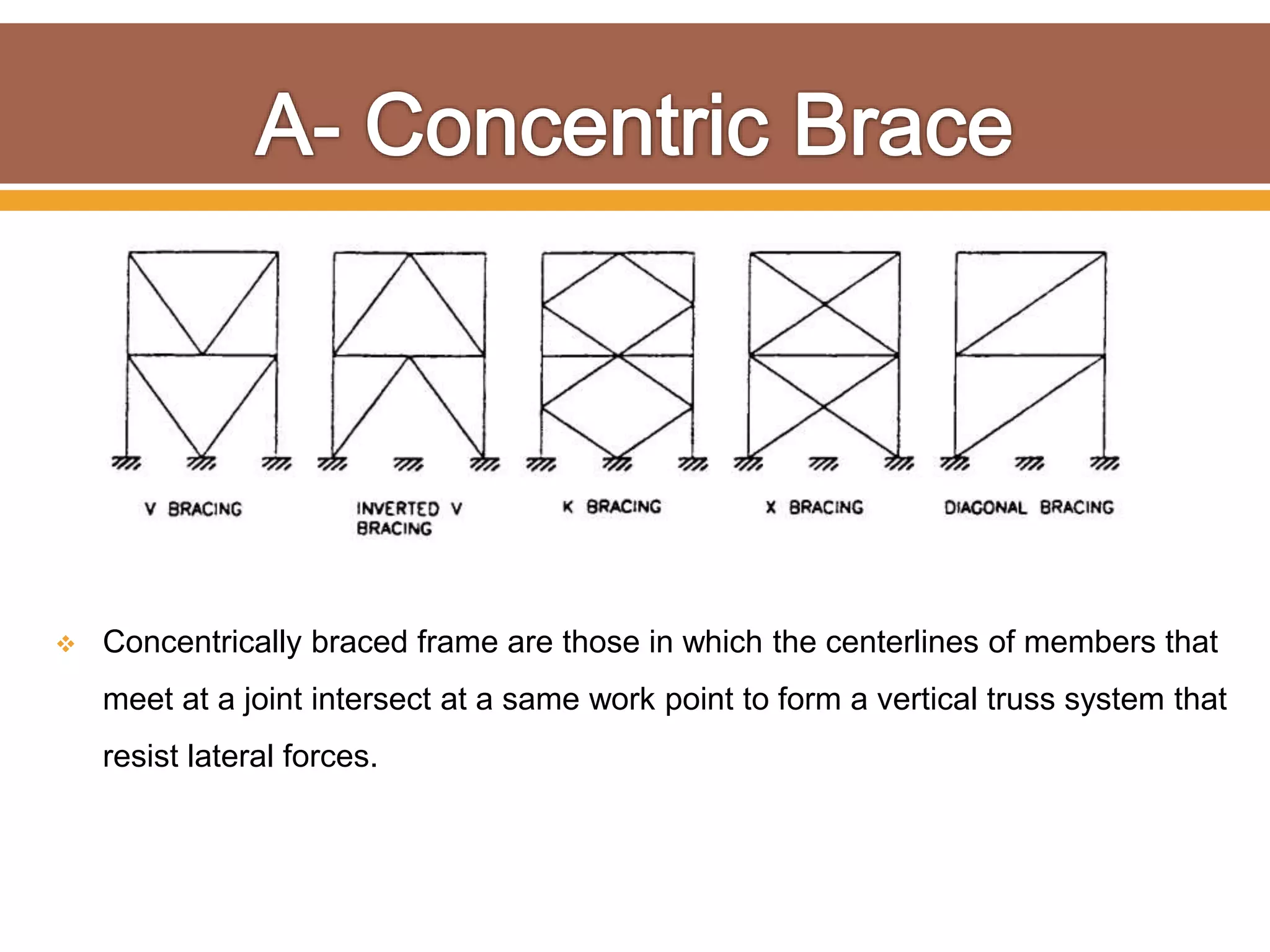

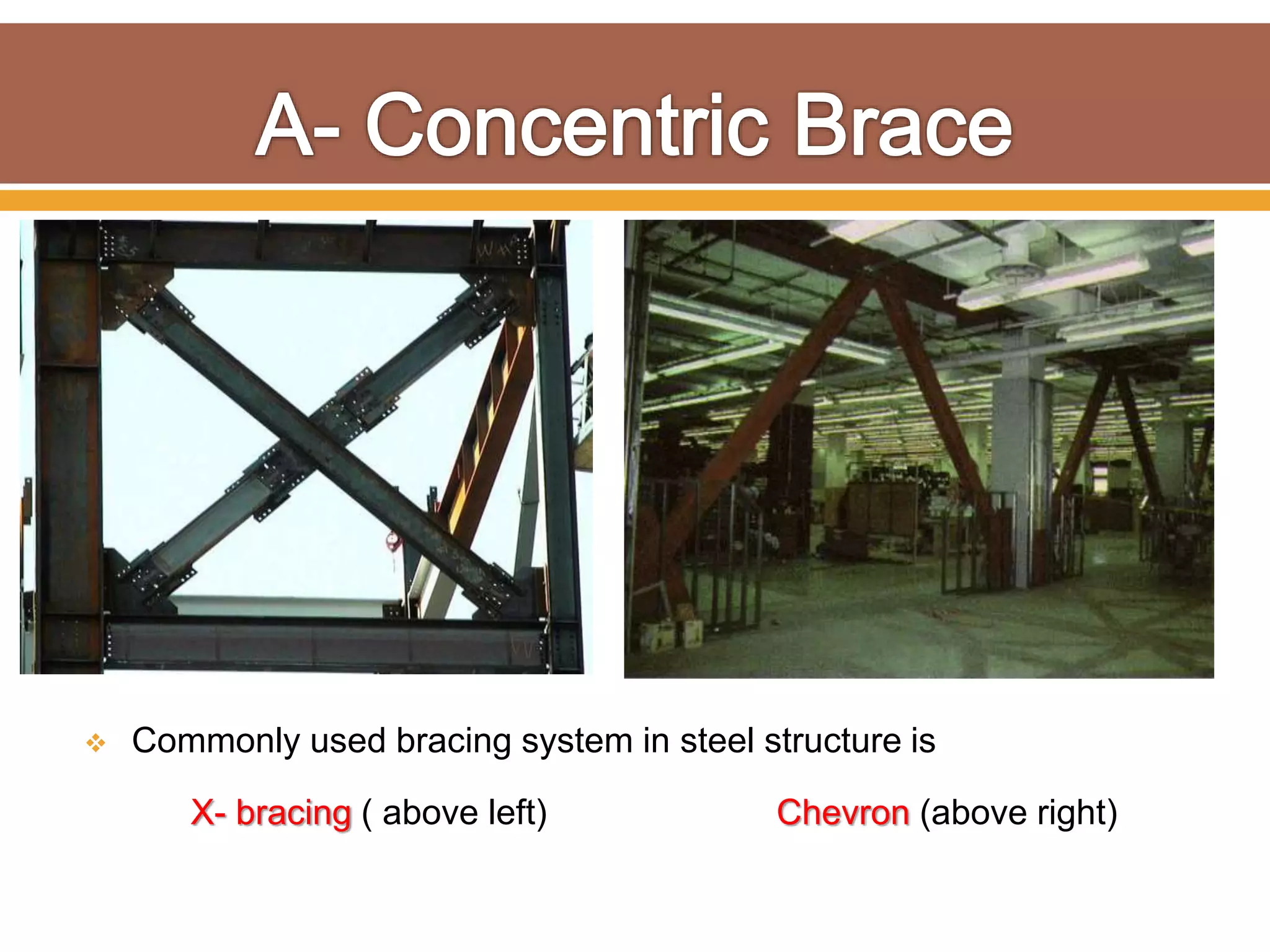

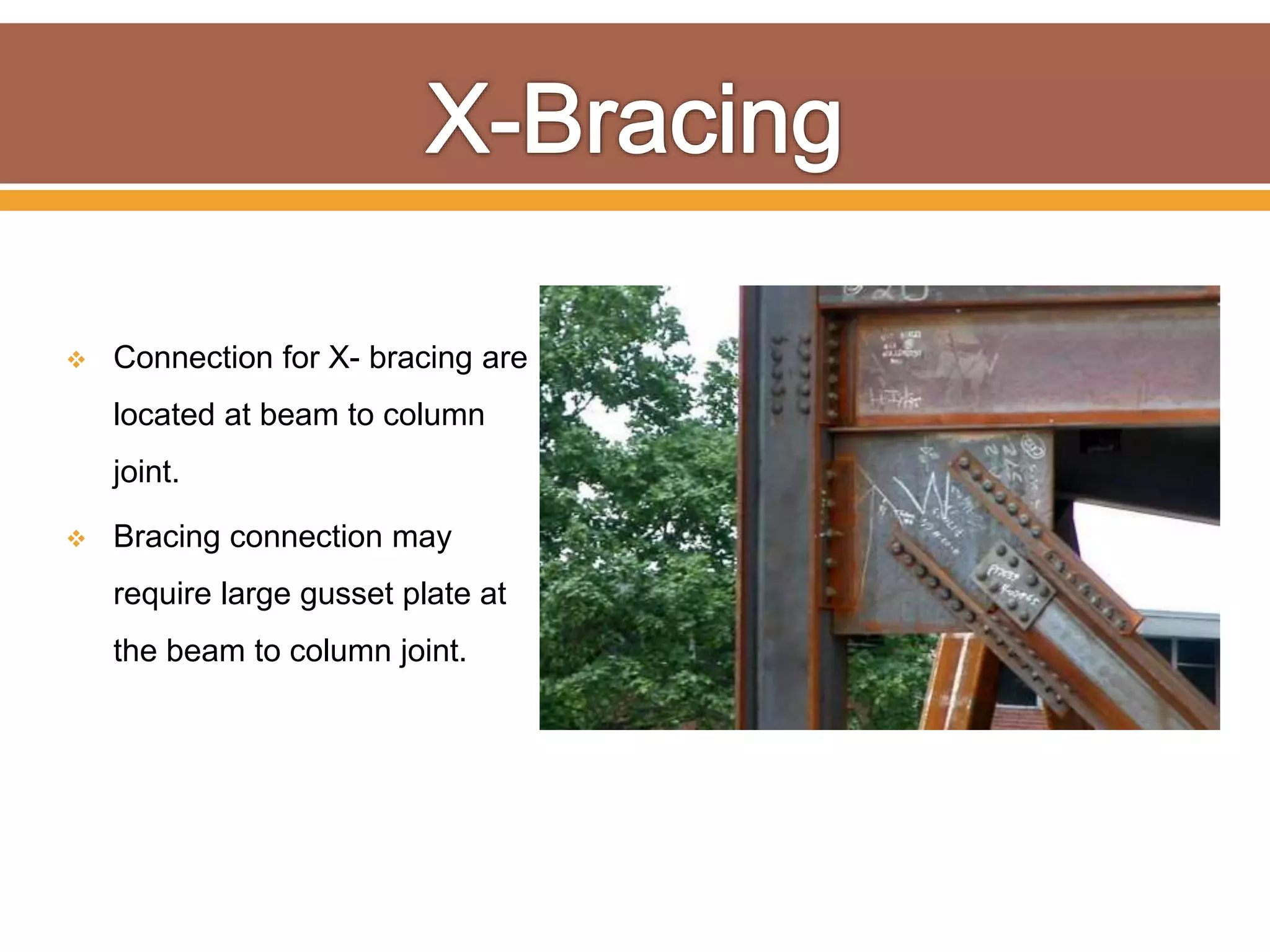

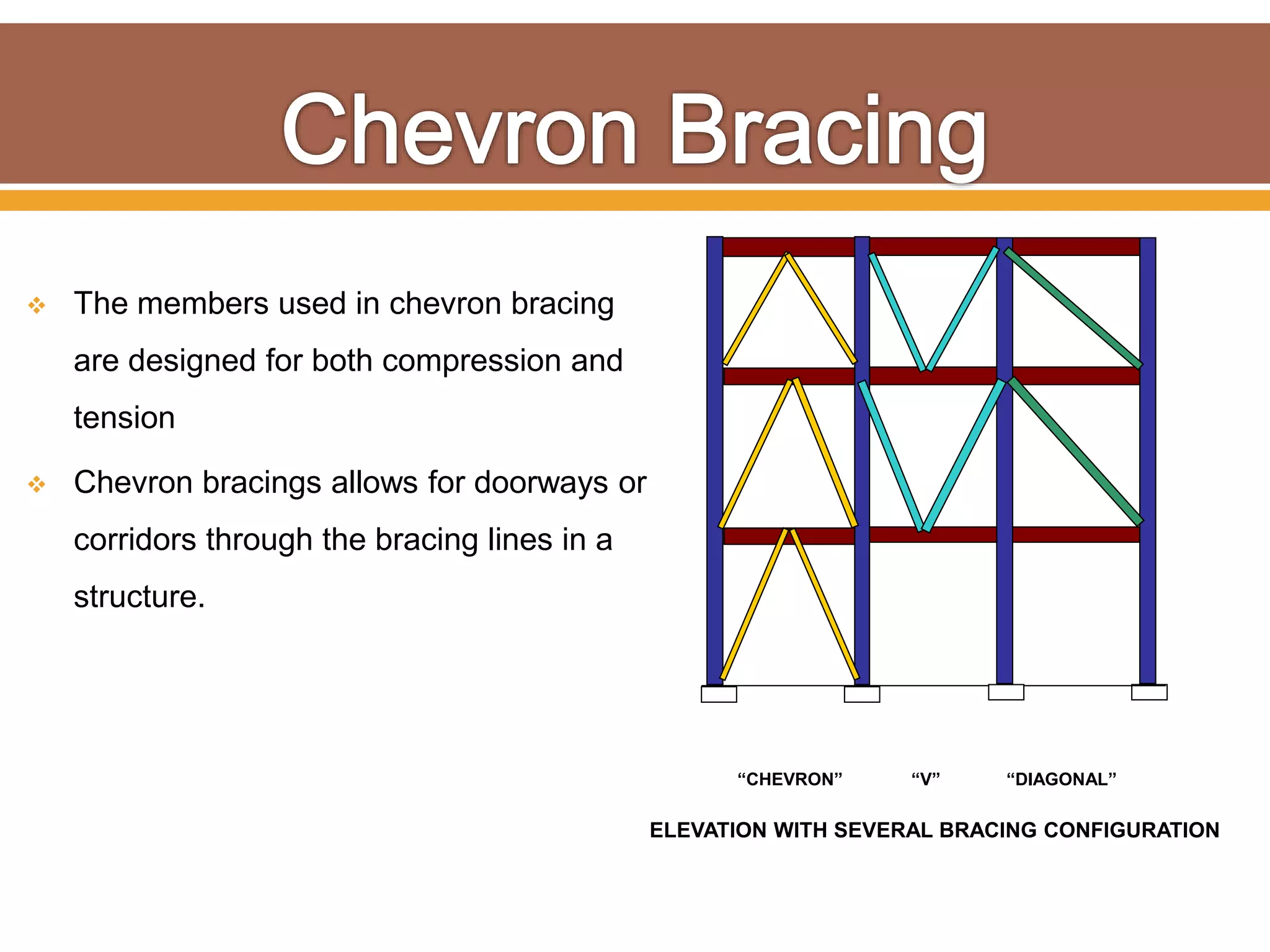

