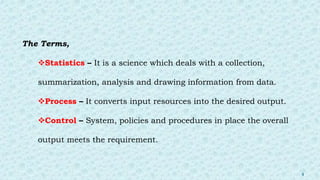

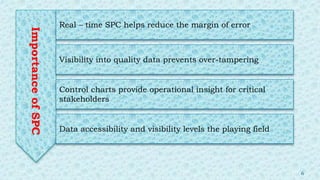

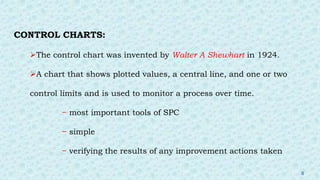

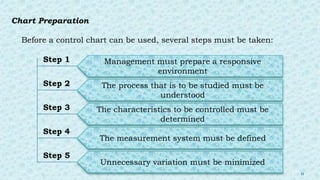

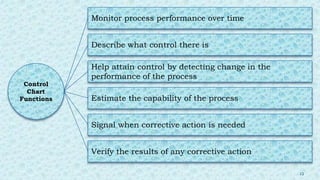

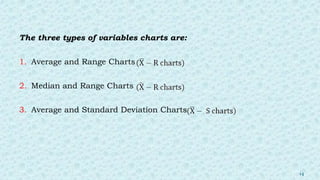

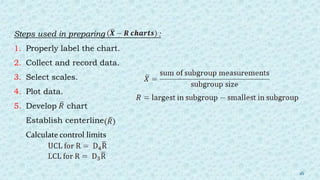

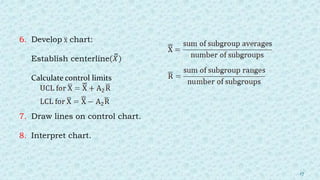

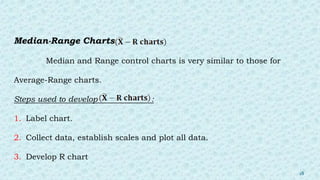

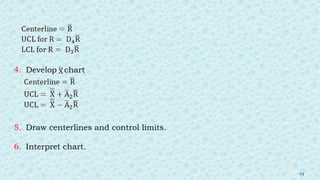

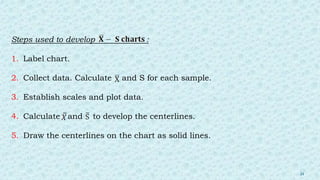

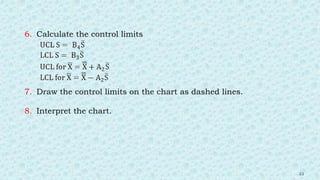

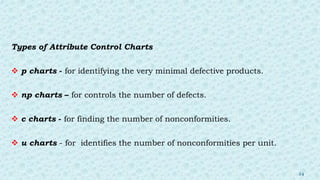

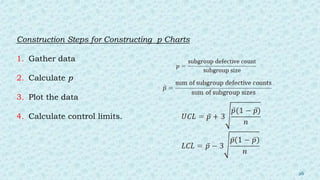

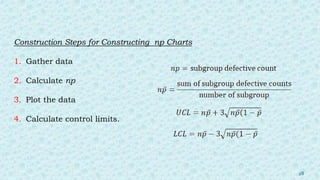

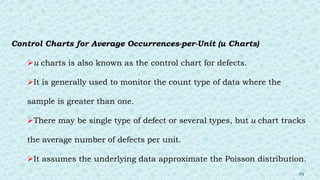

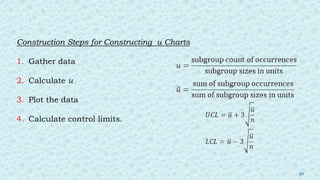

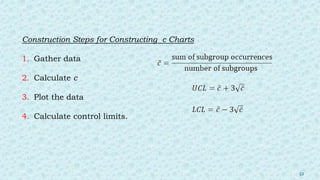

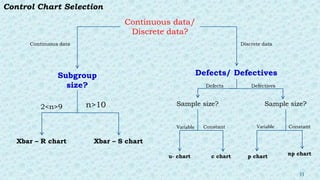

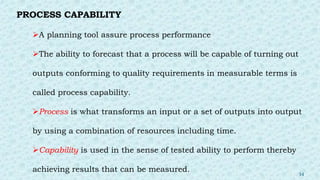

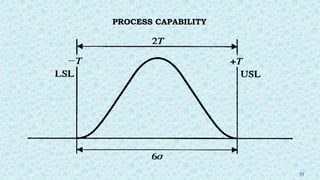

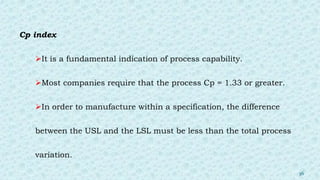

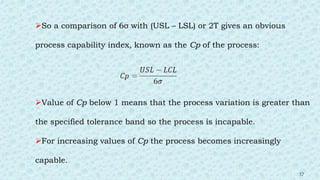

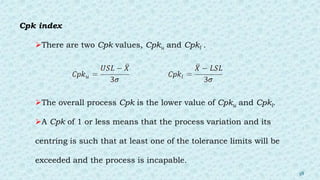

This document provides an overview of statistical process control (SPC). It defines SPC as a statistical method to measure, monitor, and control processes by eliminating special causes of variation. The document discusses the key terms and benefits of SPC. It describes different types of control charts, including variables control charts (e.g., X-bar and R charts) and attributes control charts (e.g., p, np, c, and u charts). Steps for constructing each type of control chart are also outlined. Finally, the document introduces process capability and discusses the Cp and Cpk indices for measuring a process's ability to meet specifications.