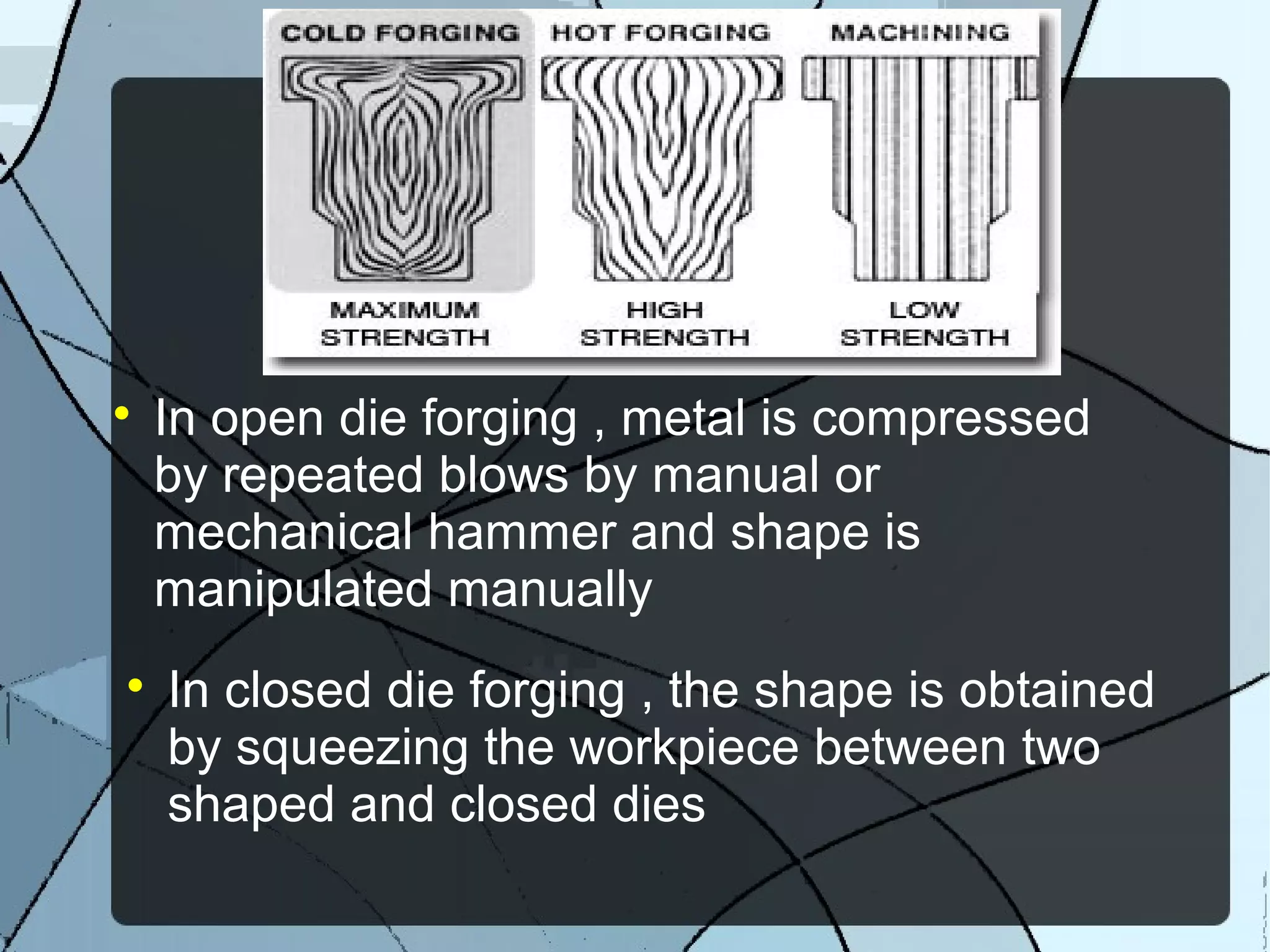

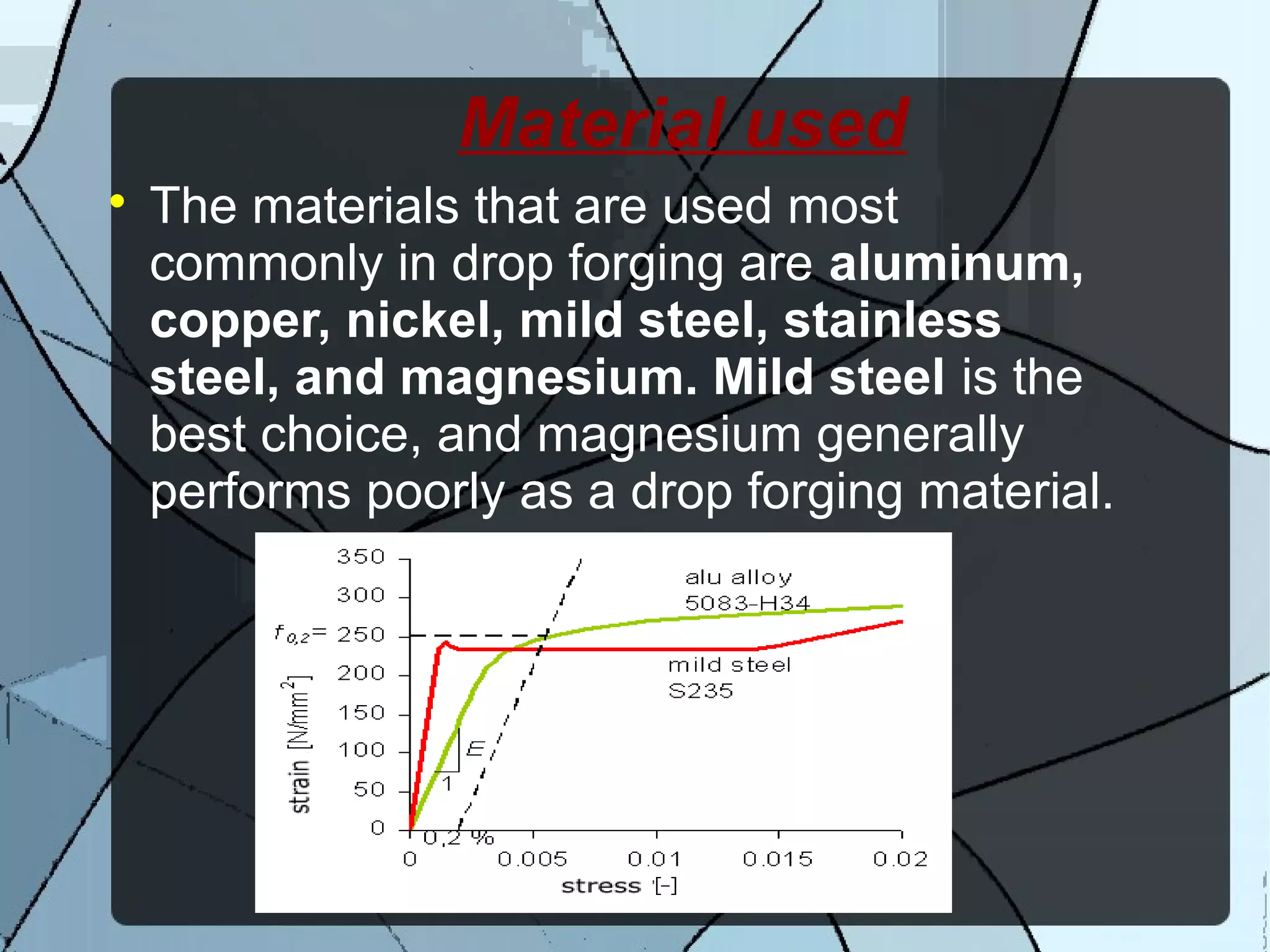

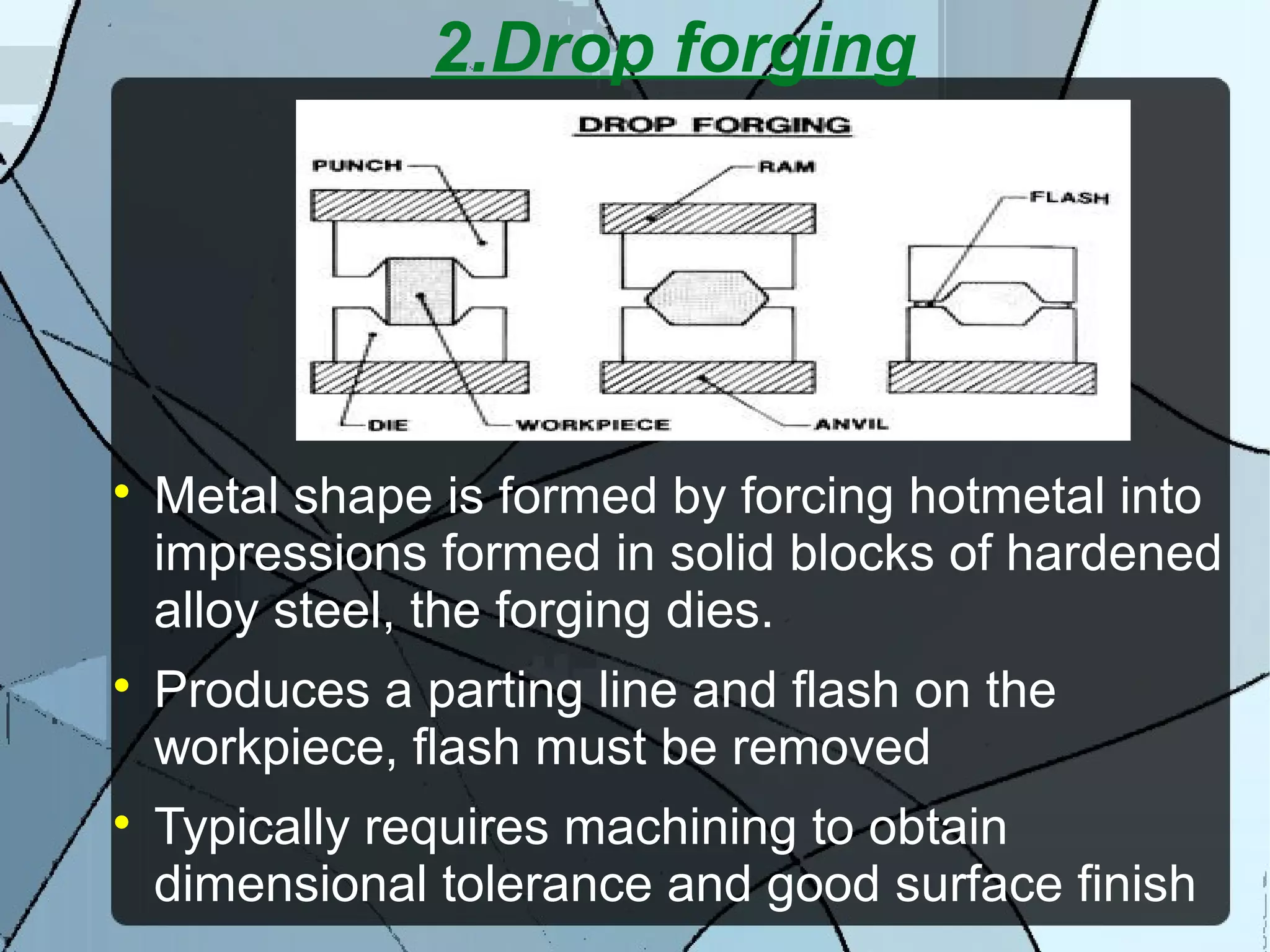

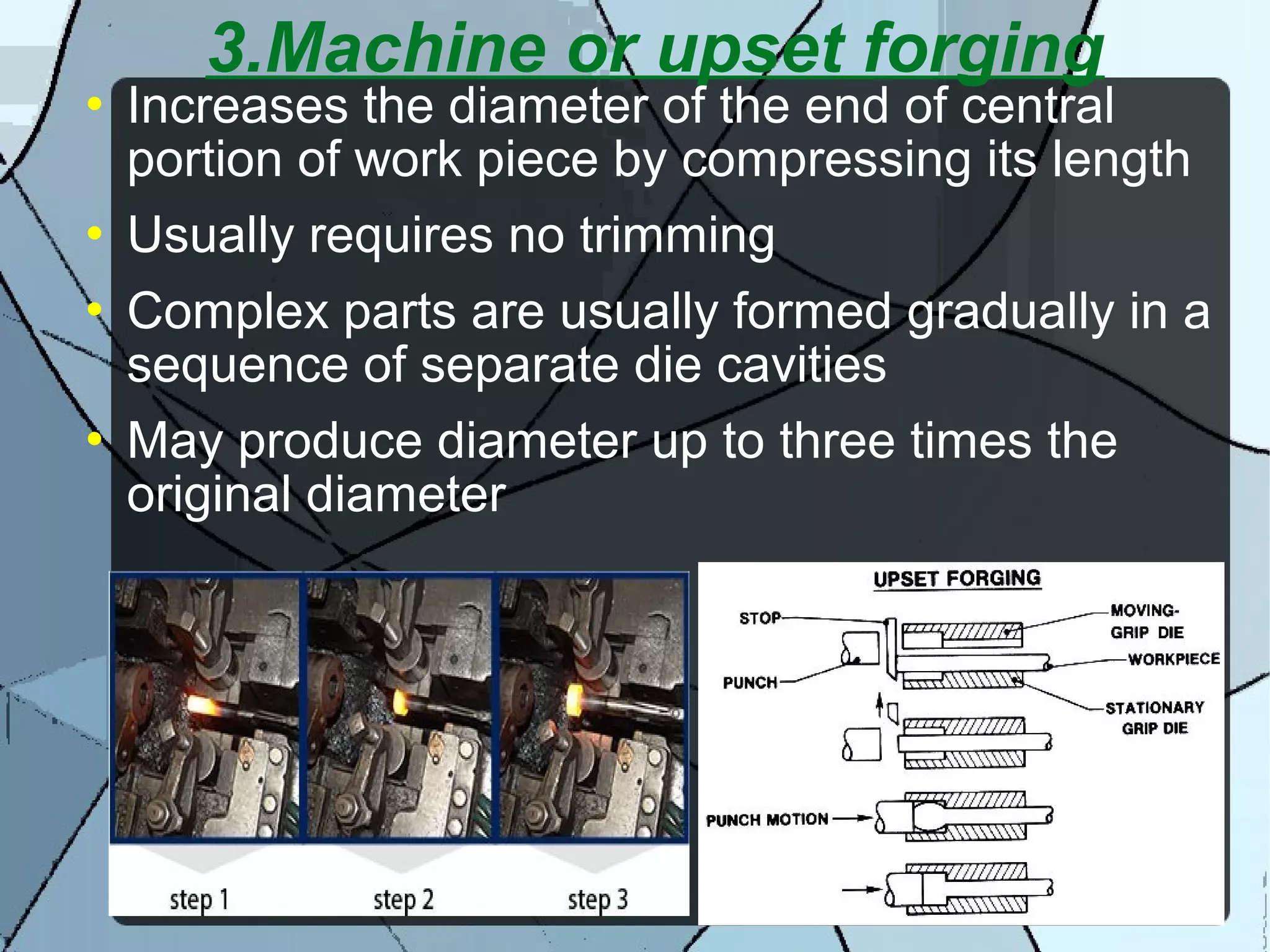

