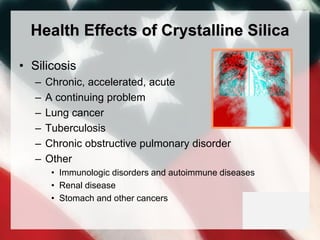

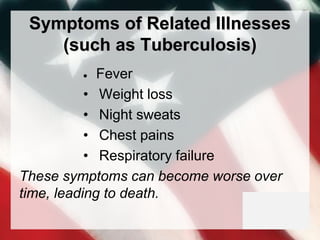

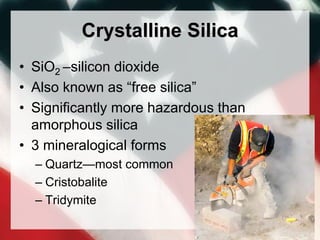

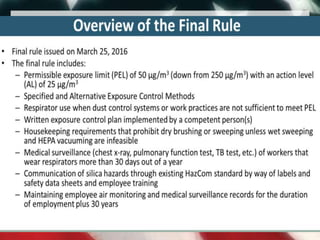

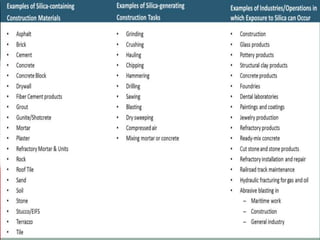

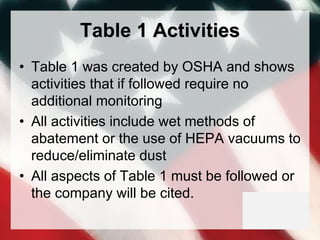

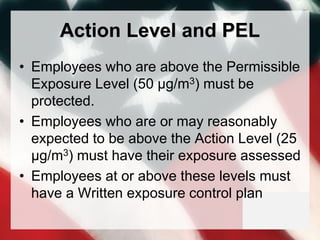

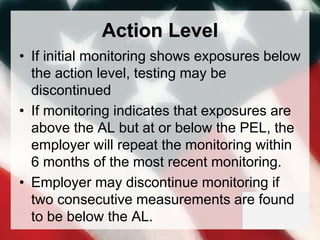

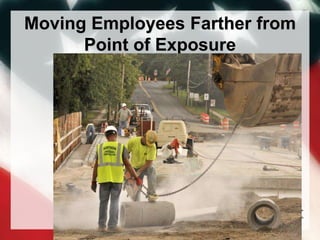

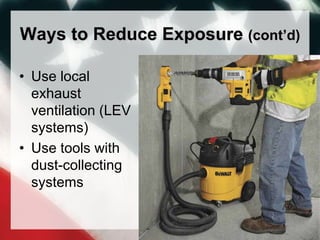

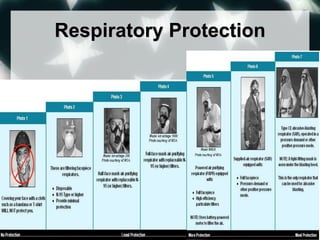

The document outlines safety requirements regarding crystalline silica, emphasizing health risks such as silicosis and lung cancer. It details OSHA's Table 1, which specifies activities and the necessary controls to mitigate silica exposure, highlighting the importance of monitoring and respiratory protection. Companies must implement a silica safety program, provide training, and ensure compliance with exposure limits to protect workers from health hazards.