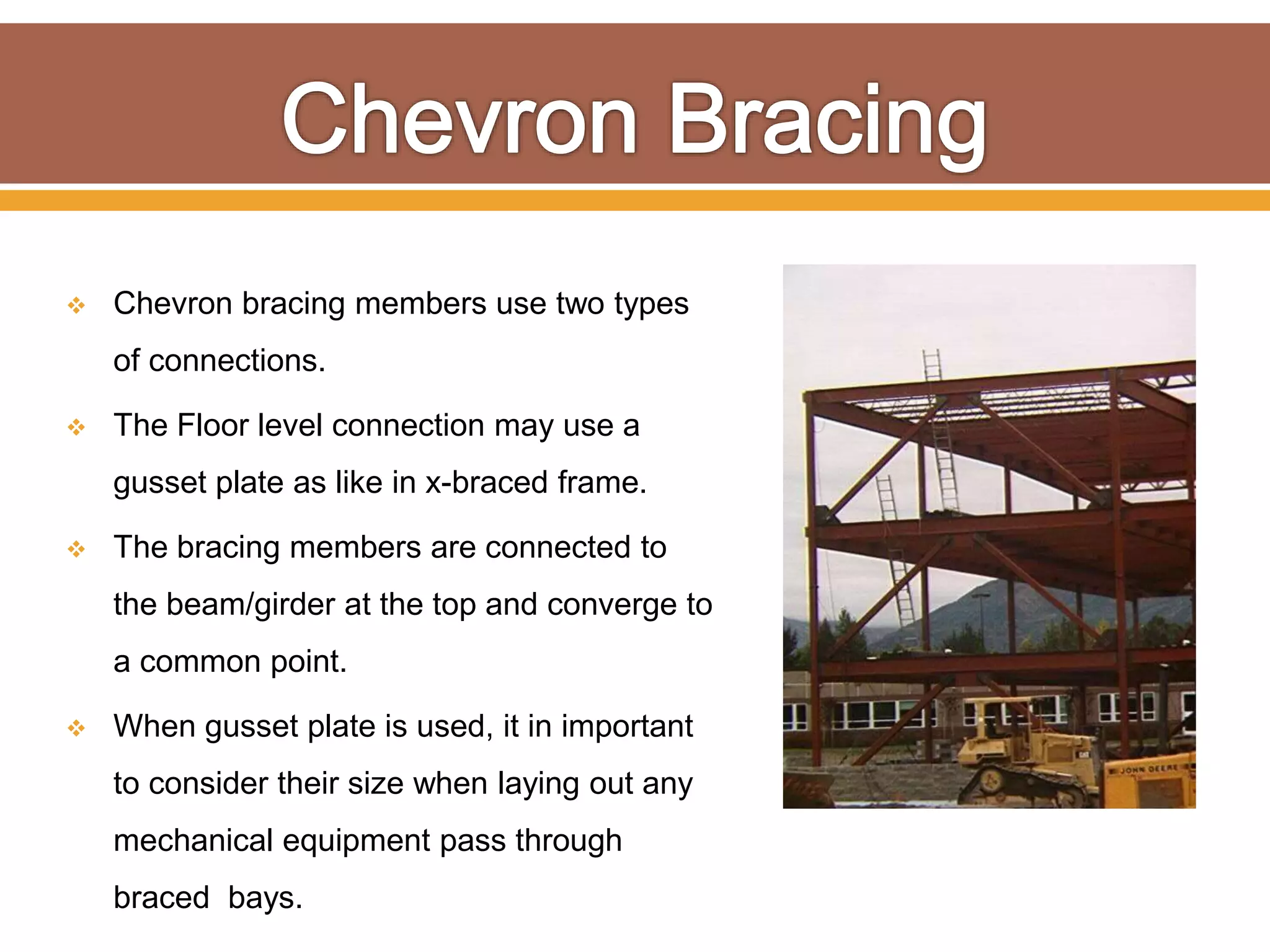

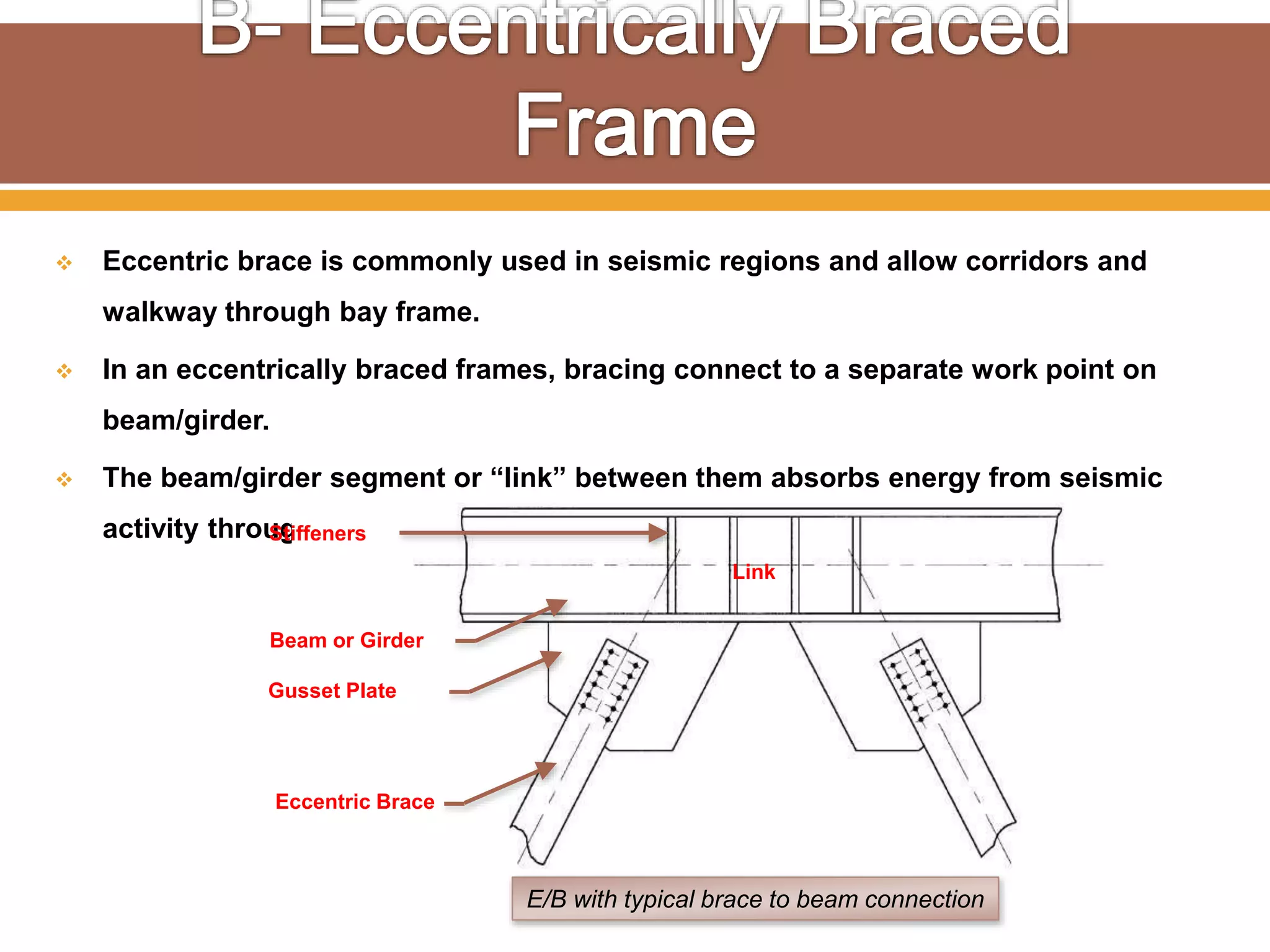

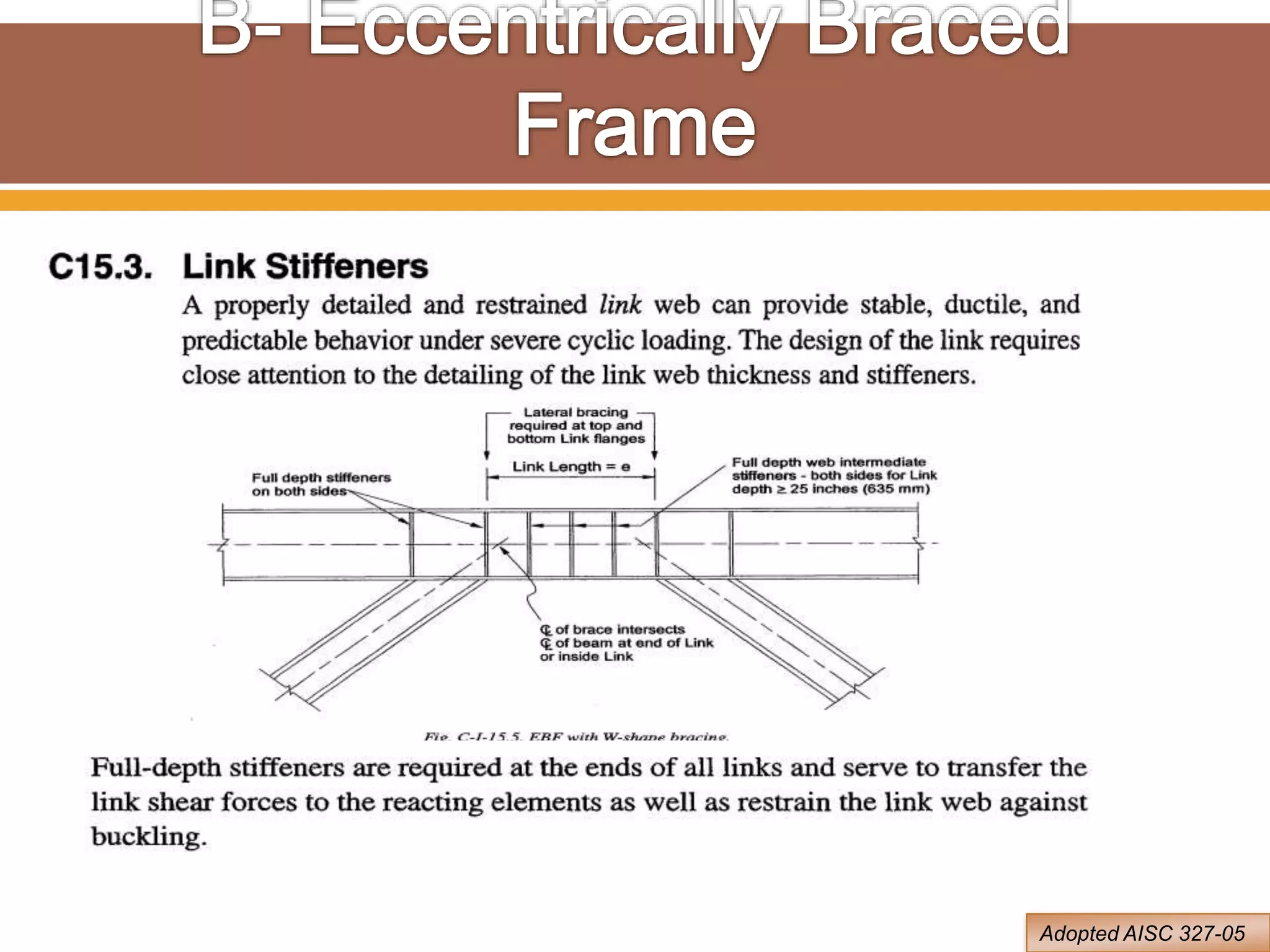

