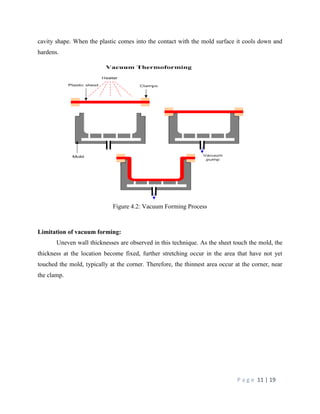

The document outlines the importance of food packaging as a coordinated system for delivering safe food products and highlights the role of various polymers in packaging materials. It discusses biodegradable packaging's rise due to consumer demand and environmental concerns, detailing different types of food packaging polymers, methods of synthesis, processing, degradation, and practical applications. The text illustrates advances in food packaging technology aimed at improving food quality and safety while also addressing sustainability.