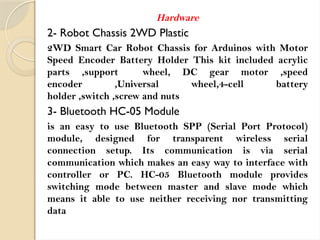

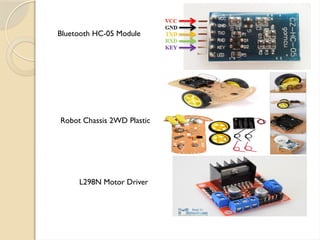

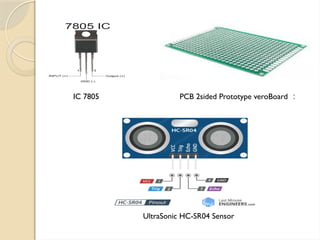

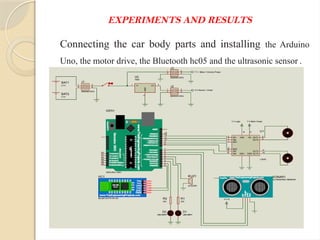

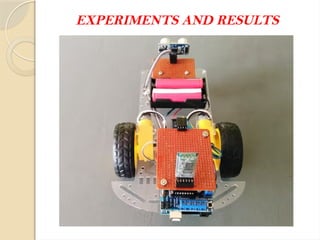

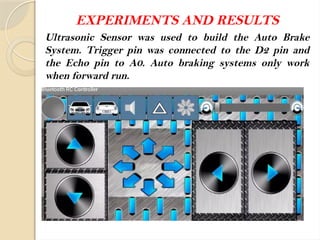

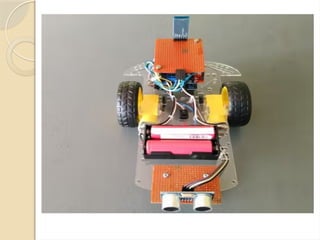

This project presents a system to control the speed and direction of DC motors using an Arduino microcontroller, an Android application, and Bluetooth technology. The approach utilizes pulse width modulation (PWM) for speed regulation, enabling control via a smartphone interface for applications such as robotic vehicles and industrial machinery. The system enhances operational efficiency by minimizing manual controls and allowing for wireless communication, demonstrating significant potential for agricultural and industrial applications.