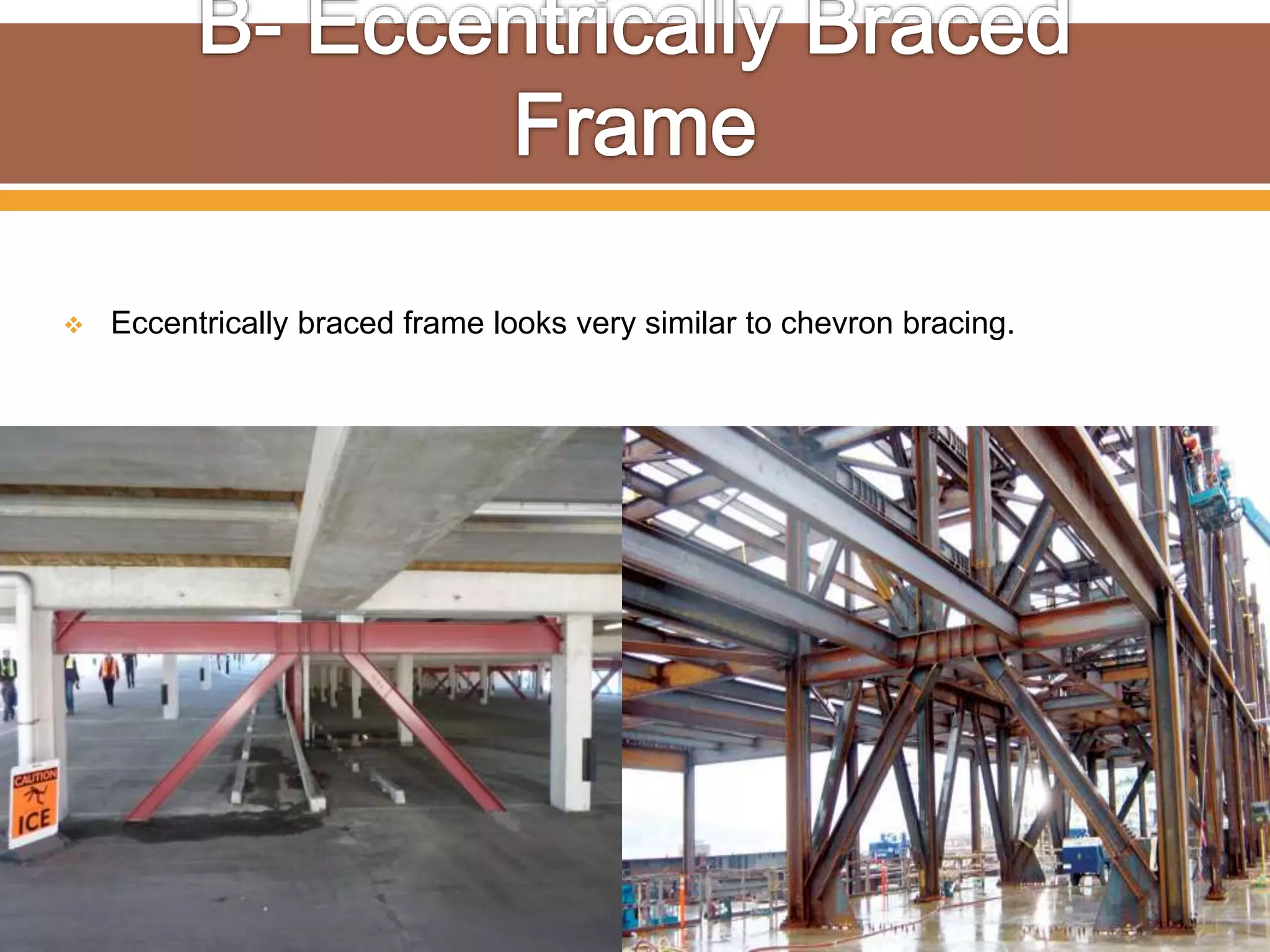

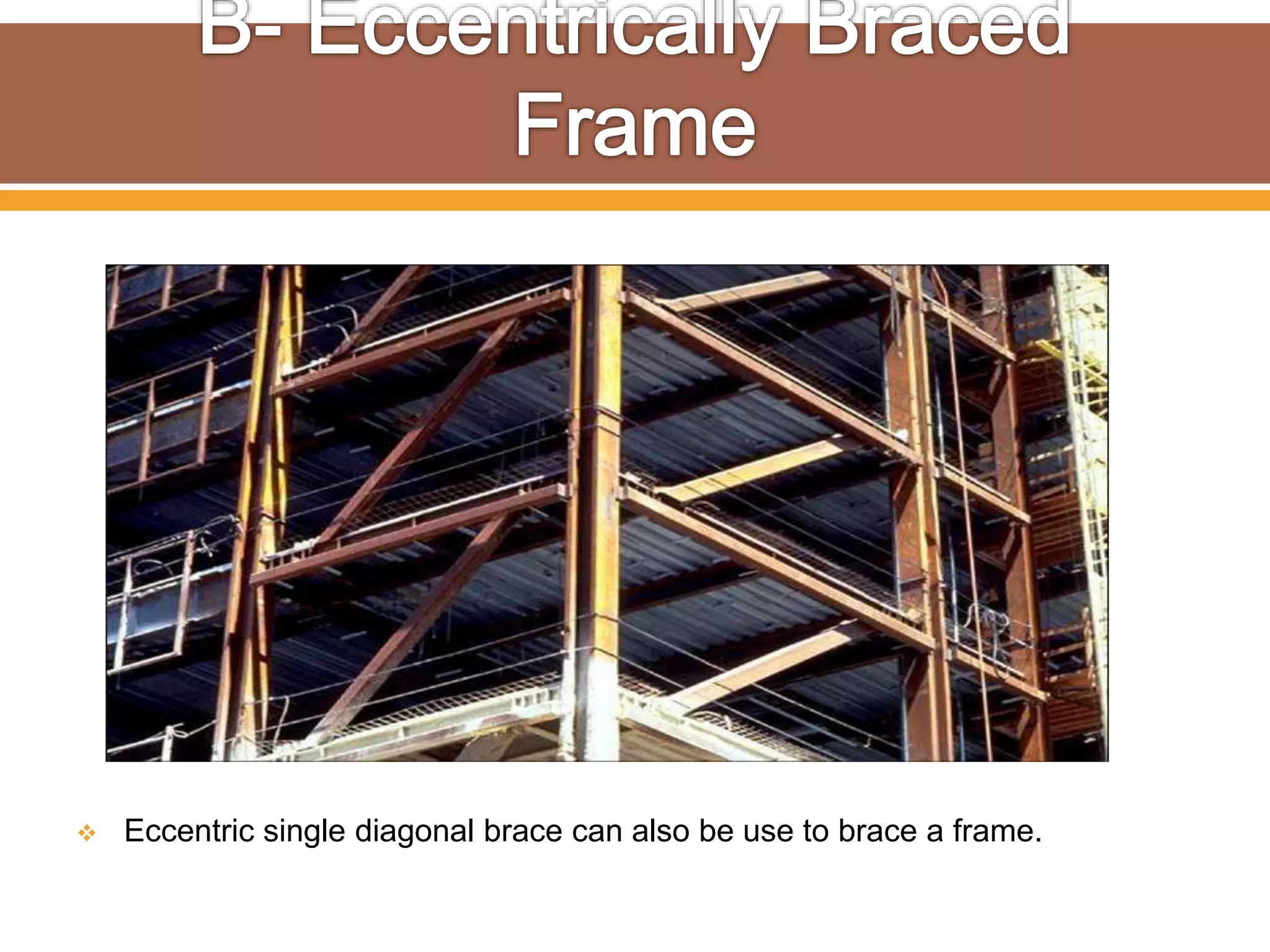

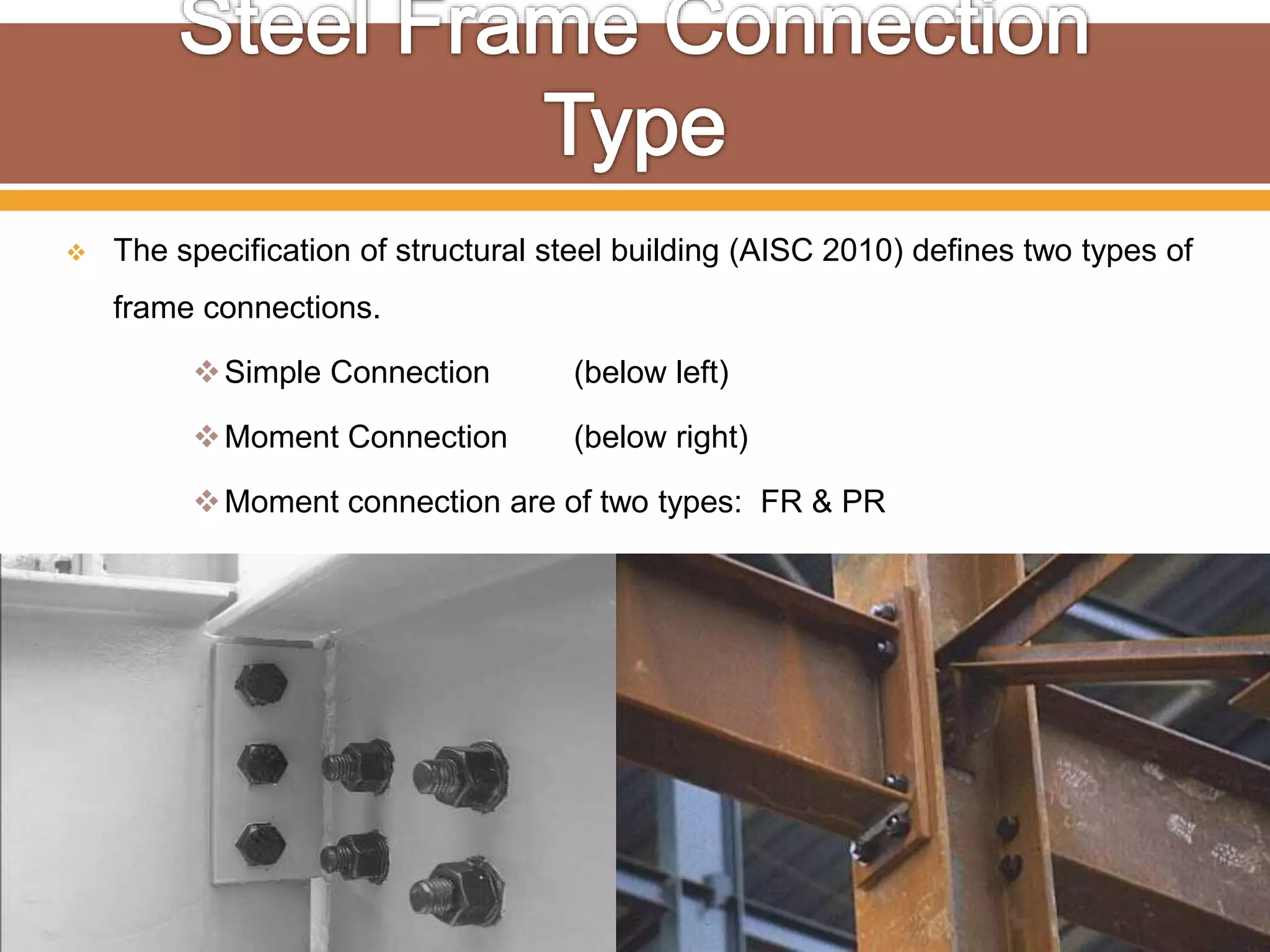

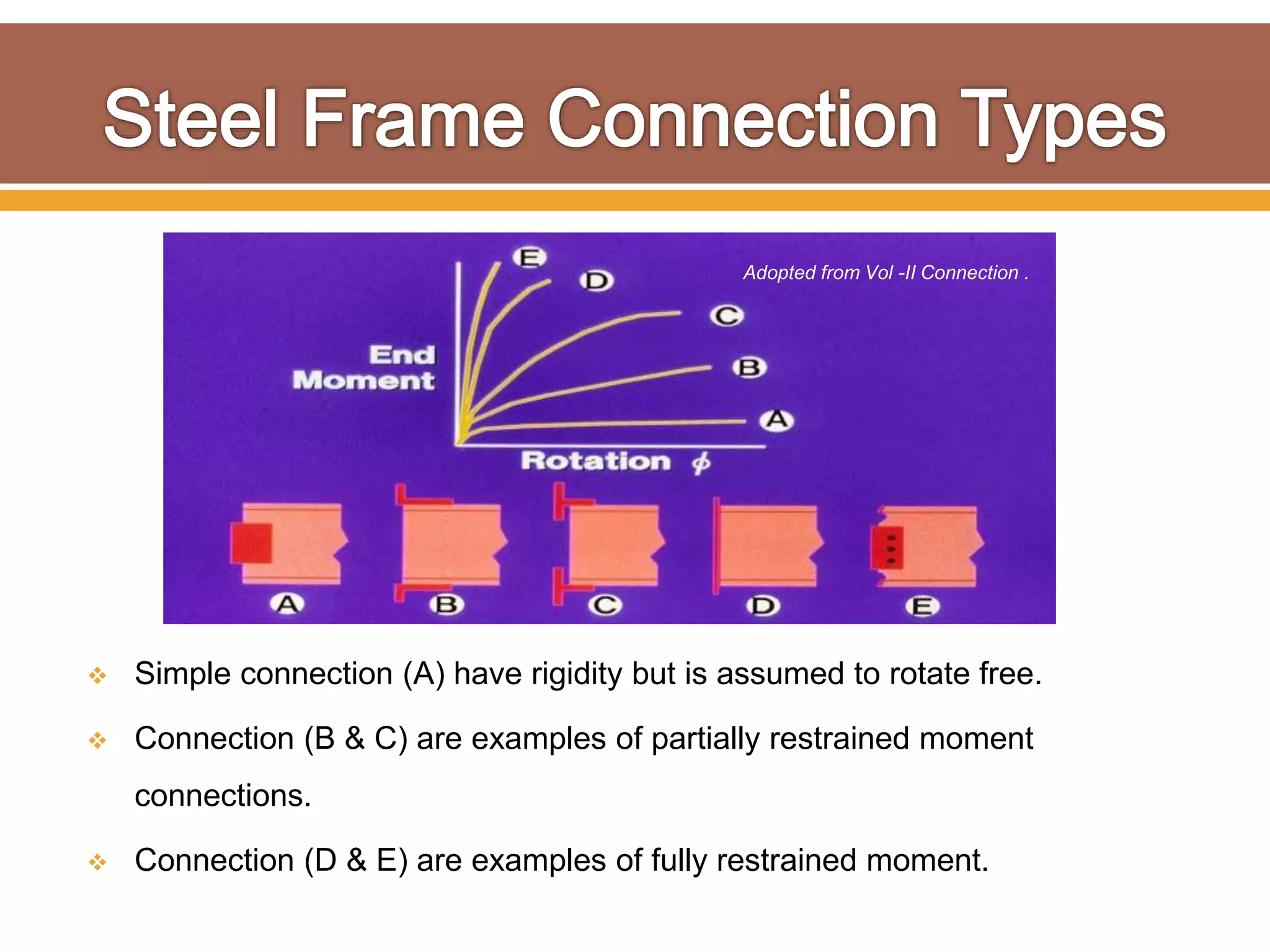

