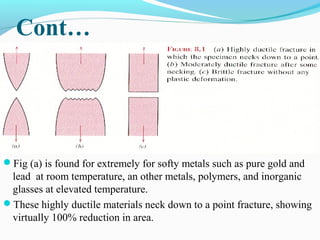

This document discusses fracture in materials under tensile loads. It describes two main types of fracture: ductile and brittle. Ductile fracture occurs through plastic deformation and the growth of microvoids, leading to necking of the material before failure. Brittle fracture occurs suddenly without plastic deformation through rapid crack propagation perpendicular to the tensile stress. The document outlines the stages and characteristics of ductile fracture in metals and compares it to the flat, cleavage surfaces of brittle fracture.