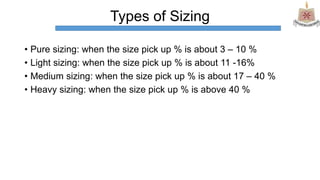

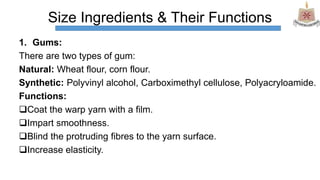

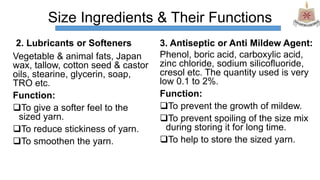

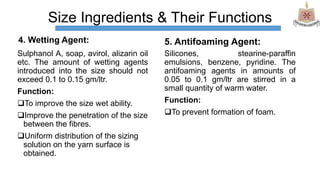

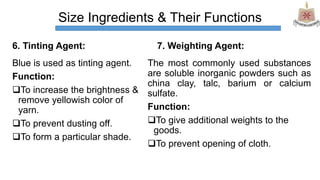

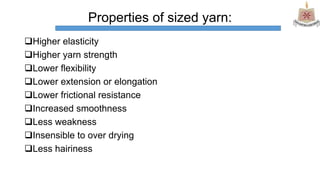

The document discusses the process of textile sizing, which involves applying an adhesive coating to yarn to enhance its properties, such as strength and smoothness. It details various sizing materials, their functions, types, and the advantages and disadvantages of sizing. Key ingredients include gums, lubricants, antiseptics, and agents for improved wetting and foaming control.