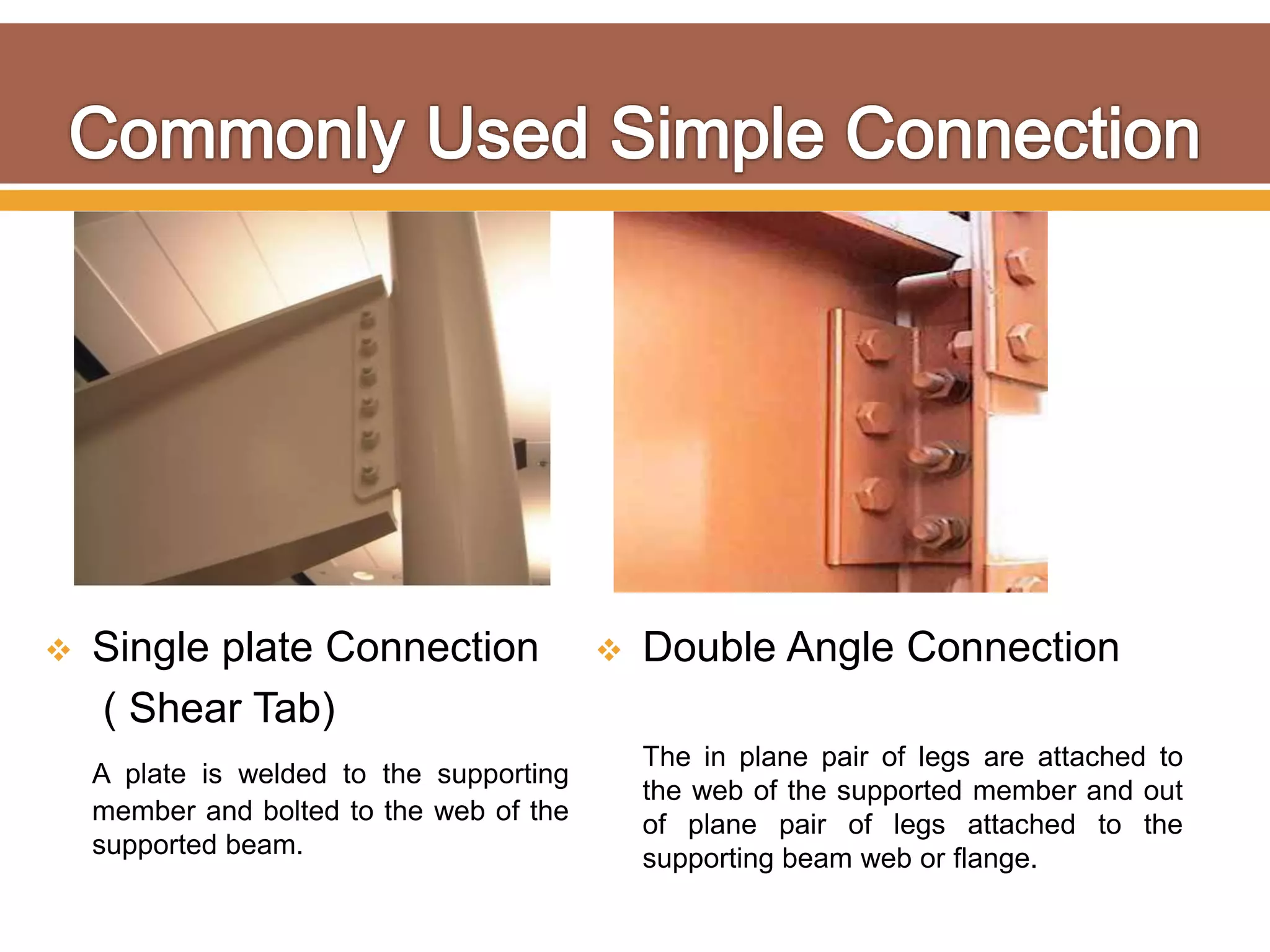

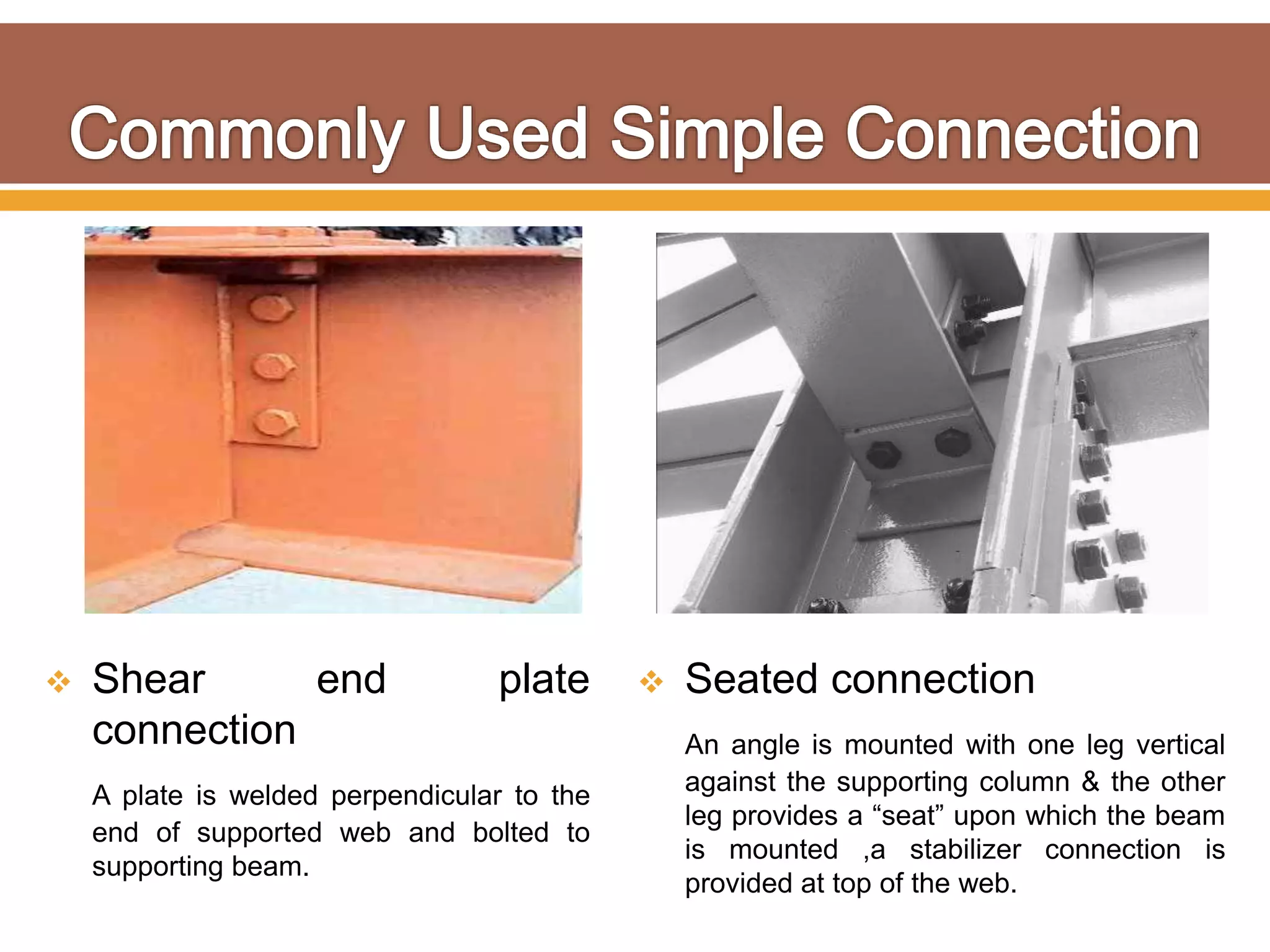

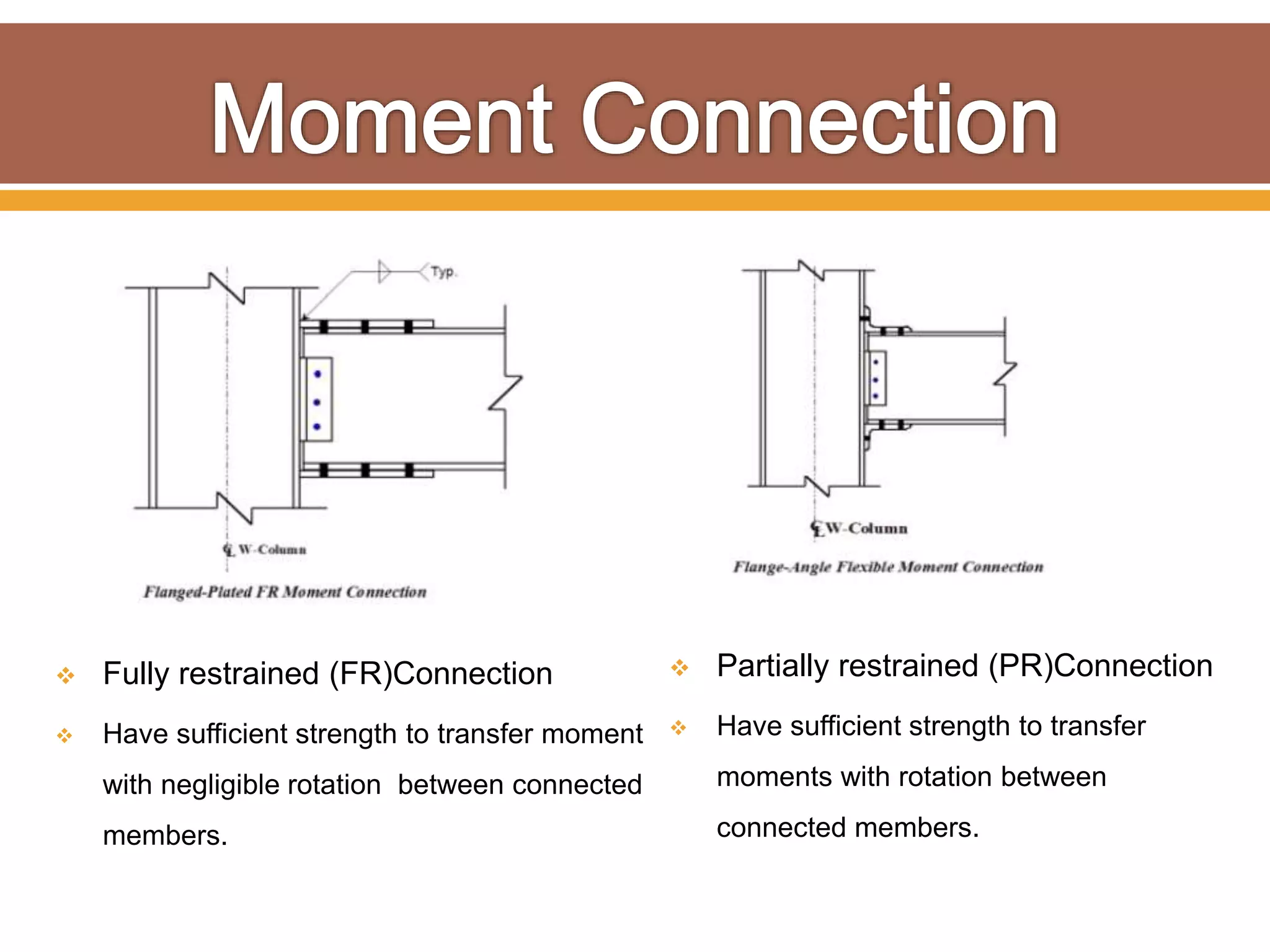