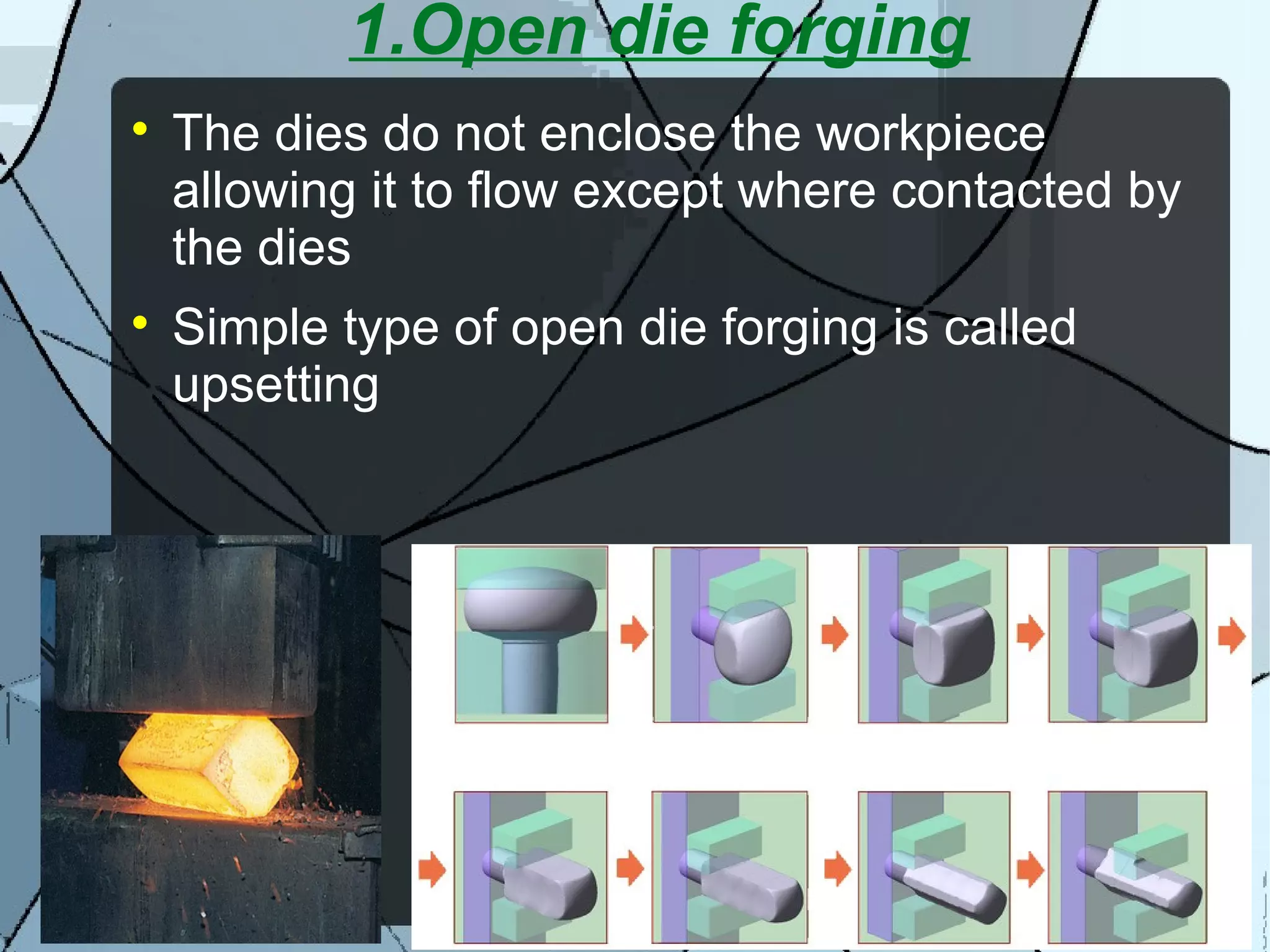

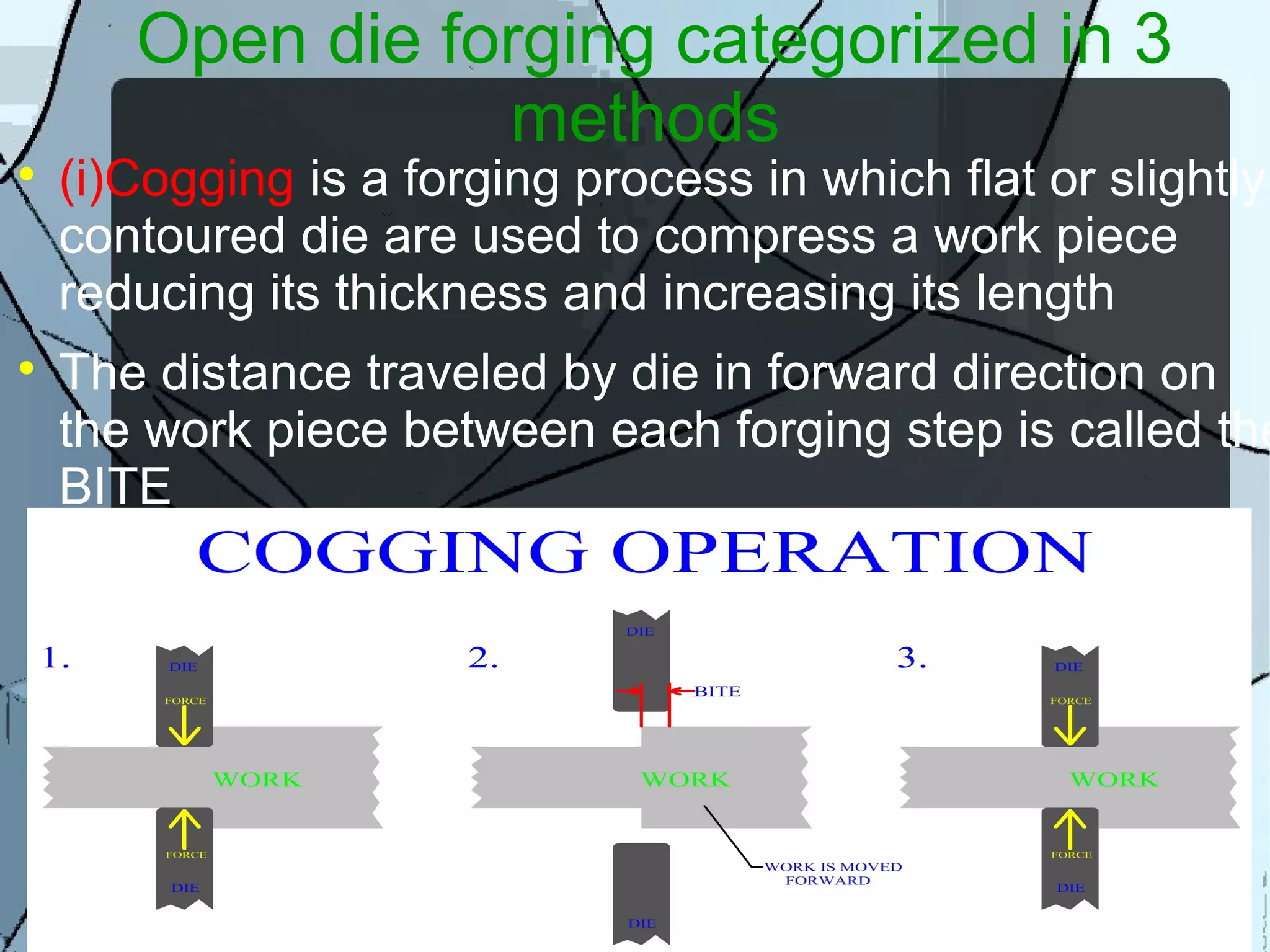

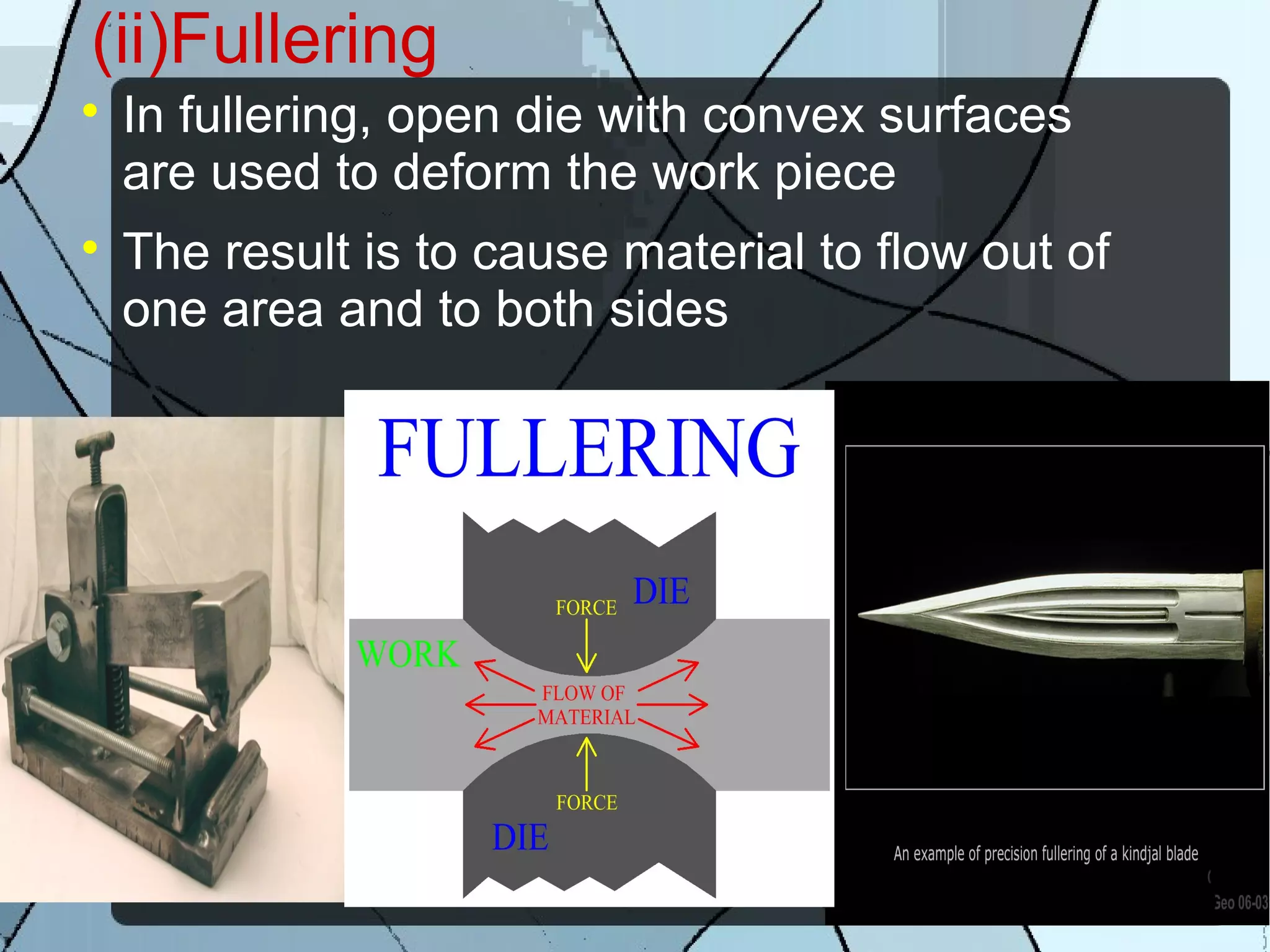

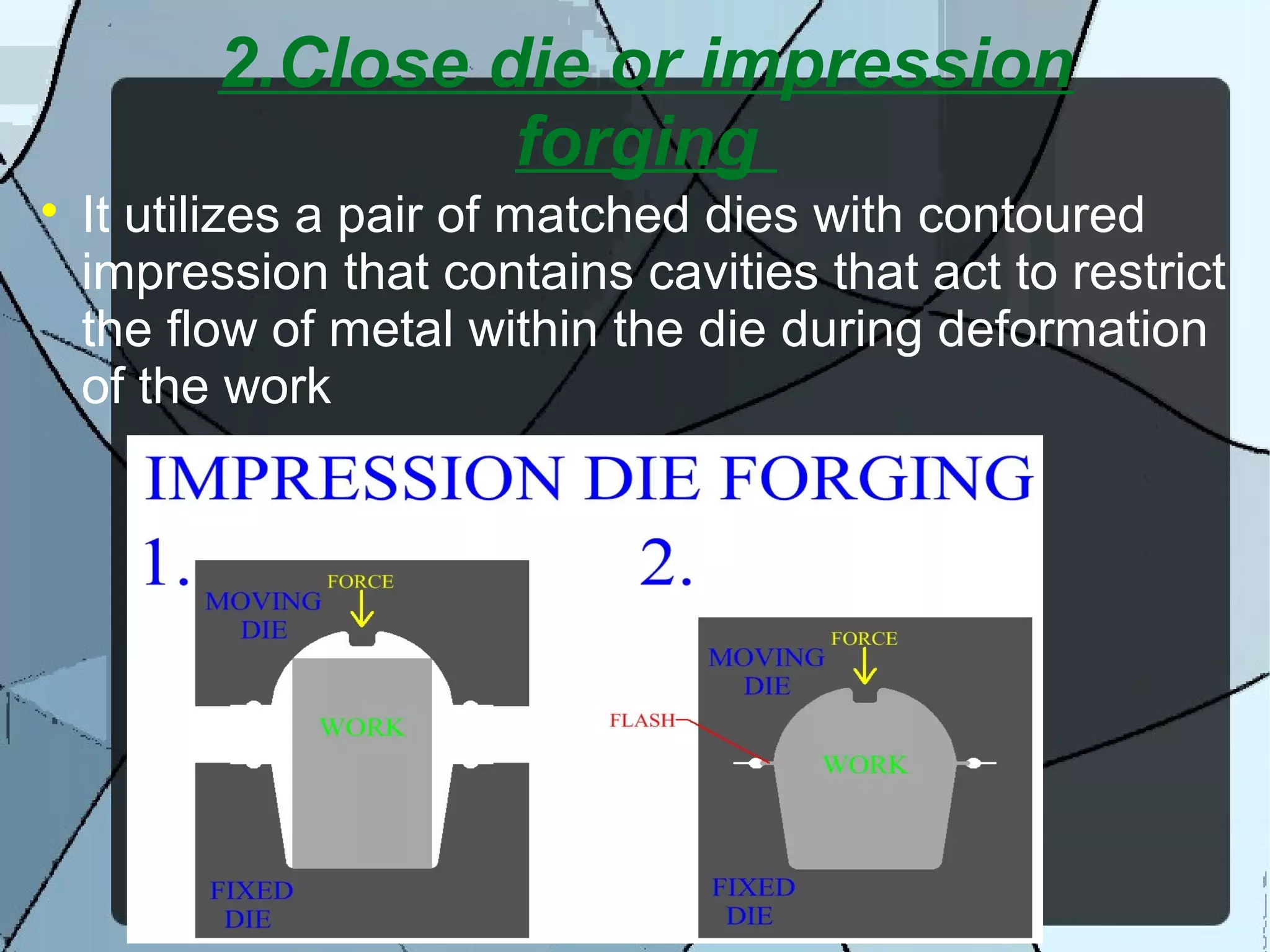

