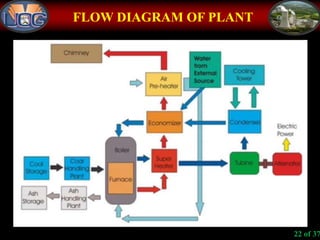

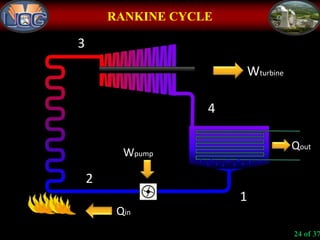

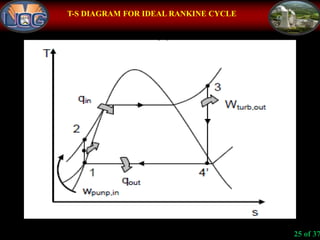

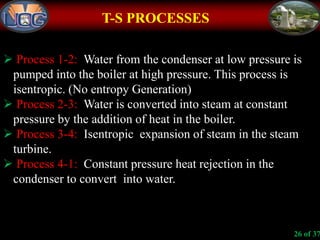

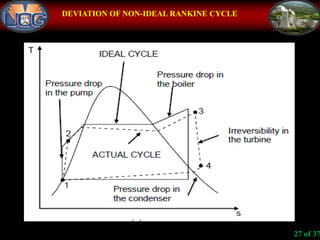

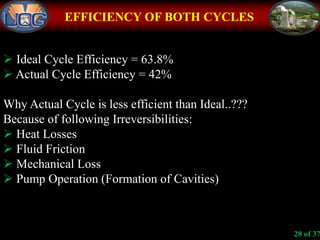

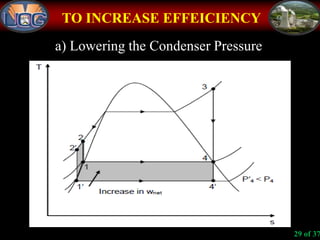

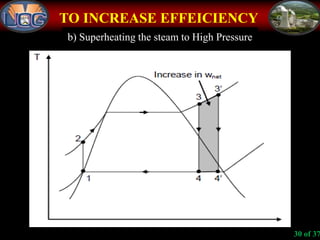

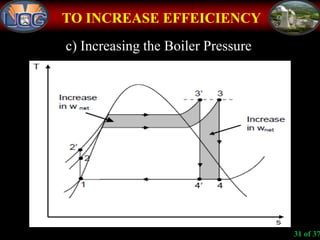

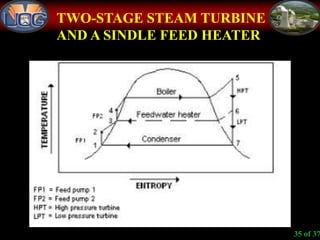

This document provides an overview of a steam power plant. It discusses the history and development of steam engines and turbines for power generation. It then describes the key components of a steam power plant, including the boiler, turbine, condenser, and generator. The document explains that steam power plants operate on the Rankine cycle, where water is heated to steam to drive the turbine, then condensed back to water to be reheated. It provides diagrams of the ideal and actual Rankine cycles and discusses methods to increase the efficiency of the plant.

![HISTORY

The initially developed reciprocating steam engineer has been used to

produce mechanical power since the 18th Century, with notable

improvements being made by James Watt. When the first commercially

developed central electrical power stations were established in 1882

at Pearl Street Station in New York and Holborn Viaduct power

station in London, reciprocating steam engines were used. The

development of the steam turbine in 1884 provided larger and more

efficient machine designs for central generating stations. By 1892 the

turbine was considered a better alternative to reciprocating

engines;[2] turbines offered higher speeds, more compact machinery,

and stable speed regulation allowing for parallel synchronous operation

of generators on a common bus. After about 1905, turbines entirely

replaced reciprocating engines in large central power stations

10 of 37](https://image.slidesharecdn.com/steampowerplant-170123200004/85/Steam-power-plant-10-320.jpg)