The document discusses material characterization methods including X-ray diffraction (XRD) and scanning electron microscopy (SEM) used to analyze metallic materials. XRD identifies the composition and crystalline structure of materials while SEM provides high-resolution images of atomic arrangements and fractured surfaces. The document also proposes additional techniques like Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) for advanced material analysis.

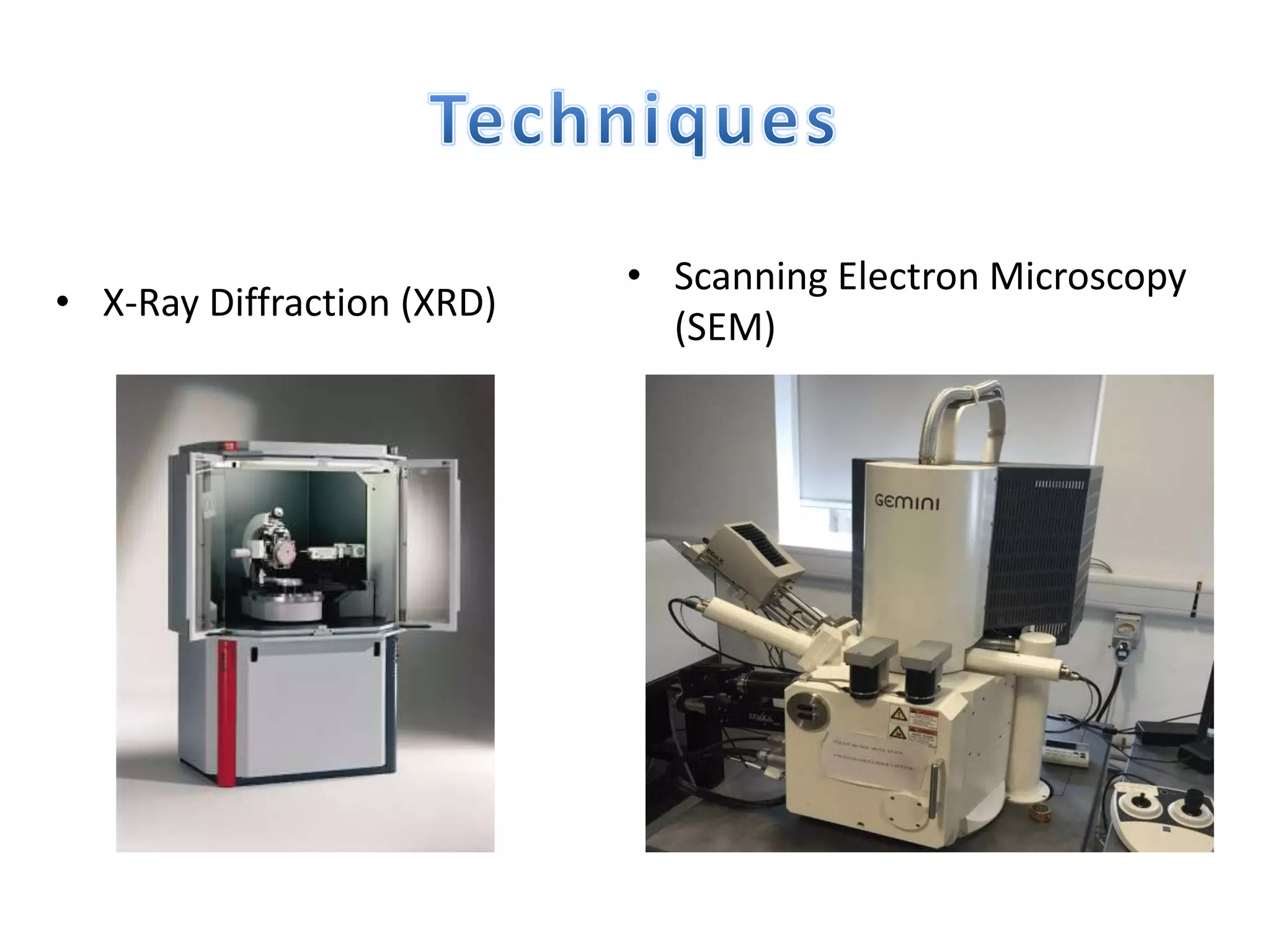

