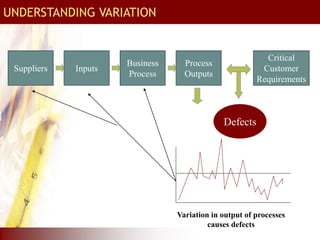

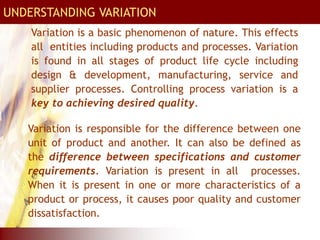

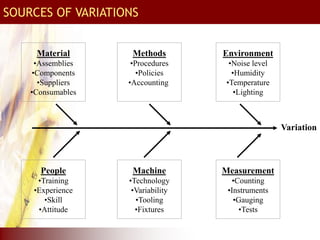

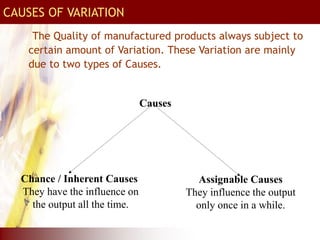

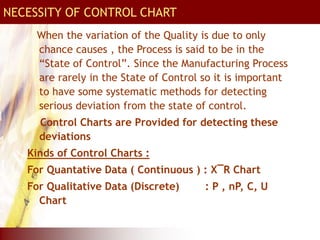

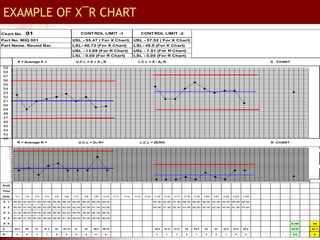

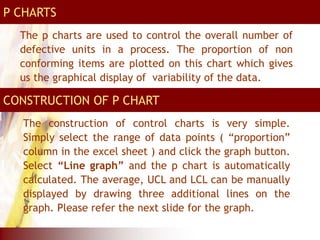

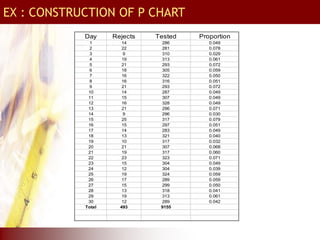

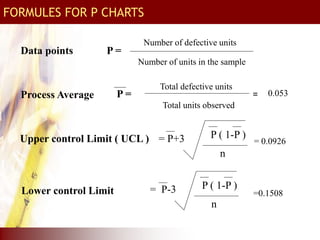

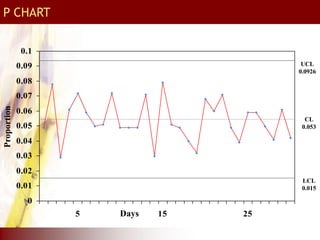

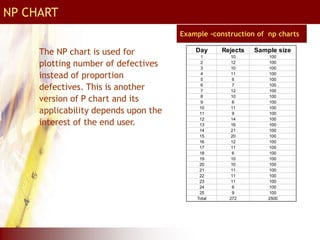

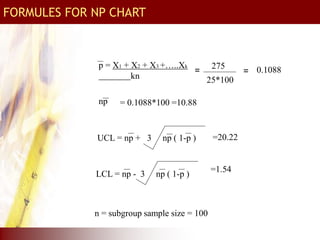

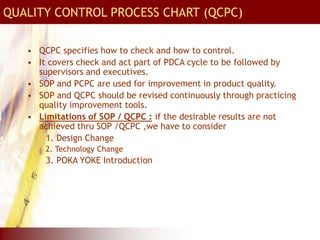

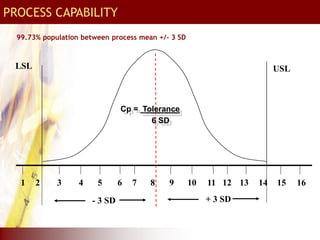

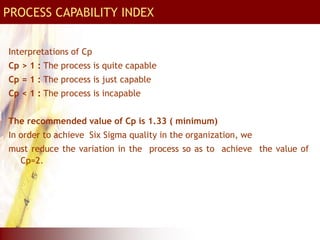

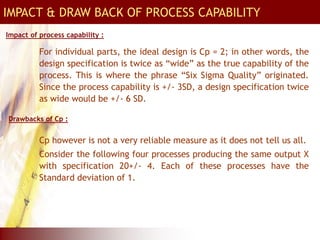

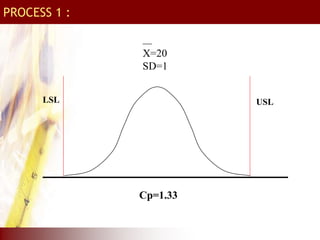

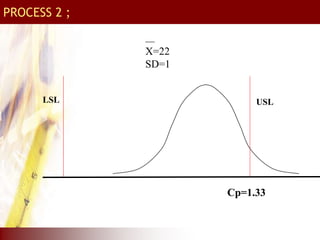

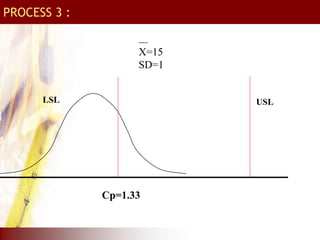

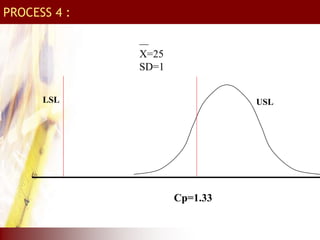

This document provides an overview of total quality management (TQM) concepts for manufacturing, including standard operating procedures (SOP), statistical process control (SPC), process capability indices, and control charts. It discusses how SOPs and quality control process charts are used to standardize operations and check quality. Statistical process control tools like control charts help monitor processes for variation. Process capability indices like Cp and Cpk indicate if a process is capable of meeting specifications. Together, these TQM elements aim to reduce variation and improve quality in manufacturing operations and supply chains.

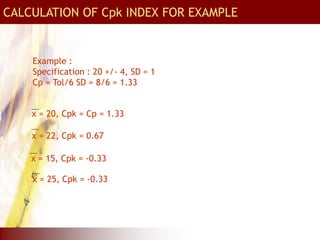

![CALCULATION OF Cpk INDEX

Cpk is a measure of process performance capability

The process performance index Cpk is given by:-

Cpk = Min [ USL - x , x - LSL ]

3SD 3SD

Example :

Specification : 20 +/- 4, SD = 1

Cp = Tolerance/6SD = 8/6 = 1.33](https://image.slidesharecdn.com/tqm-230205141550-18c504e1/85/TQM-15-320.jpg)