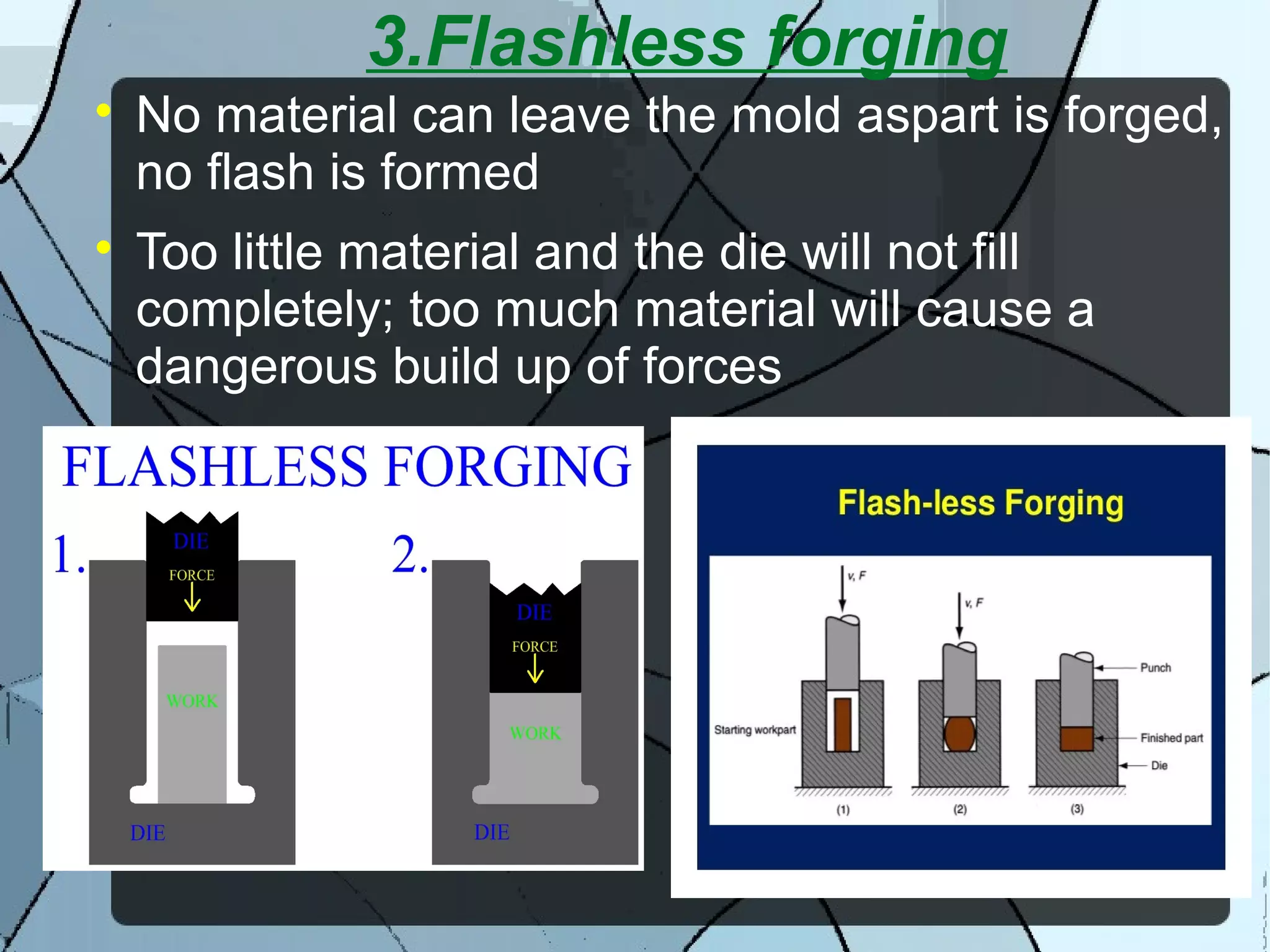

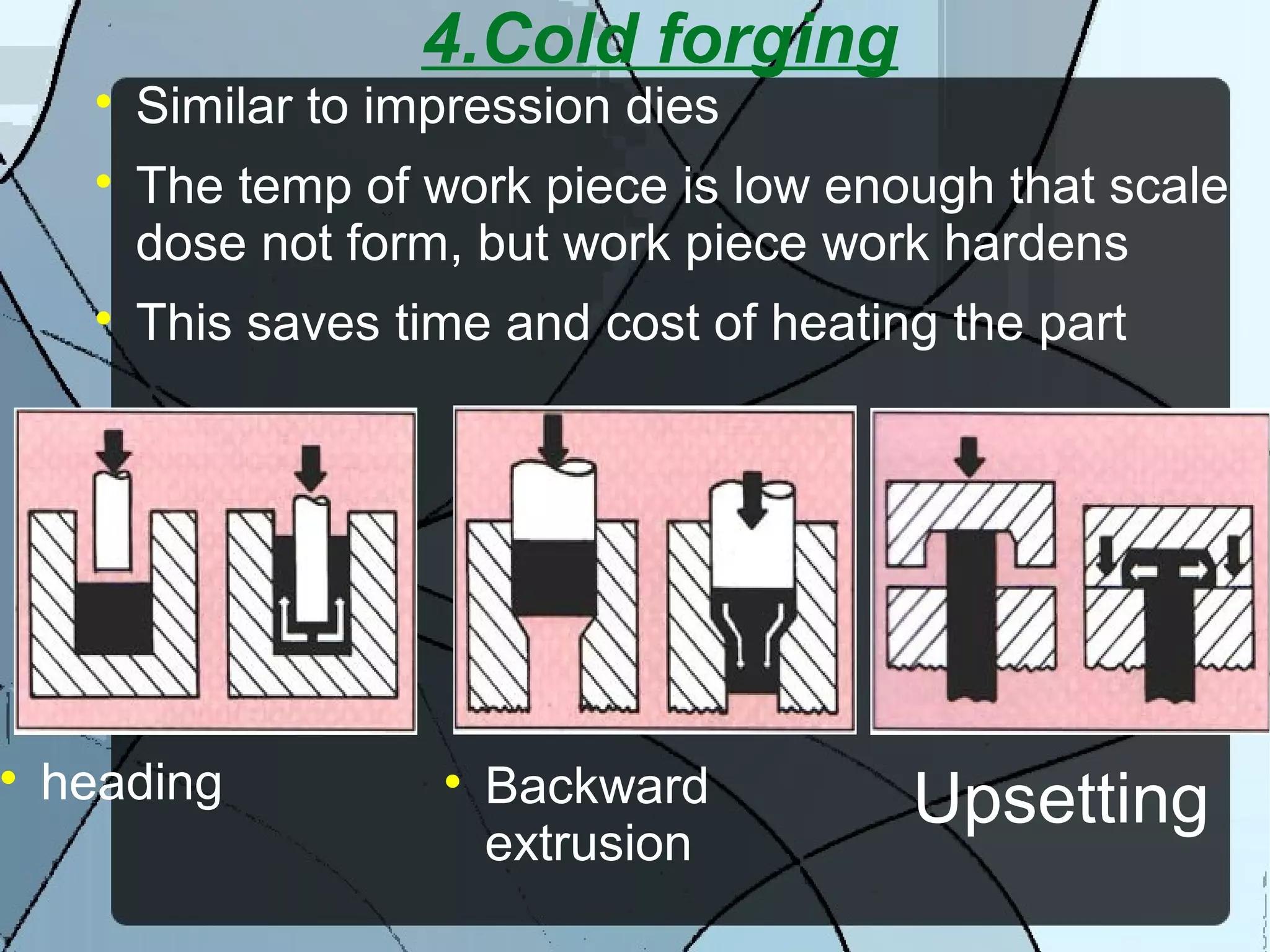

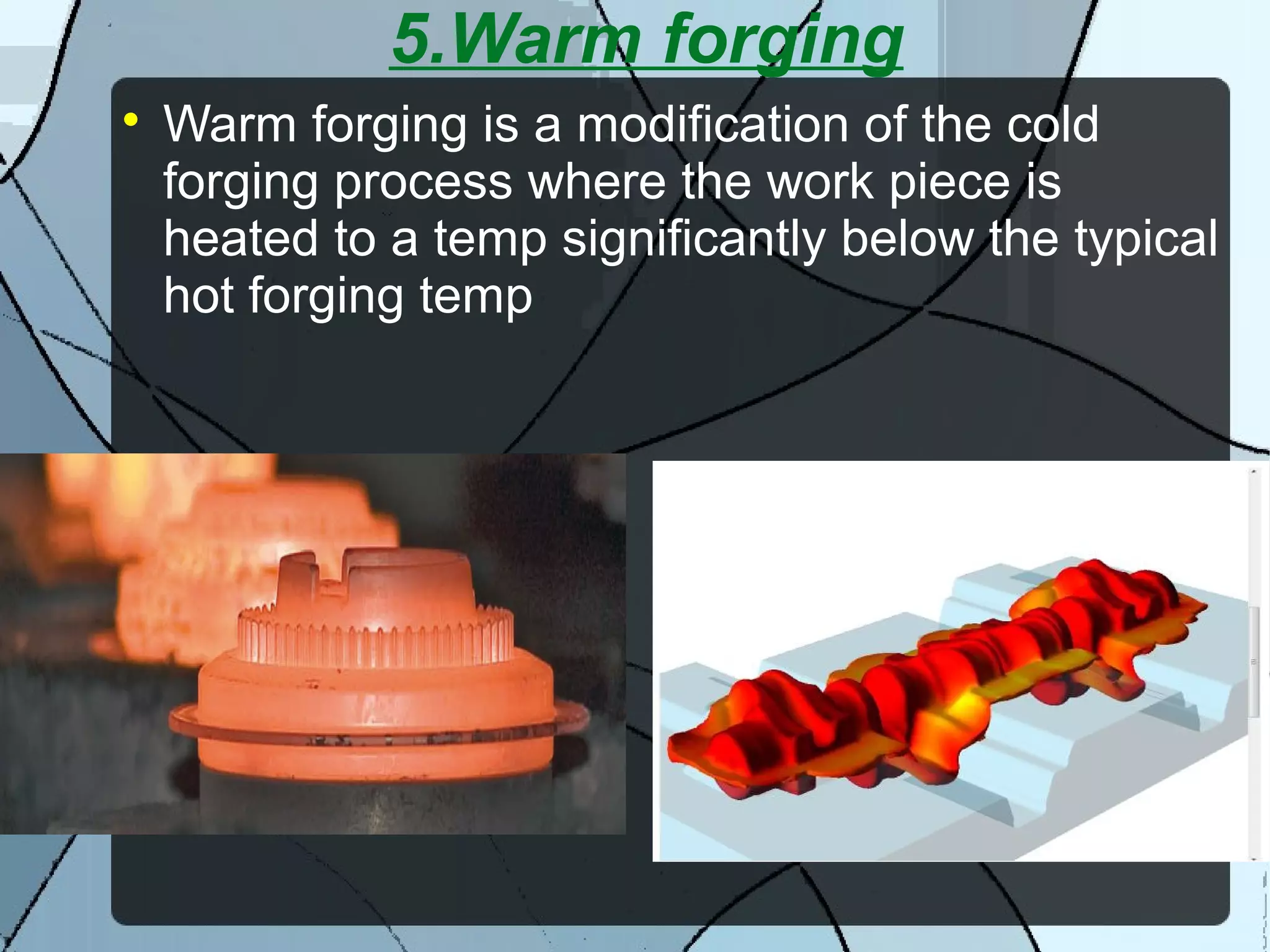

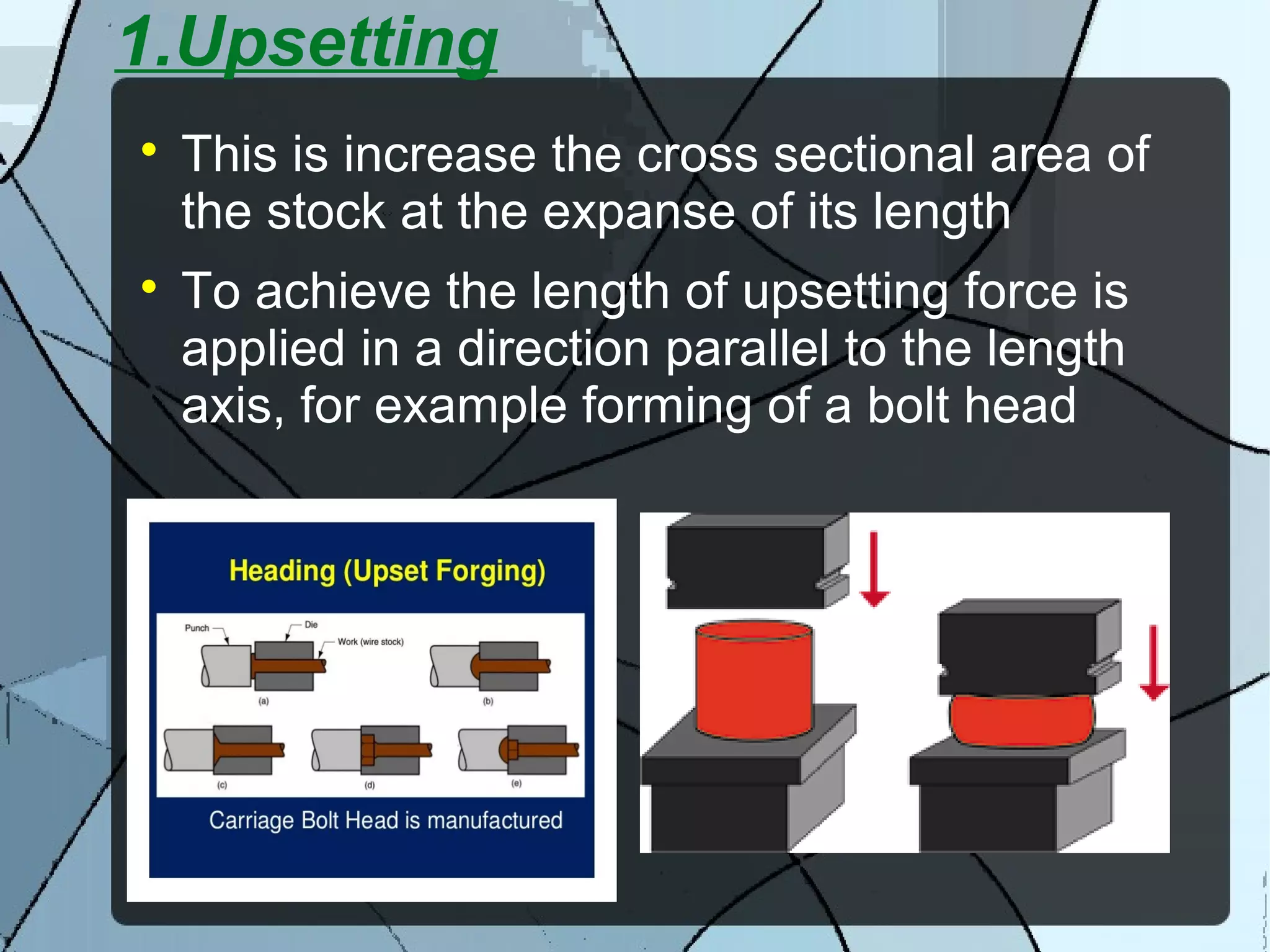