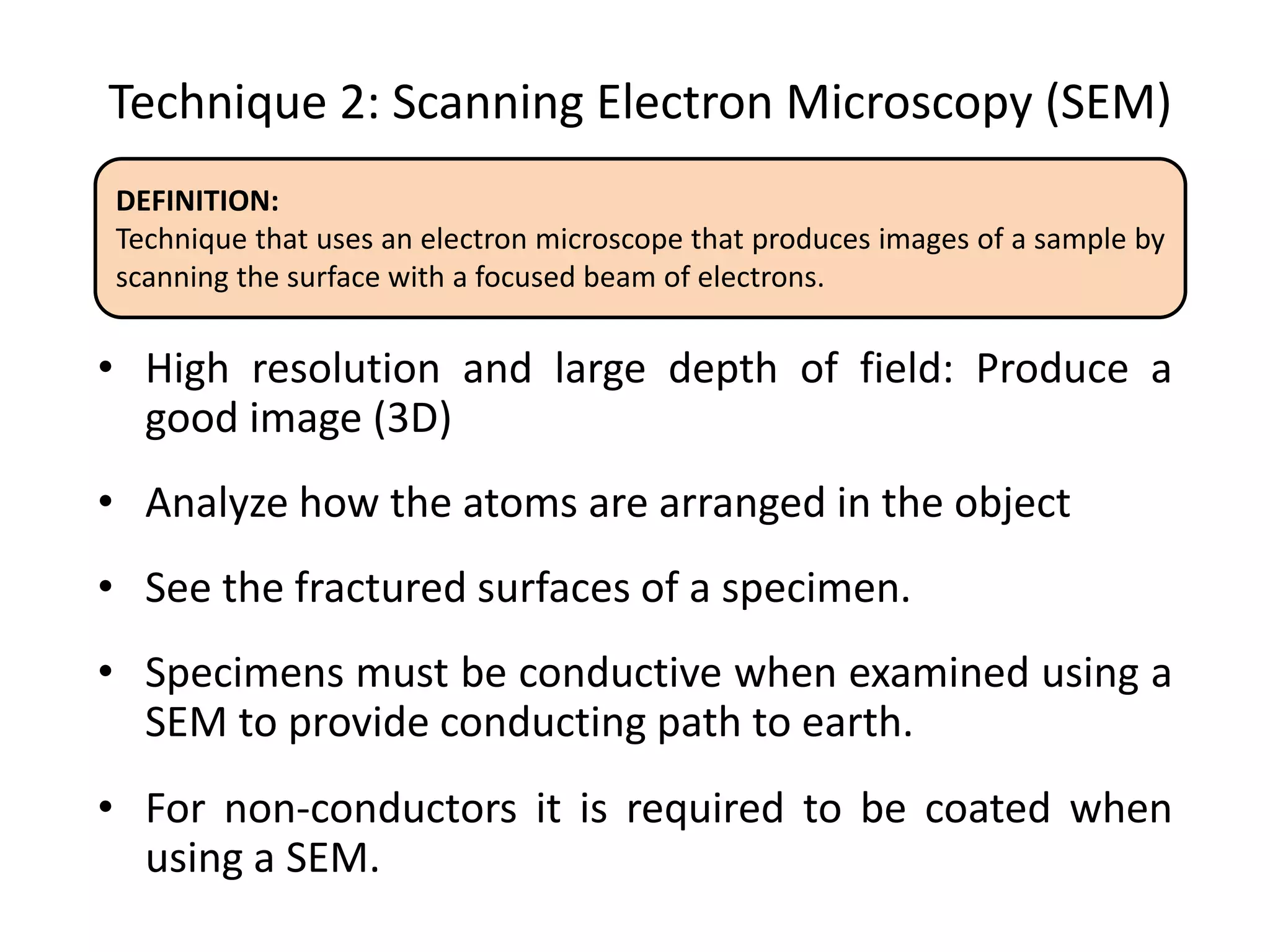

![Results : XRD

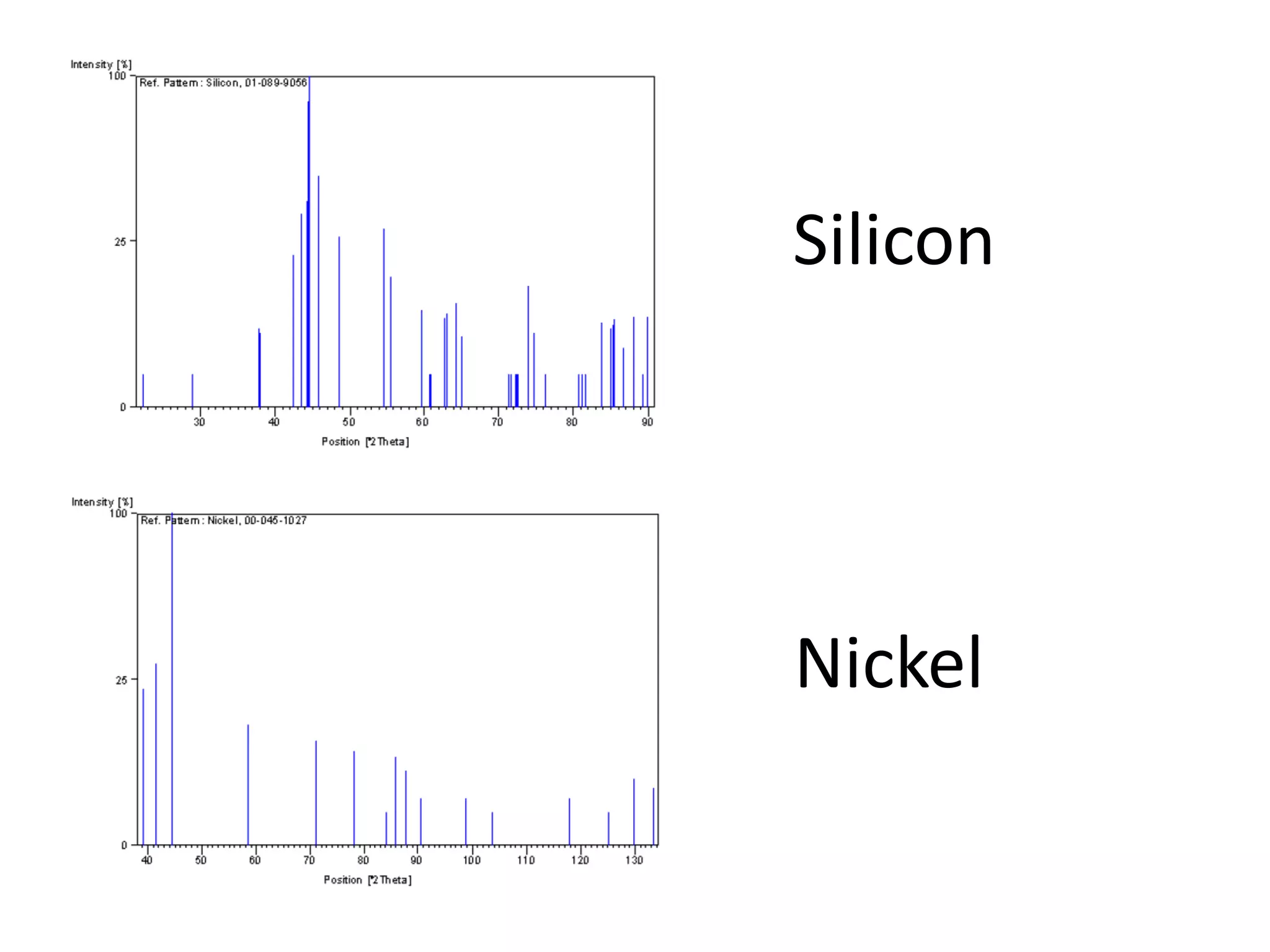

• The composition is identified by comparing the XRD pattern to the

library of known patterns.

• Aluminum, Silicon and Nickel.

