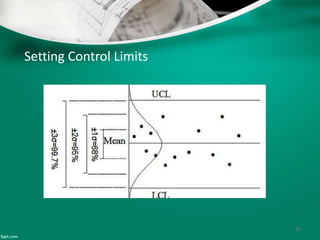

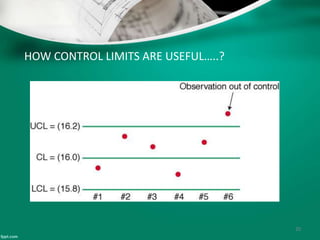

Statistical quality control (SQC) refers to the statistical tools used by quality professionals. SQC was pioneered in the 1920s by Walter Shewhart who developed control charts. Shewhart consulted on applying control charts during WWII. W. Edwards Deming helped introduce SQC methods to American and Japanese industry. SQC includes descriptive statistics, statistical process control (SPC), and acceptance sampling. Descriptive statistics describe quality characteristics while SPC uses control charts to monitor processes and determine if they are in a state of statistical control. Acceptance sampling involves inspecting samples to determine if full lots meet standards.