The document discusses the characteristics and treatment of wastewater from the textile industry, emphasizing the importance of effluent treatment plants (ETPs) to purify industrial wastewater for environmental safety. It outlines the various steps involved in the ETP process, including primary filtration, neutralization, chemical coagulation, biological treatment, and final filtration before discharge. International standards for the permissible limits of various pollutants in effluents are also provided to ensure safe discharge into the environment.

![2

Introduction:

Effluent is the stream of excess chemical liquor from an industry after using in original

operation. For example, the excess dye liquor extracted from the textile industry after dyeing

is an effluent of that dyeing industry. Effluent Treatment Plant or ETP is a waste water

treatment method which is particularly designed to purify industrial waste water for its reuse

and it’s aim is to release safe water to environment from the harmful effect caused by the

effluent. Textile industry uses numerous hazardous chemicals during processing such as heavy

metals, salts, surfactants, sulphite, and formaldehyde, which can cause major pollution in the

effluents’ receiving waters. Since textile waste water contains a diversity of impurities and

therefore specific treatment technology called ETP is required. The ETP Plant works at various

levels and involves various physical, chemical, biological and membrane processes to treat

waste water from different industrial sectors like chemicals, drugs, pharmaceutical, refineries,

dairy, ready mix plants & textile etc.

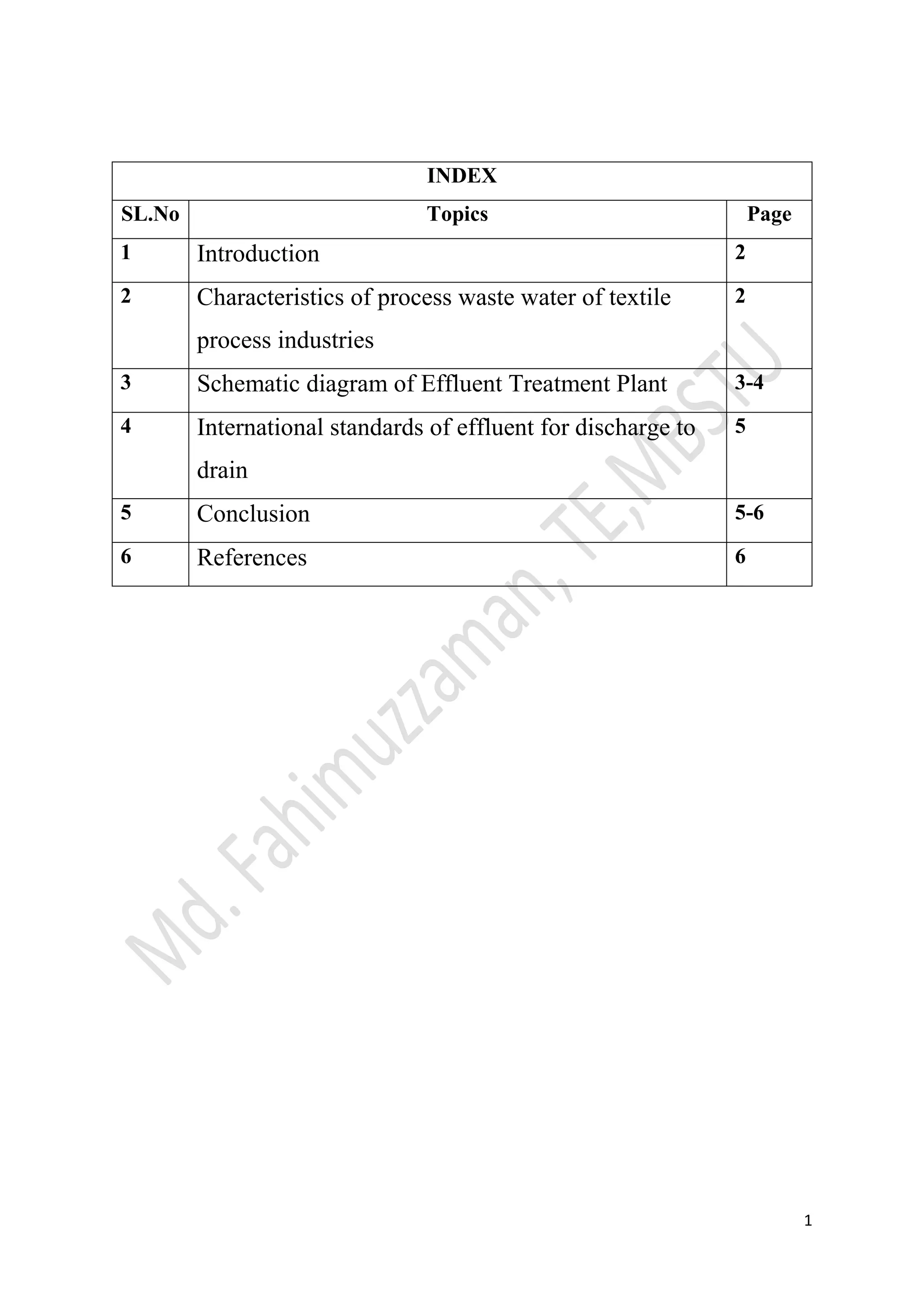

CHAREACTERISTICS OF PROCESS WASTE WATER OF TEXTILE PROCESSING

INDUSTRIES [1]:

Unit process Possible pollutants in the waste water Nature of the waste water

Desizing Starch, glucose, CMC, PVA, resin, fats

and waxes.