Position [°2Theta] (Copper (Cu))

20 30 40 50 60 70 80

Counts

0

1000

2000

3000

4000

Al;Si

Al;Si;Ni

Al

Al;Ni

Al

Carron](https://image.slidesharecdn.com/mcpresentation-180508132453/75/Material-Characterization-of-Tensile-Bar-Slides-7-2048.jpg)

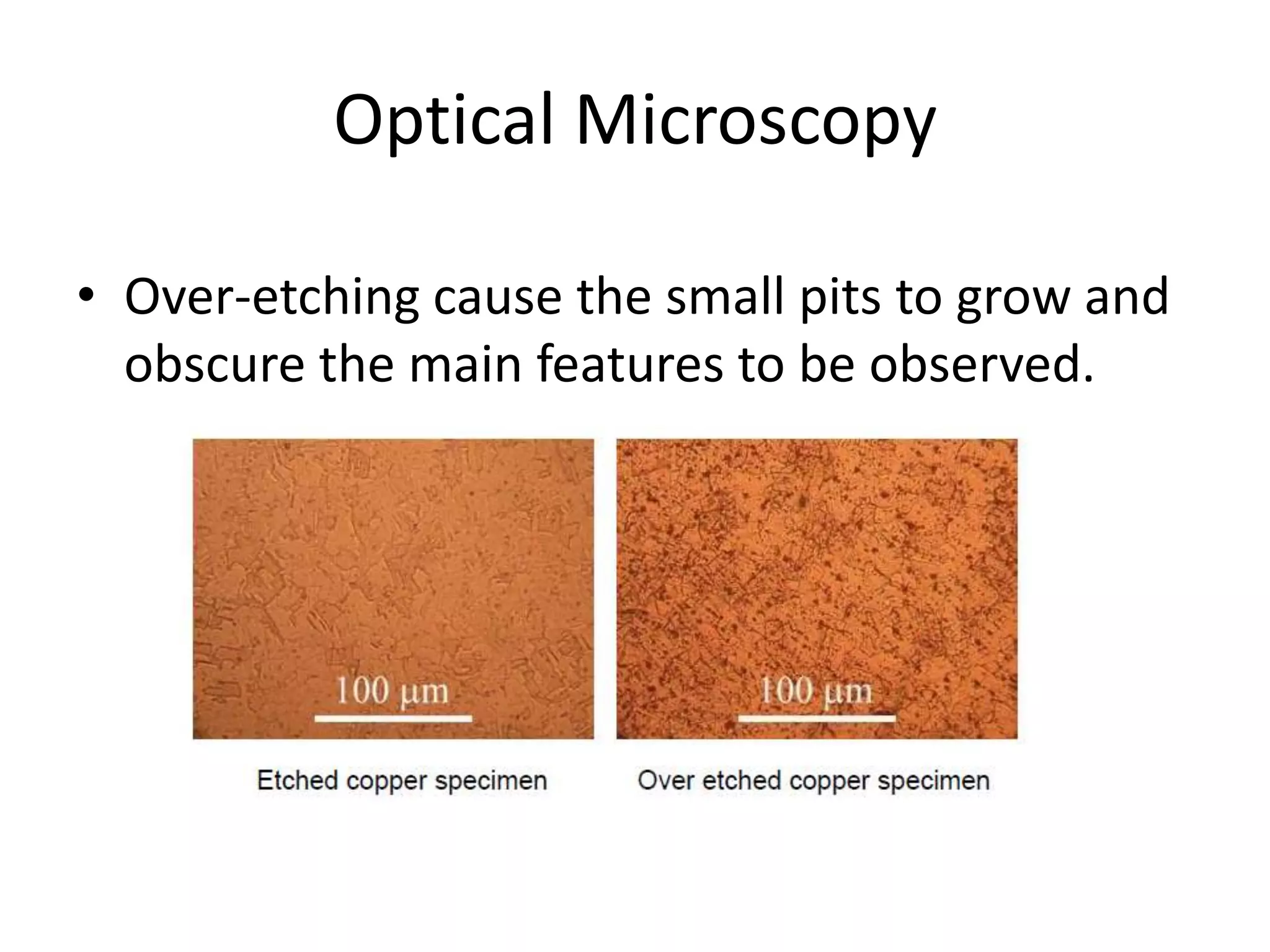