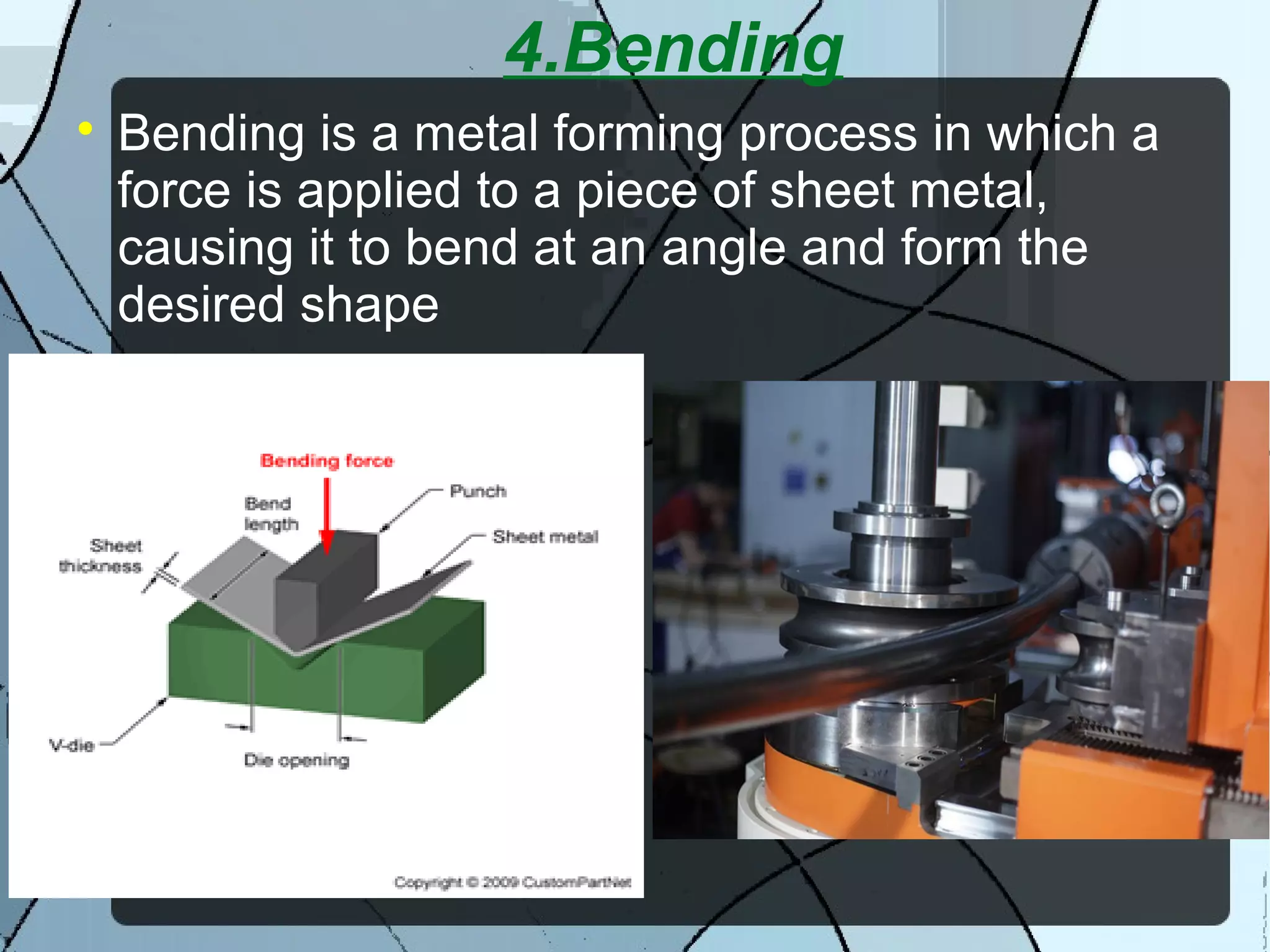

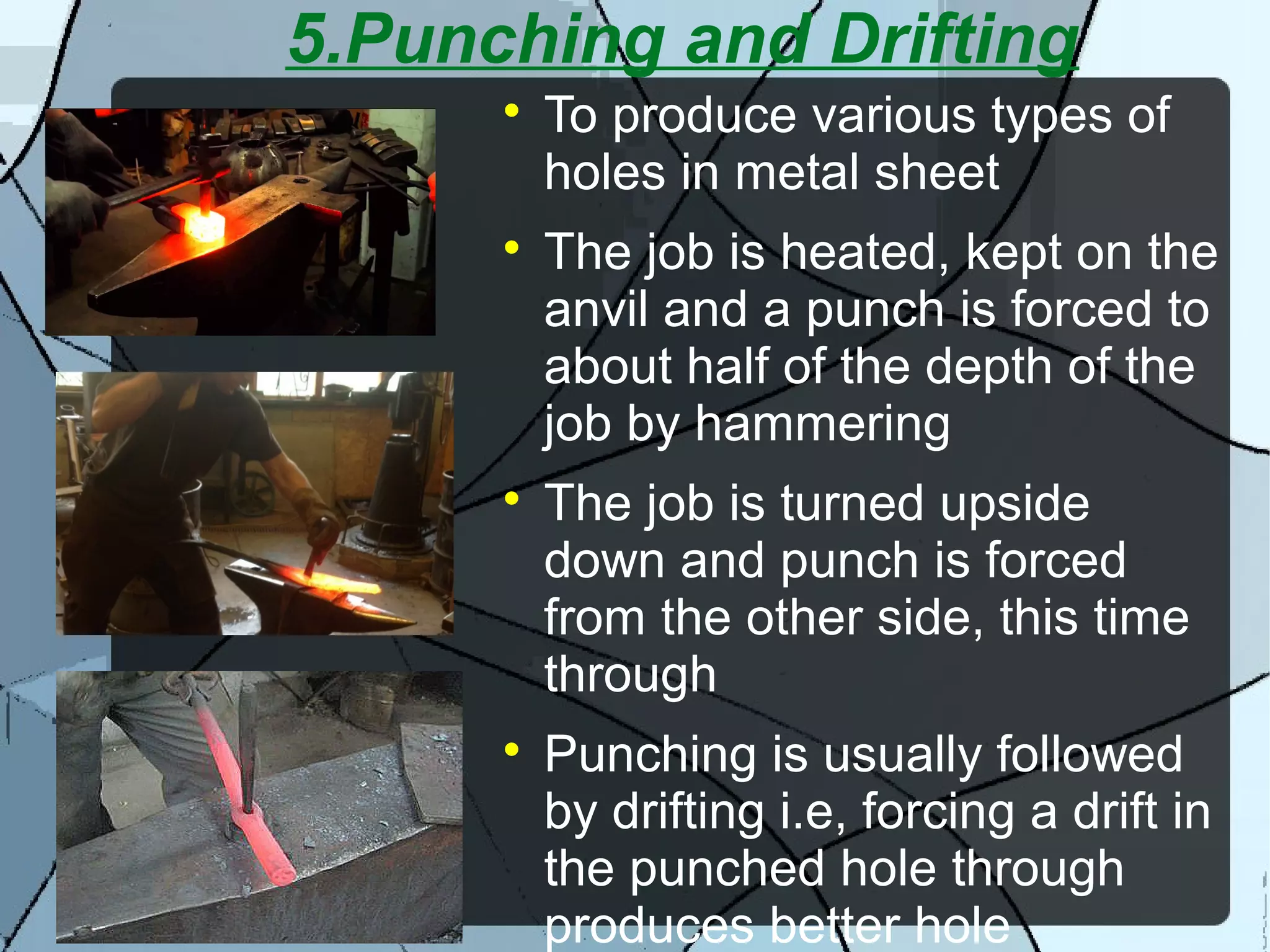

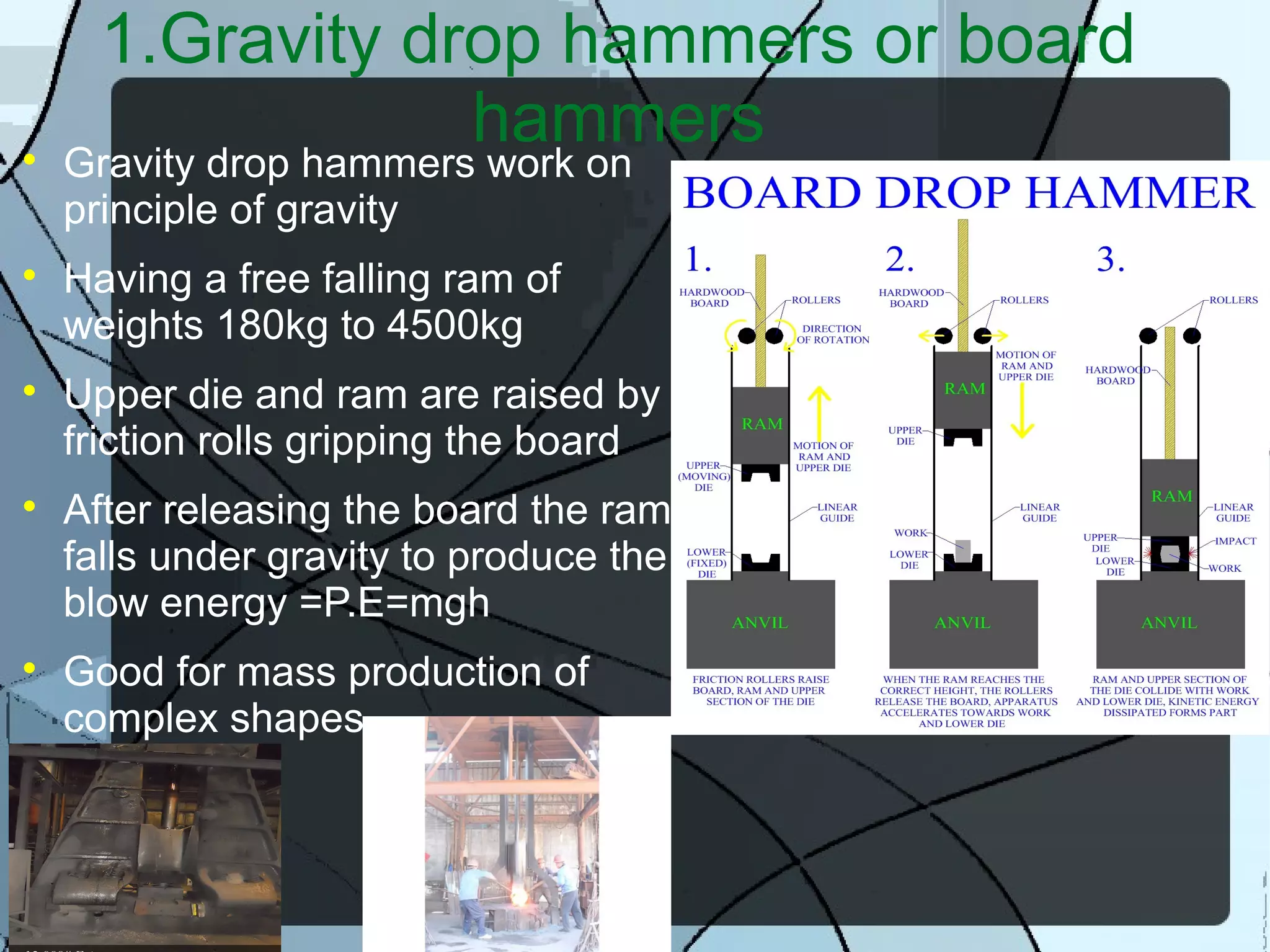

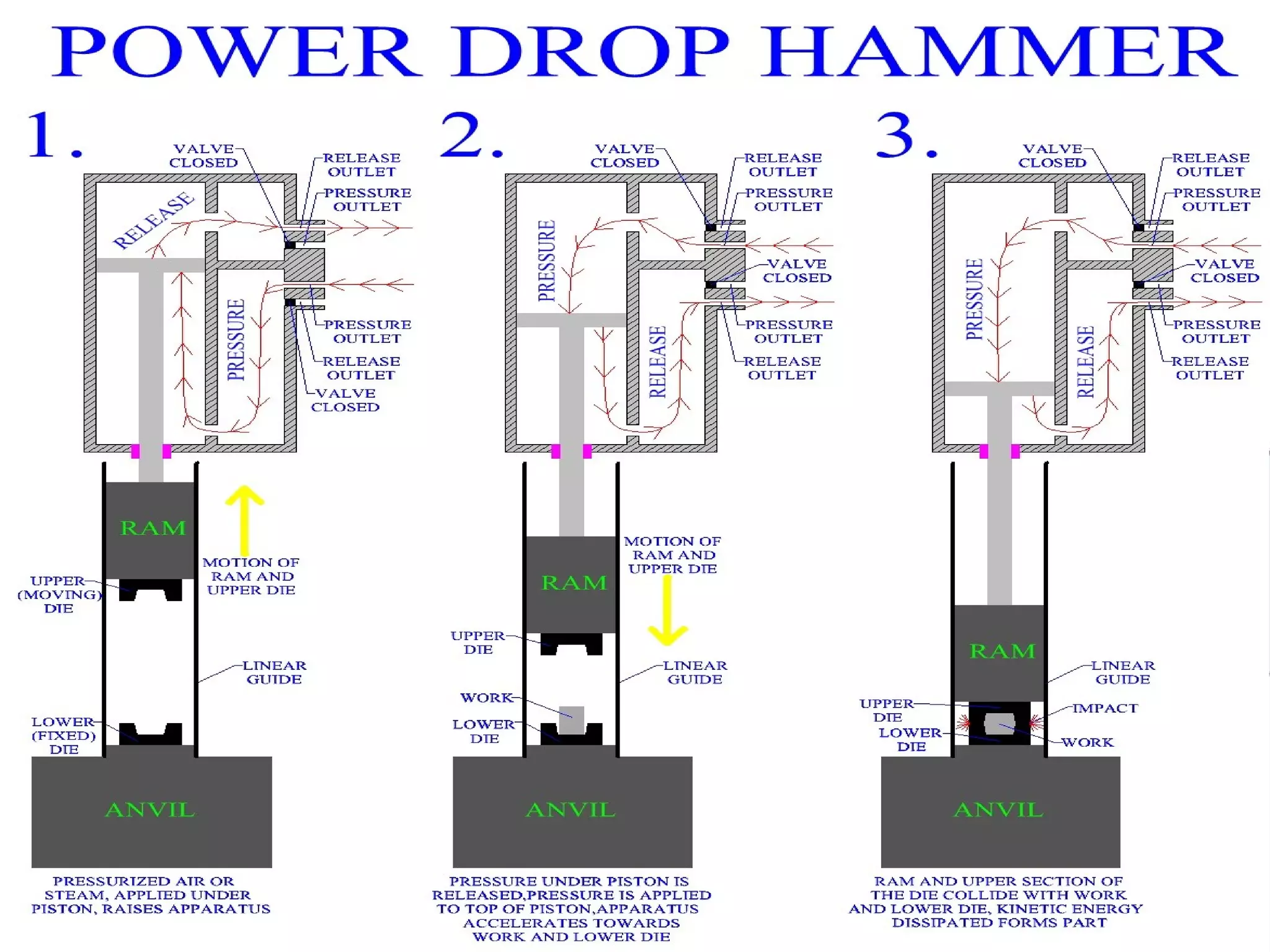

