This document discusses measurement techniques and instruments. It covers the basic components, classifications, functions, and errors of measurement instruments. The key points are:

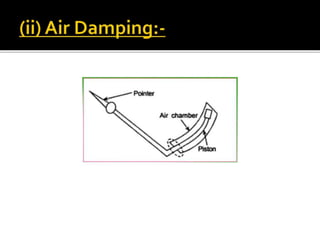

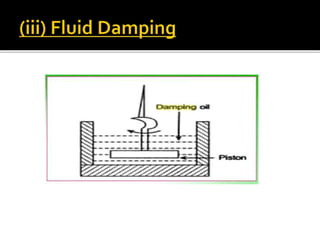

- Measurement instruments have components for deflection, control, and damping of the pointer. Deflection indicates the measured quantity, control opposes deflection, and damping reduces oscillations.

- Instruments can be classified as analog or digital, absolute or secondary. Accuracy depends on design, materials, and errors like systematic, random, and environmental errors.

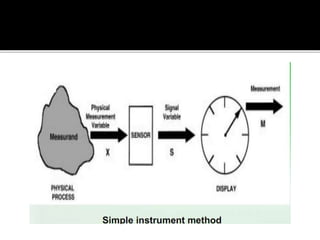

- Measurements involve comparing an unknown quantity to a standard and expressing the result numerically. Direct comparison is used when possible, otherwise indirect methods are used. Proper standards and methods are required for meaningful results.

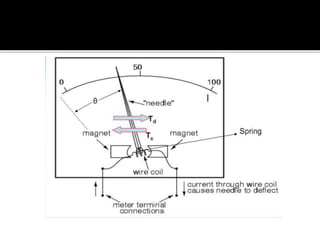

![ Td = G.I

[ where G is depends Flux density, number

of turns are the moving coil]

Tc = K.θ

[ where K is the spring constant which

depends upon the material and dimensions of

the spring ]](https://image.slidesharecdn.com/eee404-190922161704/85/ELECTRICAL-AND-ELECTRONICS-MEASUREMENT-40-320.jpg)