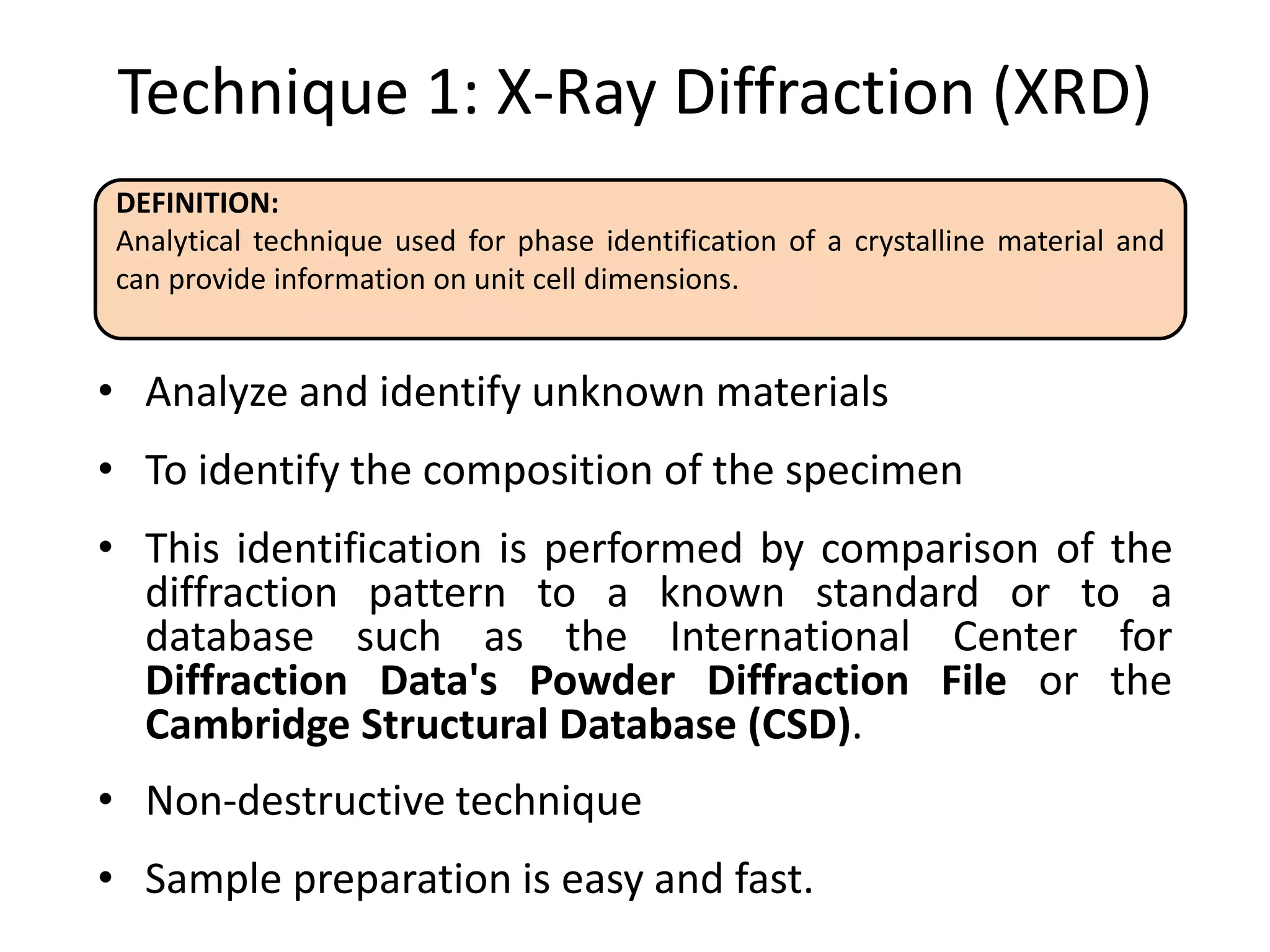

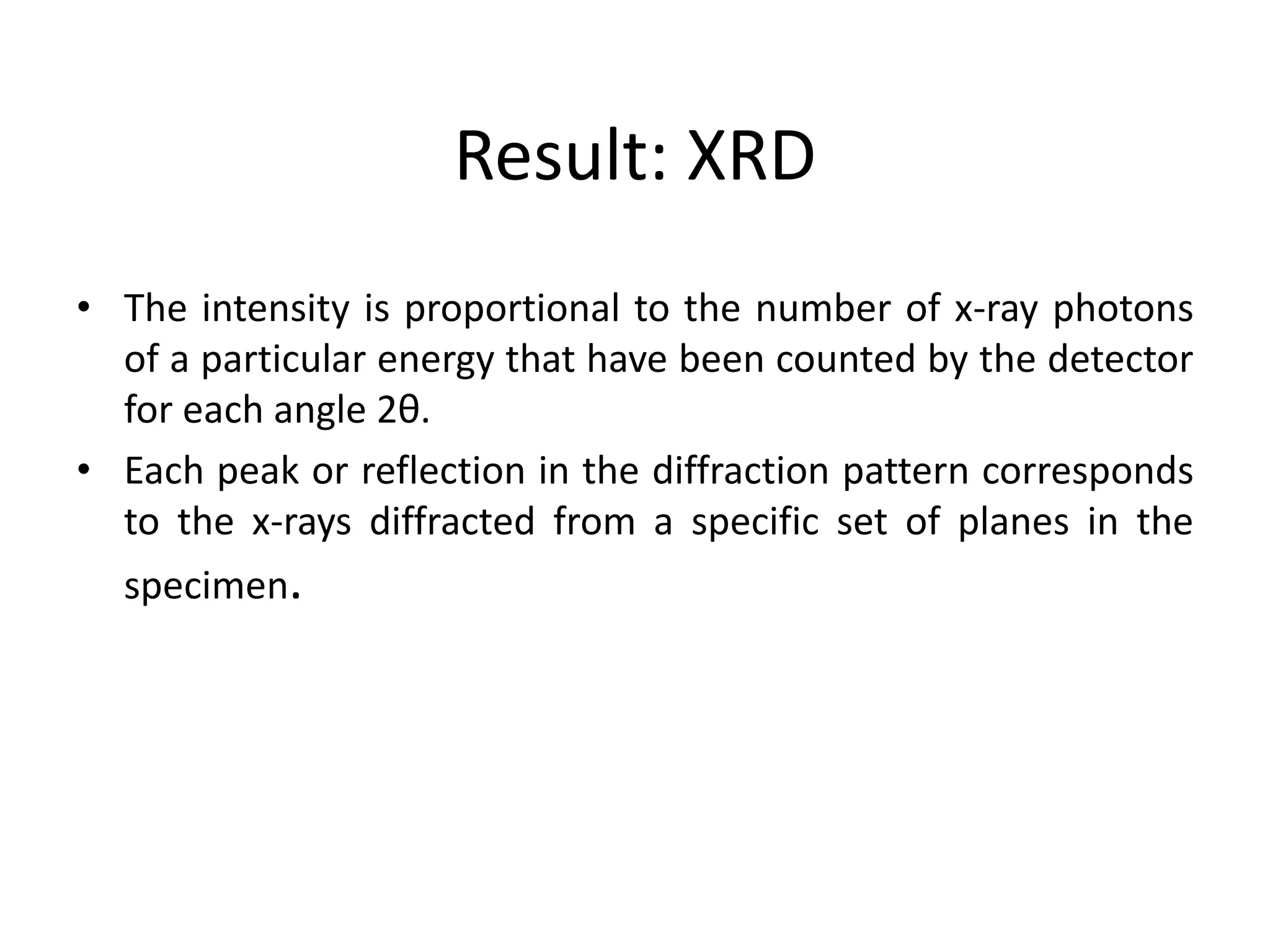

![Aluminum

• 9 peaks: low with symmetry

• 9 different positions: 9 different crystal structure of Aluminum

• For example, the miller indices or hkl plane of the highest peak would be Al[111]

which it is either be a FCC or cubic structured. Meanwhile, the lowest peak would

be Al[420]

• Highest peak (intensity of 100%), it proved that the quantity of the Al [420] is

higher compared to other different Aluminum types.](https://image.slidesharecdn.com/mcpresentation-180508132453/75/Material-Characterization-of-Tensile-Bar-Slides-9-2048.jpg)