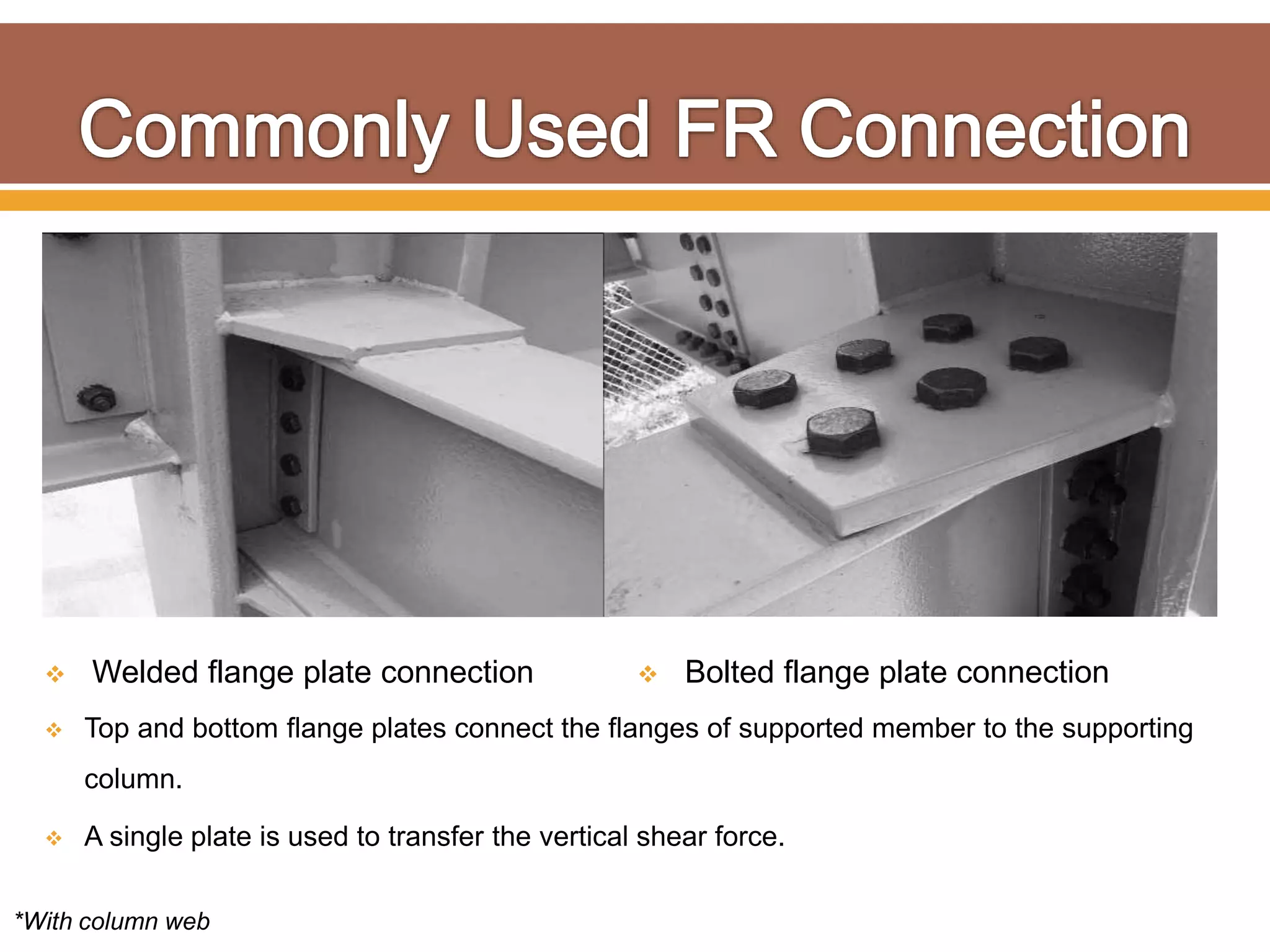

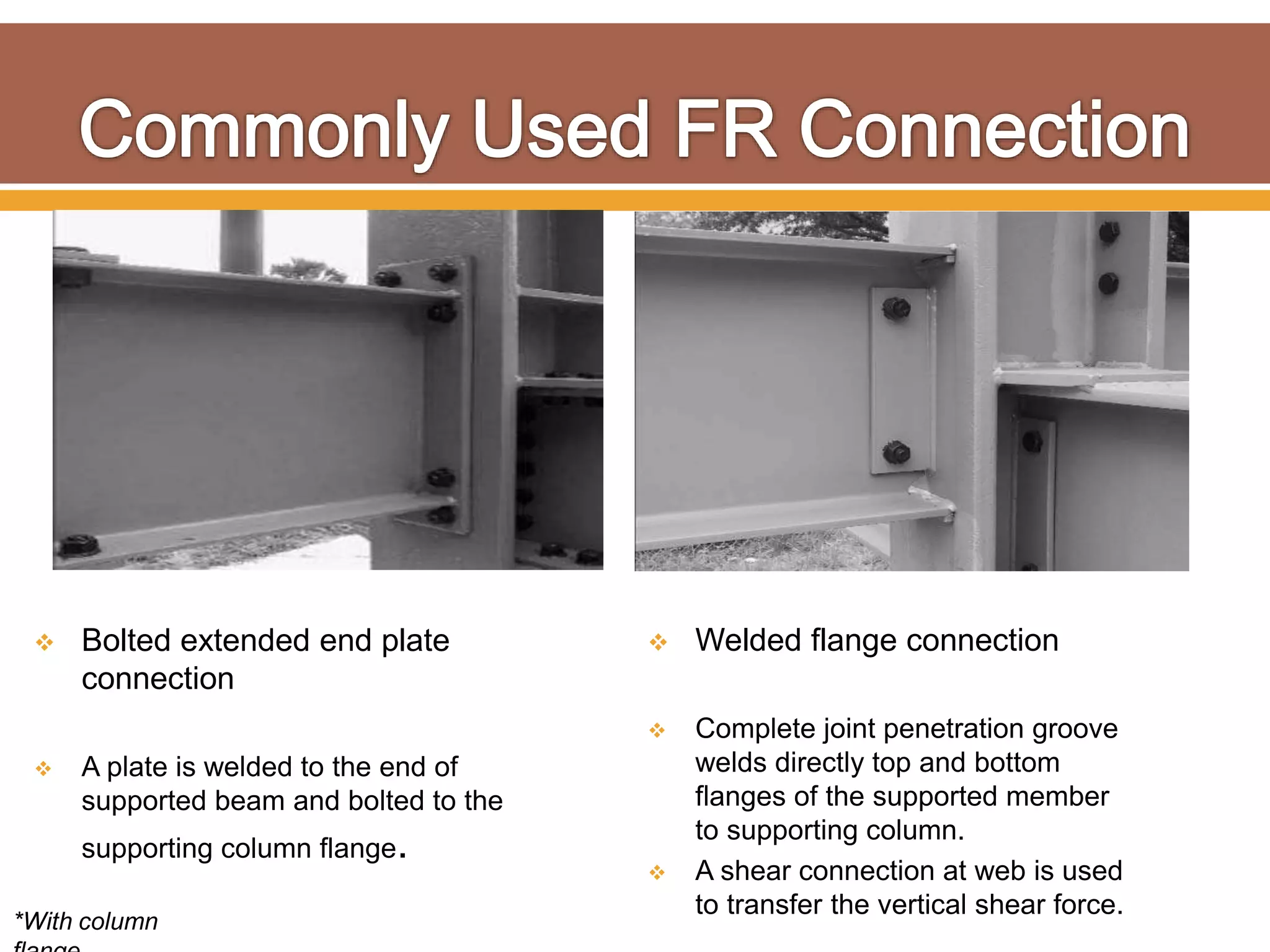

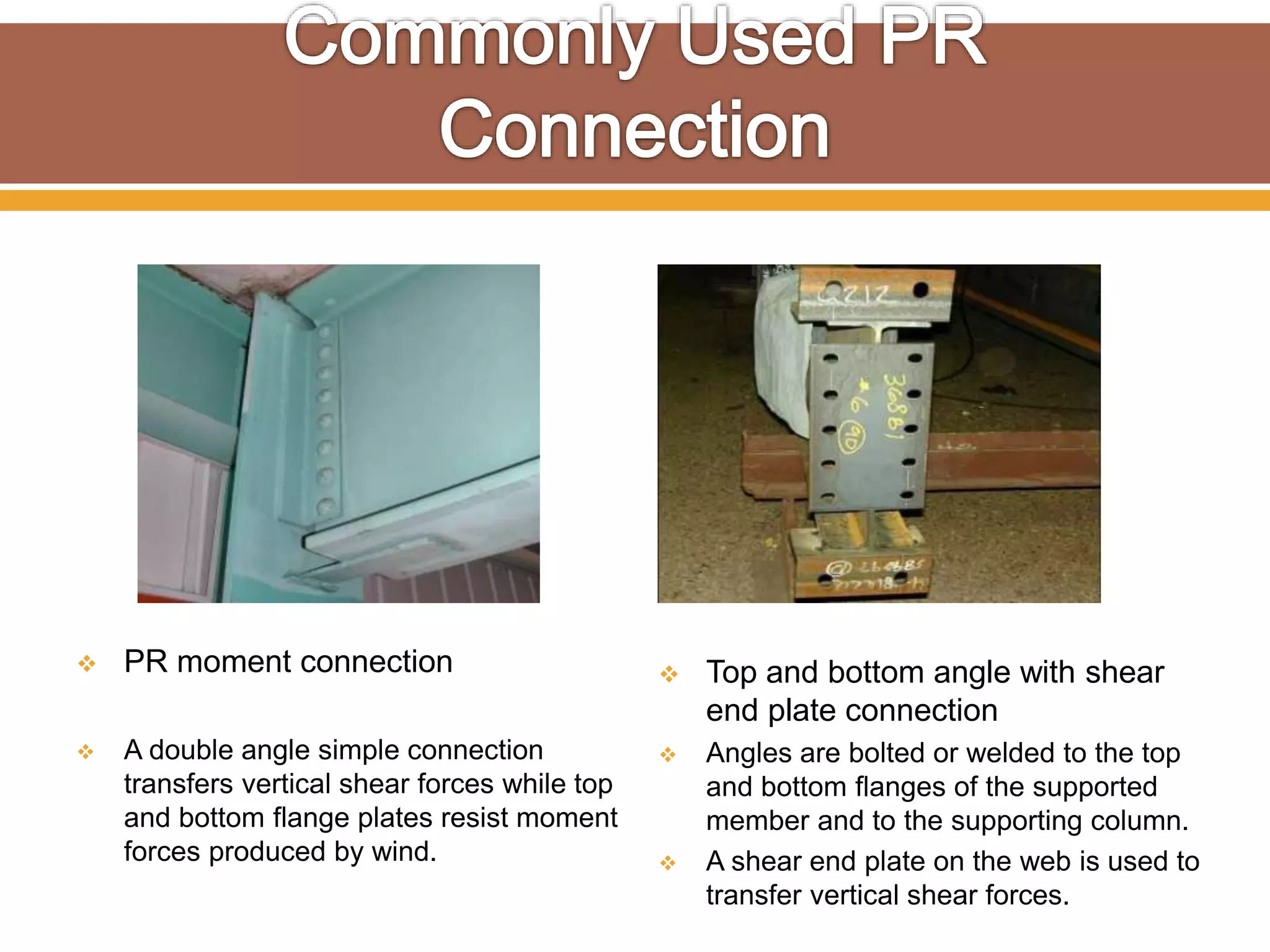

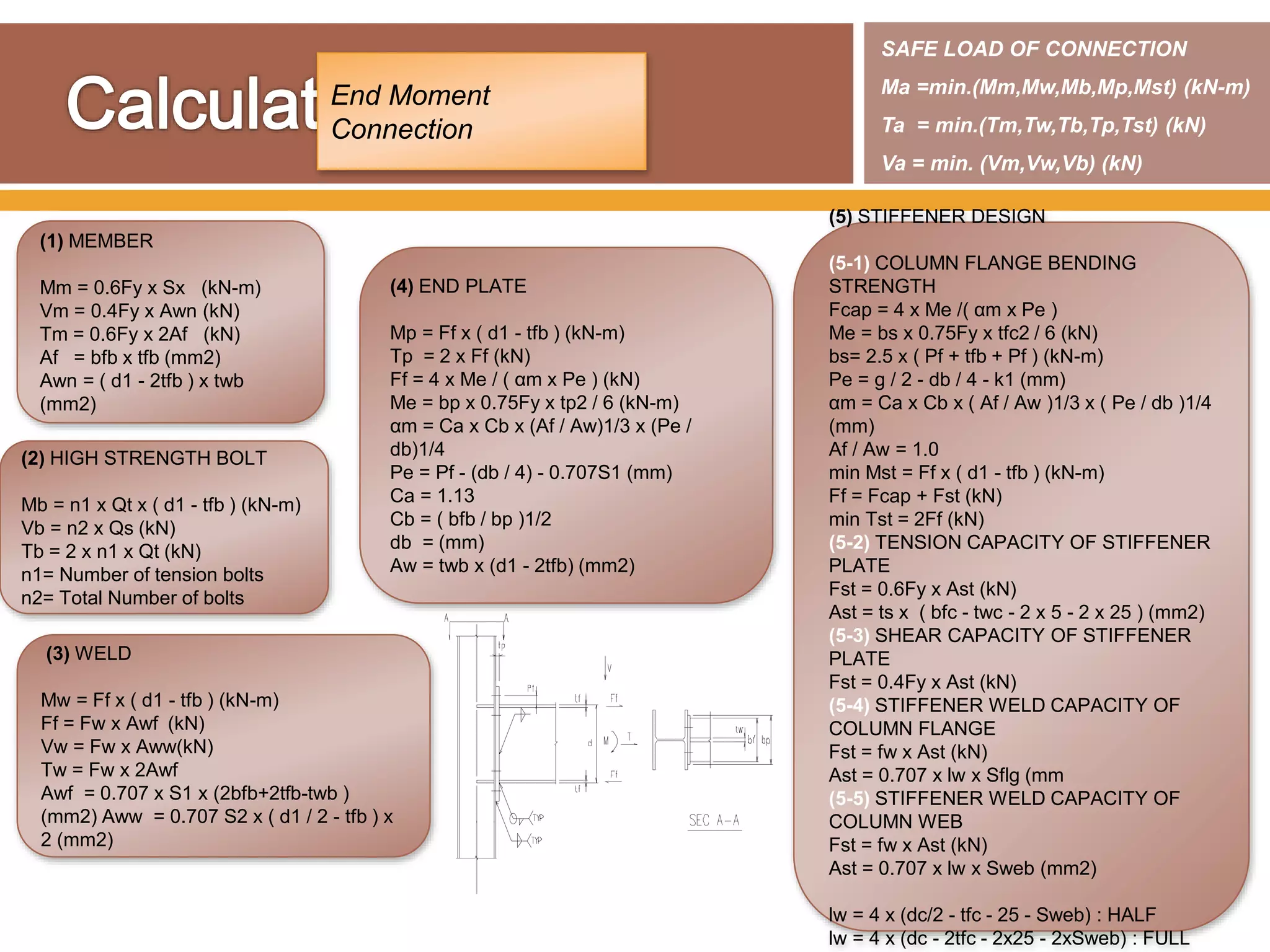

This document provides an overview of structural steel design and connections. It discusses the benefits of steel structures, common lateral load resisting systems like braced and rigid frames, and types of bracing configurations. It also examines different types of steel frame connections including simple, moment, and eccentric braced connections. Design considerations and capacity equations for moment connections are presented.