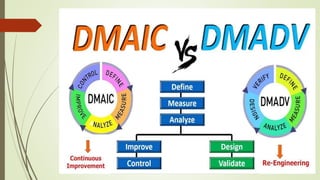

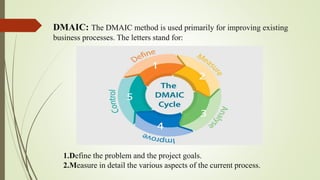

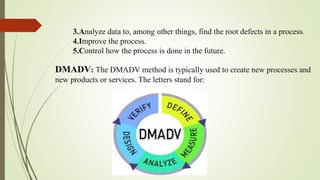

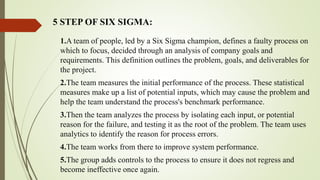

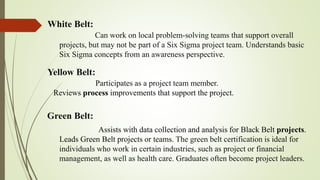

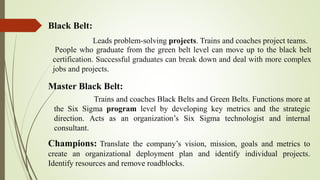

The document outlines Six Sigma, a quality management methodology developed by Bill Smith in 1986, aimed at process improvement and defect elimination in business and manufacturing. It explains key methodologies (DMAIC and DMADV), objectives, steps involved in Six Sigma projects, and the various ranking belts (White, Yellow, Green, Black, and Master Black) that signify expertise levels. The overall goal of Six Sigma is to enhance operational efficiency, reduce defects to 3.4 per million events, and improve customer satisfaction through systematic data-driven processes.