High BOD (35-50% of total)

Scouring NaOH, waxes, greases, Na2CO3 and

fragments of cloth.

Strongly alkaline weak color.

High BOD (30% of total)

Bleaching Na(OCl),Cl2, NaOH, H2O2, acid etc. Alkaline 5% of total BOD

Mercerisation NaOH Strongly alkaline low BOD

(less than 1%)

Dyeing Various dyes, salts, alkali, acid, Na2S,

Na2S2O4 and soaps, detergent etc.

Strongly colored fairly BOD

(6% of the total)

Printing Colors, starch, china clay, gum, oil,

mordents, acid, alkali, various metallic

salts etc.

Highly colored and oily

appearance BOD, (6-10% of

total)](https://image.slidesharecdn.com/etpplant-211203033929/75/Plan-an-ETP-with-detail-process-discussion-following-the-instructions-2-2048.jpg)

![3

Finishing Traces of starch, tallow and different

finishing agents.

Low BOD (2-4% of total)

Schematic diagram of Effluent Treatment Plant [2]

Step-1: Primary Filtration

It is the first stage of effluent treatment plant, where effluent is come from weav-ing, dyeing,

printing or finishing unit. Here primary filtration is performed to remove the Coarse suspended

matters such as rags, pieces of fabric, fibres, yarns and lint are removed. Bar screens and

mechanically cleaned fine screens remove most of the fibres..

Step-2: Cooling and mixing

In this stage, different types of effluent are mixed and cool down by rotating agitators or by blowing

compressed air from below.

Step-3: Neutralization by Acid/Alkali Dossing

Most of the effluent are alkaline some are acidic acidic which are comes from dyeing section. After

cooling and mixing; effluent is transferred to neutralization tank by the help of pump. Here, acid or

alkali is mixed to neutralize the effluent. A pH meter is placed in the neutralization tank.](https://image.slidesharecdn.com/etpplant-211203033929/75/Plan-an-ETP-with-detail-process-discussion-following-the-instructions-3-2048.jpg)

![5

After completing all process before discharging drain final filtration done here and separate the

sludge and water.

Step-9: Discharge to drain

After completion of all the process, the effluent becomes purify and it becomes safe to drain to

the environment.

INTERNATIONAL STANDARD OF EFFLUENT FOR DISCHARGE TO DRAIN[1]:

Serial No Characteristics Average quantity of

the effluent

Required limit to

discharge

01 BOD 250-500 mg/L 20-40 mg/L

02 COD 800-1200 mg/L 120-160 mg/L

03 Suspended solid 200-300 mg/L 20-40 mg/L

04 Settle able solid 0-5 mg/L Traces

05 Ammonia 20-30 mg/L 4-8 mg/L

06 Phosphate 3-5 mg/L 3-5 mg/L

07 Surfactant 30-40 mg/L 0.5-2 mg/L

08 Chloride 1000-1500 mg/L 1000-1500 mg/L

09 Sulphate 1000-1500 mg/L 1000-1500 mg/L

10 Color Colored Not perceptible

11 Oil and fat 30-40 mg/L < 5 mg/L

12 Phenol 3-5 mg/L < 0.05 mg/L

13 Temp. 45-0

500

C ≥450

C

Conclusion:

Effluent Treatment Plant (ETP) is essential to purify the waste water which is come from different stage

of textile industry like weaving, knitting, Scouring, bleaching, dyeing, finishing etc. It consists several

steps which sued to reduce hazardous effect by subsequent primary, secondary and tertiary treatment.](https://image.slidesharecdn.com/etpplant-211203033929/75/Plan-an-ETP-with-detail-process-discussion-following-the-instructions-5-2048.jpg)

![6

Primary treatment used to remove of a portion of the suspended solids and organic matter from

wastewater, Removal of biodegradable organic matter and suspended solids uses secondary

treatment alt last uses tertiary and advanced treatment for reuses of waste water. It is necessary

for all manufacturing industry to build a properly active ETP plant to safe our Environment.

References

[1] A. A. Mamun, “Study materials,” 2016.

[2] A. katiyar, “Working Procedure Of Effluent TreatmentPlant (ETP),” Textile Fashion Study, 2012.](https://image.slidesharecdn.com/etpplant-211203033929/75/Plan-an-ETP-with-detail-process-discussion-following-the-instructions-6-2048.jpg)