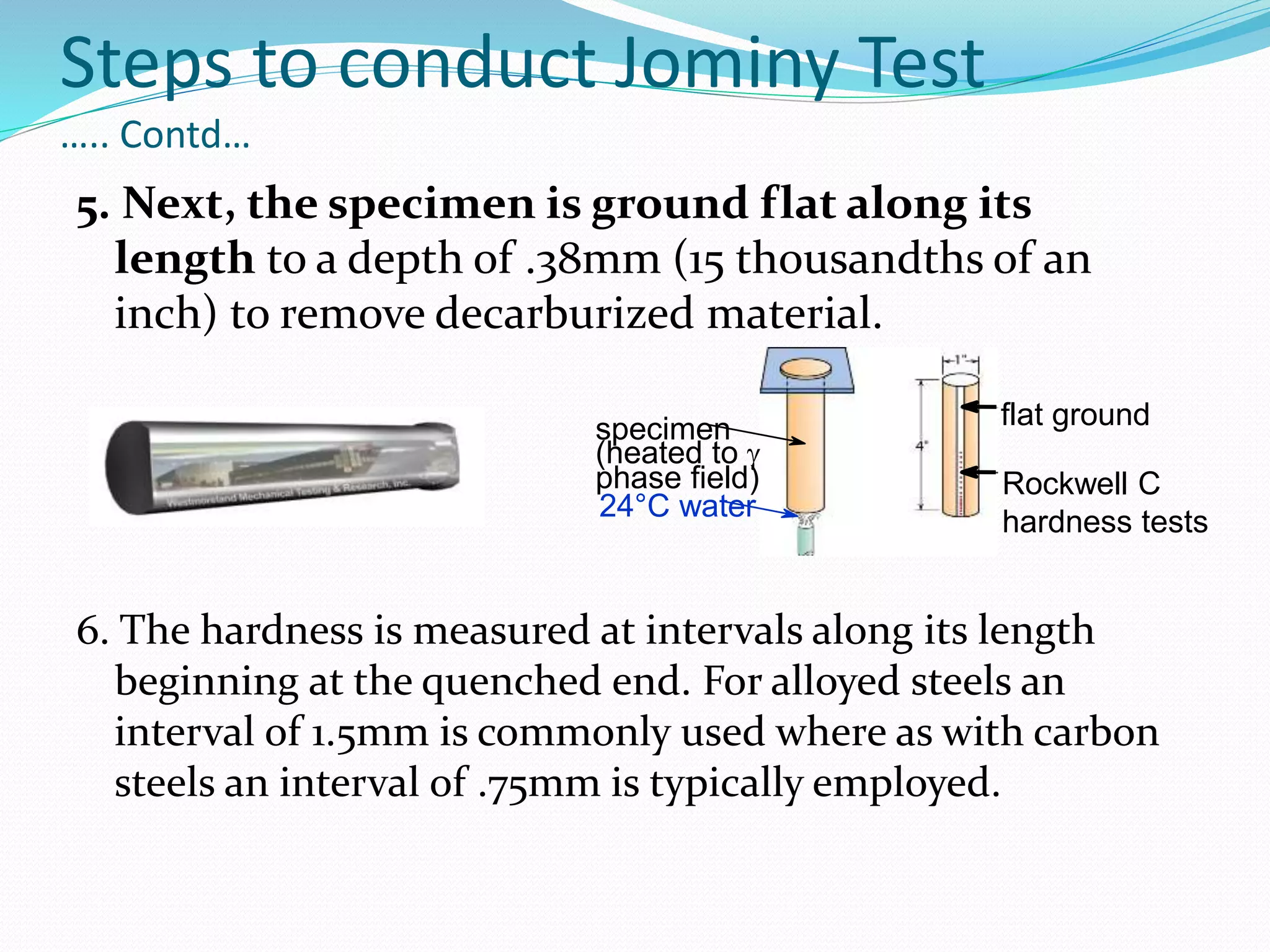

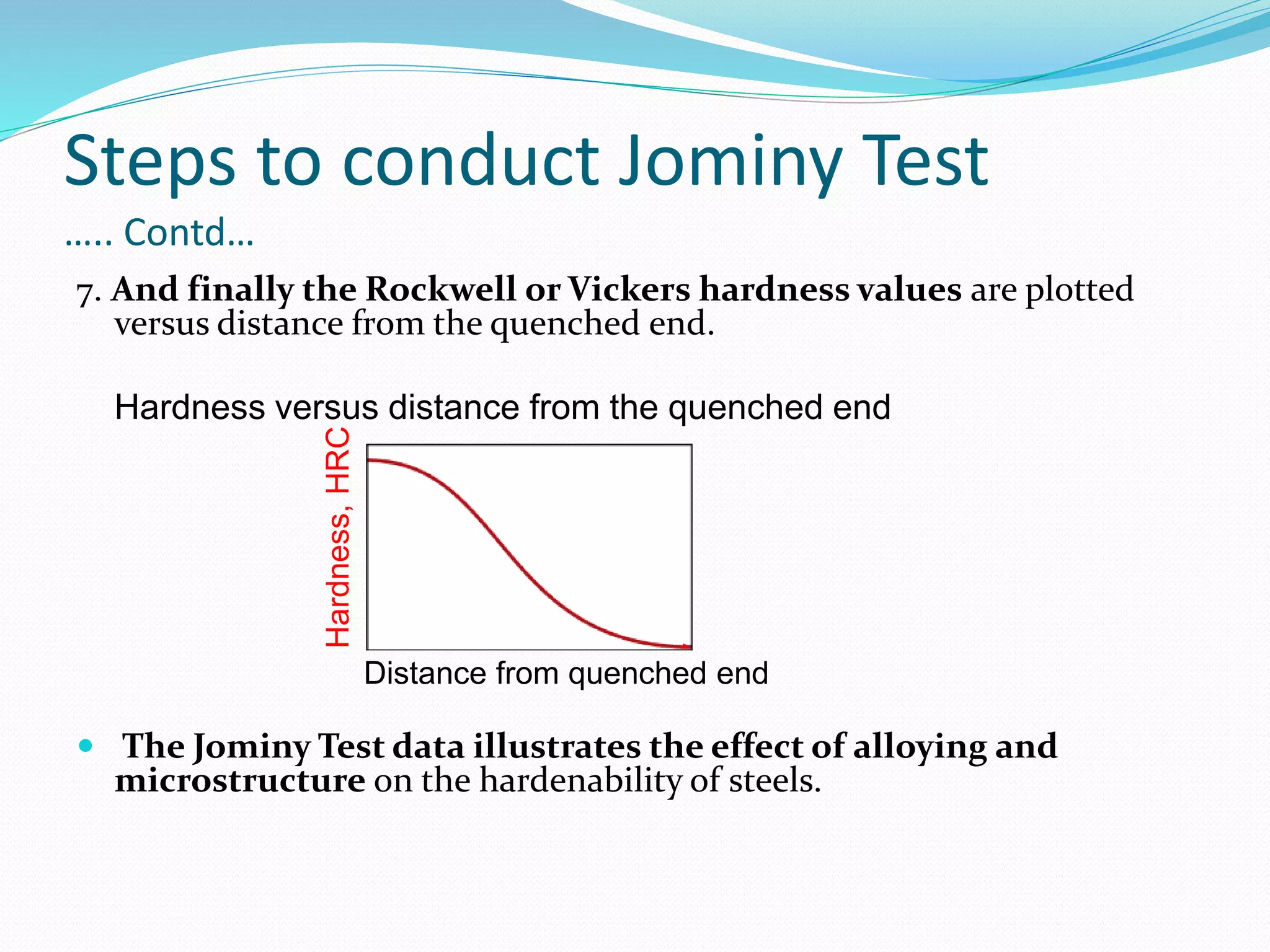

The document discusses the Jominy end quench test, which is used to measure the hardenability of steels. In the test, a cylindrical steel sample is uniformly heated, then quenched at one end with water to rapidly cool it. Hardness measurements are then taken at intervals along the sample's length from the quenched end. The results show decreasing hardness further from the quenched end, indicating how deep within the material the heat treatment can harden it. Alloying elements like chromium, molybdenum, and manganese can shift the hardness "nose" deeper, improving hardenability by slowing the transformation of austenite. The test provides critical information for selecting ste