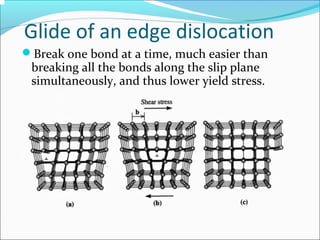

The document discusses the topic of plastic deformation in materials, focusing on mechanisms such as translational and twin glide, the role of dislocations, and various strengthening mechanisms. Key concepts include the effects of dislocations in polycrystalline materials and how factors like grain boundaries and thermally activated processes influence deformation. A literature review is included, outlining various studies related to plastic deformation mechanisms in different materials.