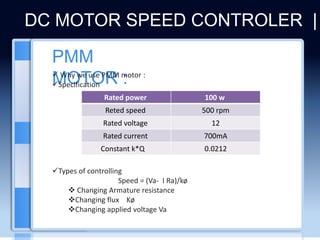

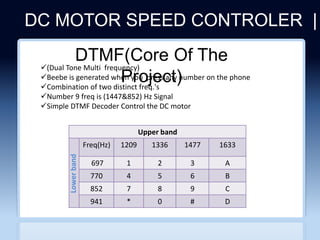

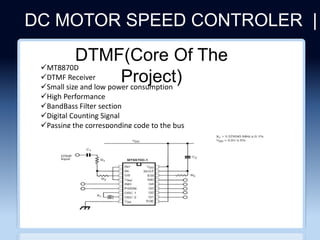

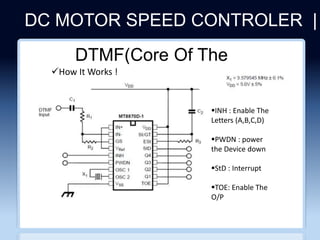

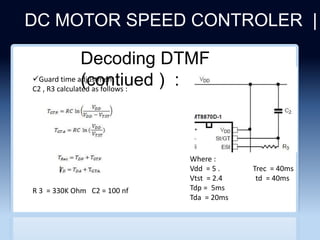

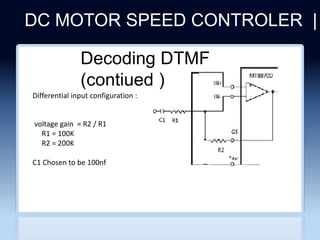

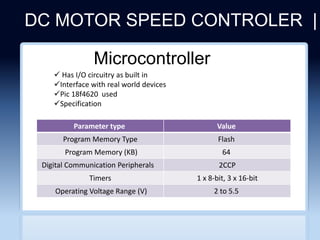

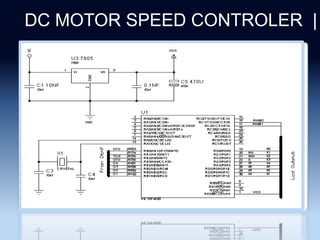

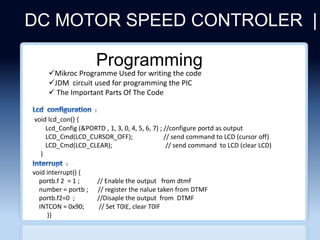

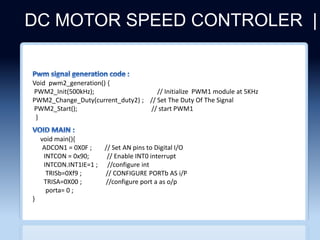

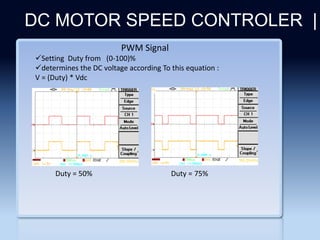

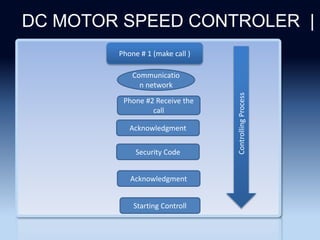

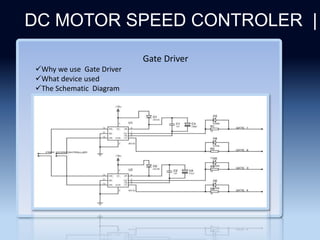

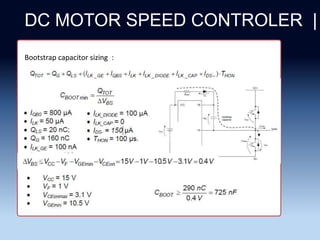

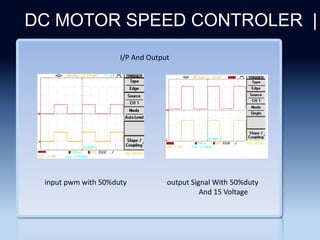

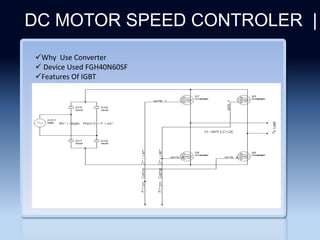

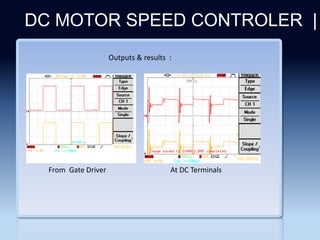

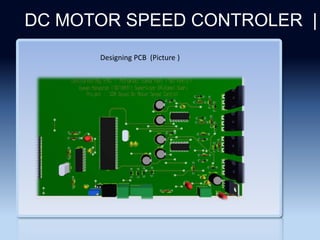

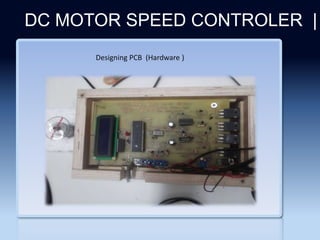

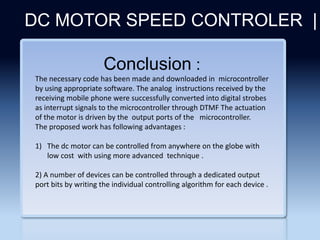

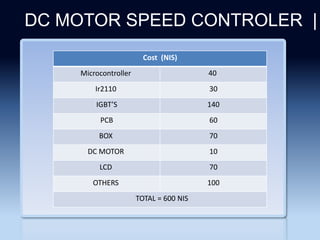

The document describes a DC motor speed controller project that uses DTMF signals from a phone to control the speed of a DC motor. A PIC microcontroller receives DTMF signals from a phone and generates PWM signals to control an IGBT and drive the motor speed. The system was designed and a PCB was made to test the speed control of a 100W DC motor from a phone remotely. Future work may include improving the design to control larger motors and monitor devices remotely in homes.