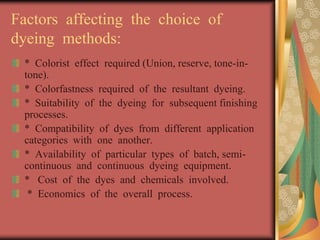

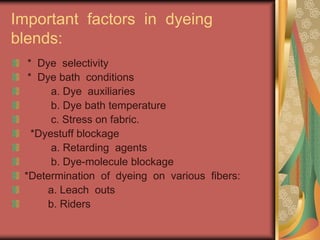

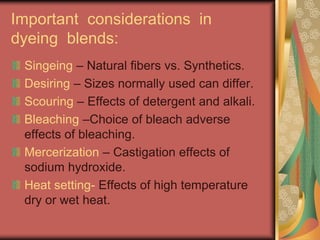

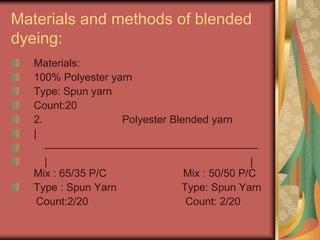

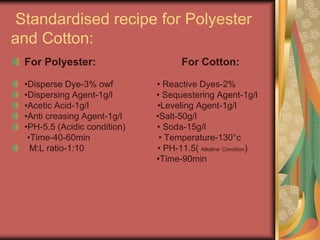

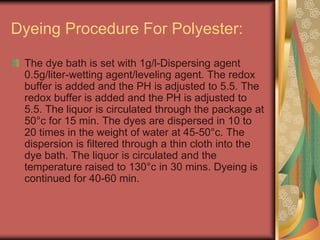

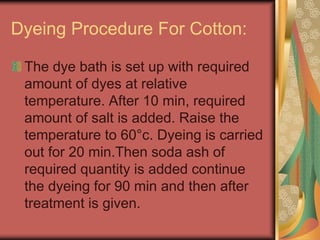

This document discusses blended dyeing of textiles. It begins with an introduction to blending different fiber types and the properties this can provide. It then describes the types of blends as fiber, combination fiber, or single yarns composed of blended fibers. Reasons for blending fibers include processing, improved properties, multi-colored fabrics, and cost. Key factors that affect dyeing methods are the desired color effect, required colorfastness, compatibility with finishing processes, and costs. The document concludes by stating that learning about blended dyeing, procedures, recipes, and factors is important knowledge for textile students and their future careers.