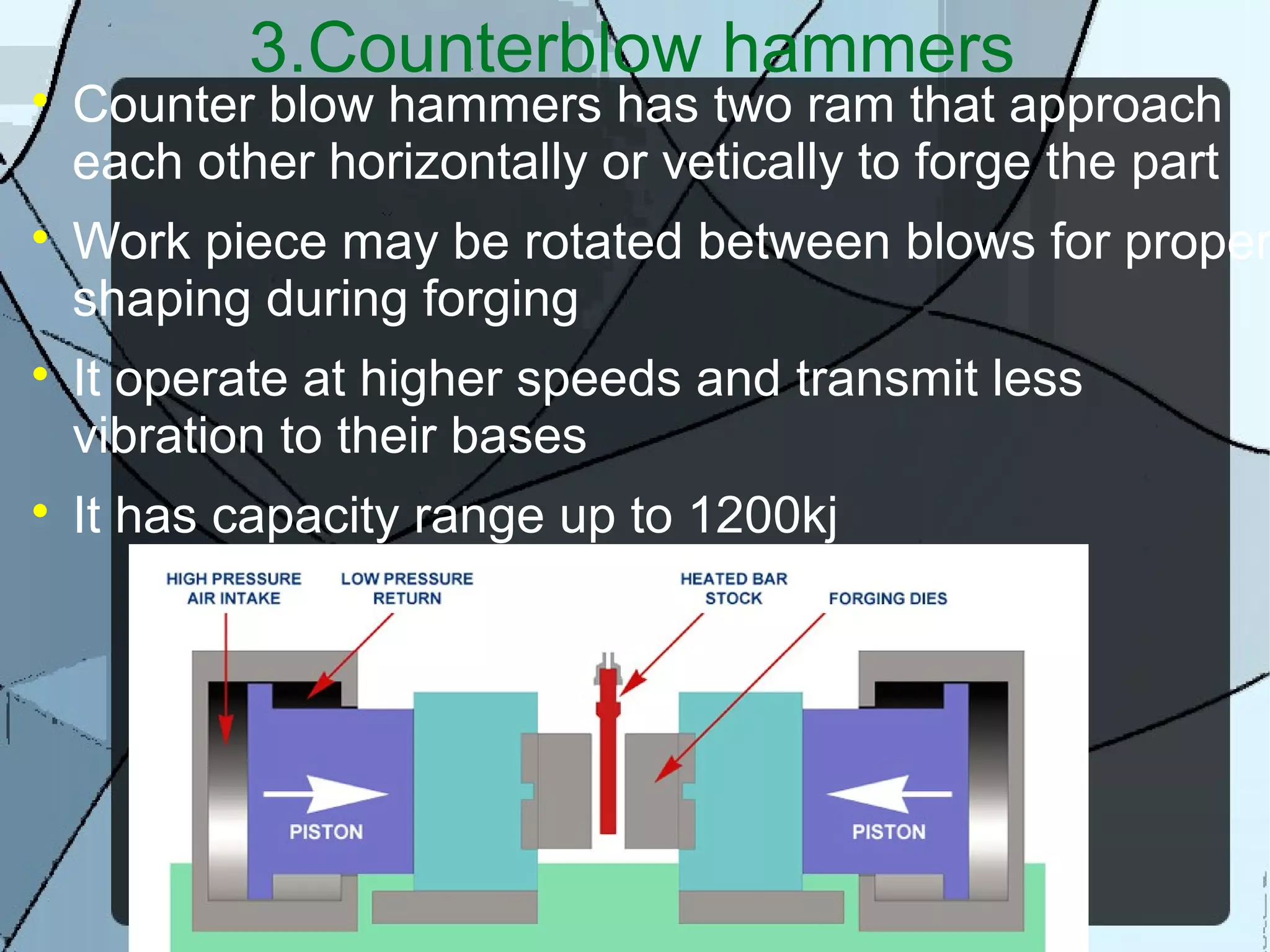

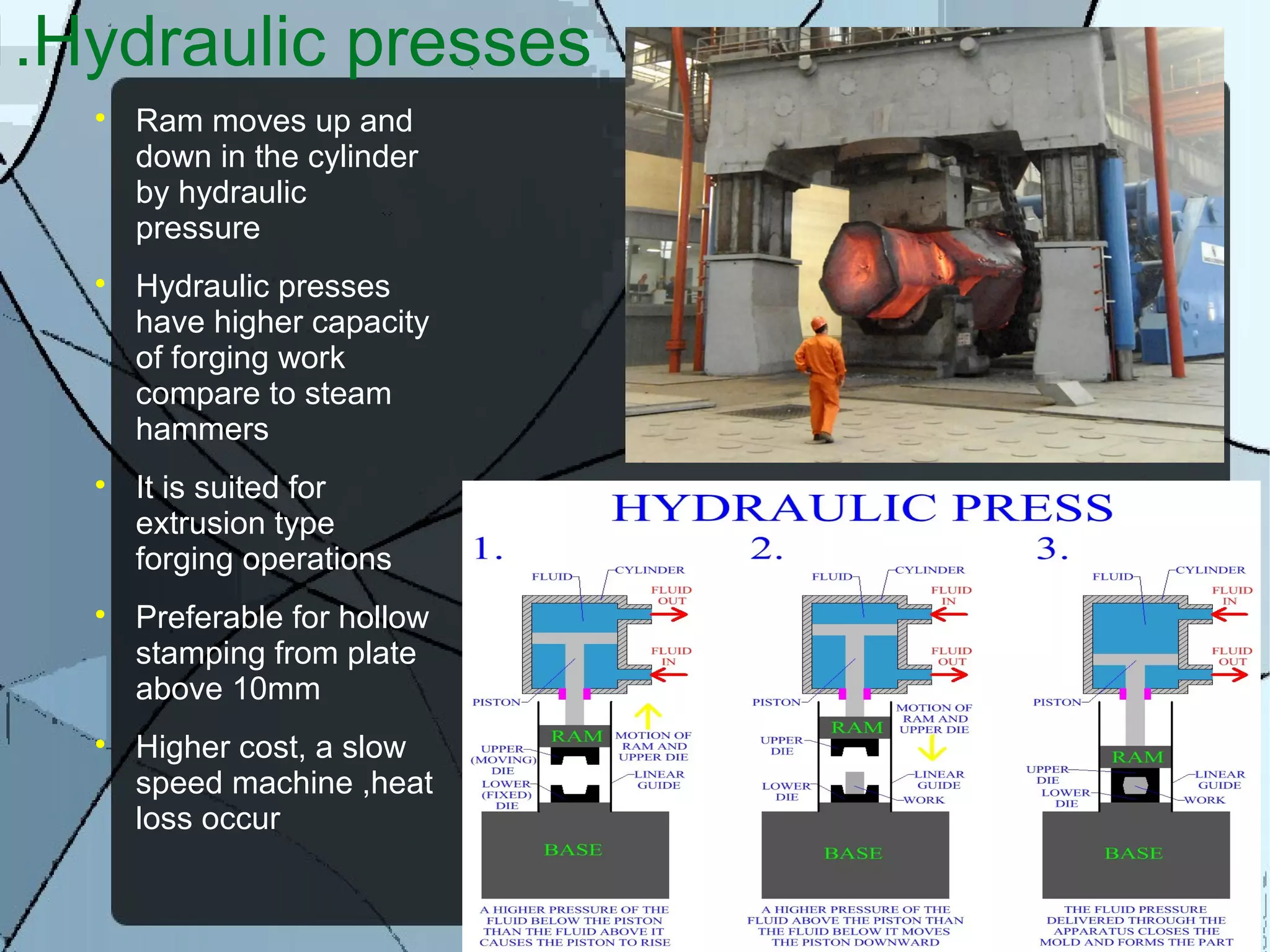

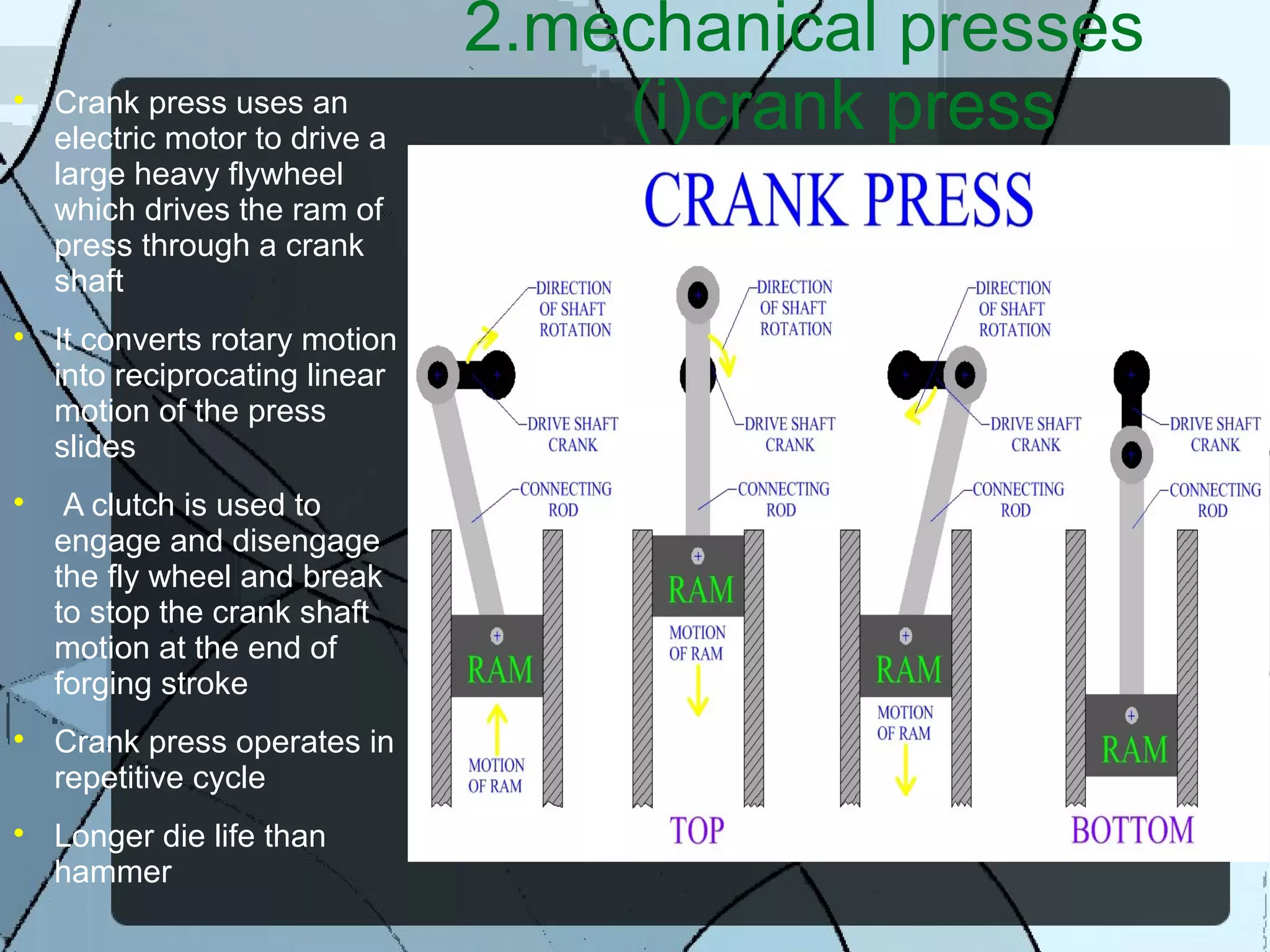

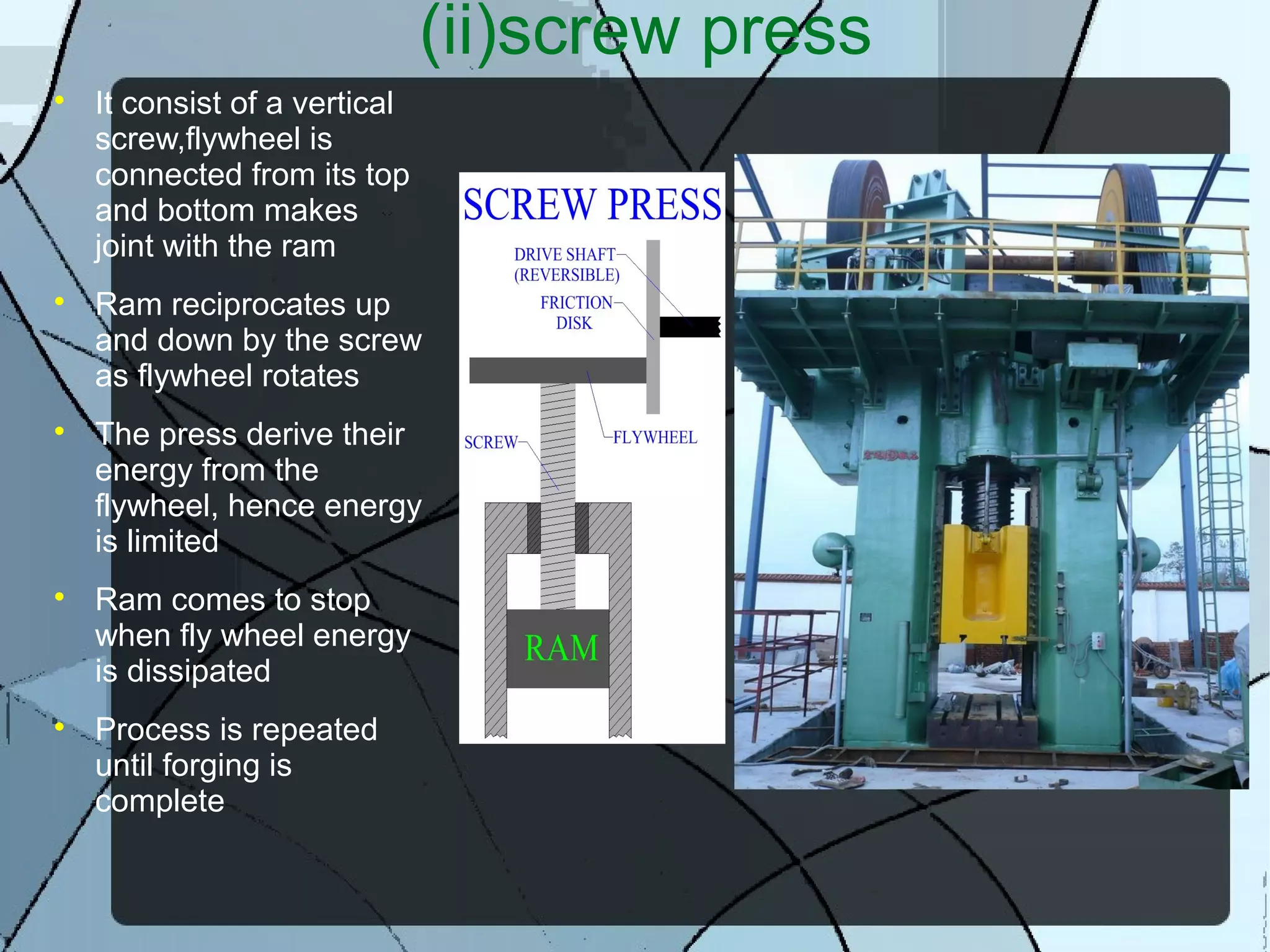

The document discusses forging, a process of shaping metal through plastic deformation between dies, emphasizing its benefits such as improved mechanical properties and absence of internal voids. It details various types of forging (e.g., open die, closed die, and cold forging) and operations (like upsetting, bending, and punching), and the machinery used, including different hammers and presses. Additionally, it outlines potential forging defects and their causes, underscoring the importance of proper design and material distribution.