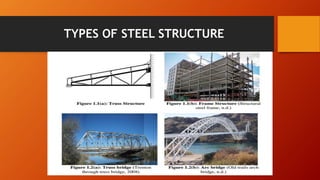

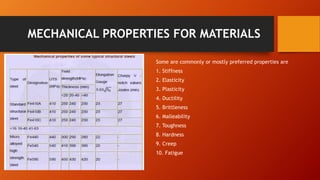

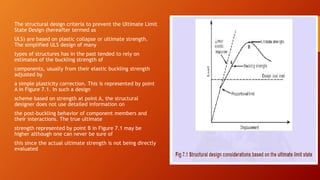

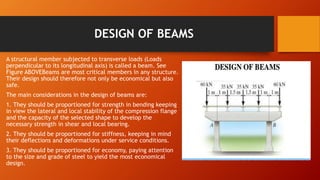

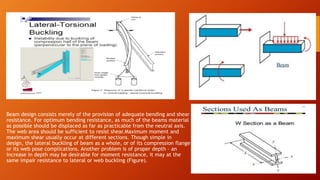

This document provides an overview of steel structure design. It discusses the types of steel structures like truss, frame, grid and arch structures. It describes the methodology of steel design using Allowable Strength Design and Load and Resistance Factor Design. It discusses the mechanical properties of steel, concepts of limit state design for beam columns, and connections. It also provides details on the design of beams, including classifications of beams and the main considerations in beam design.