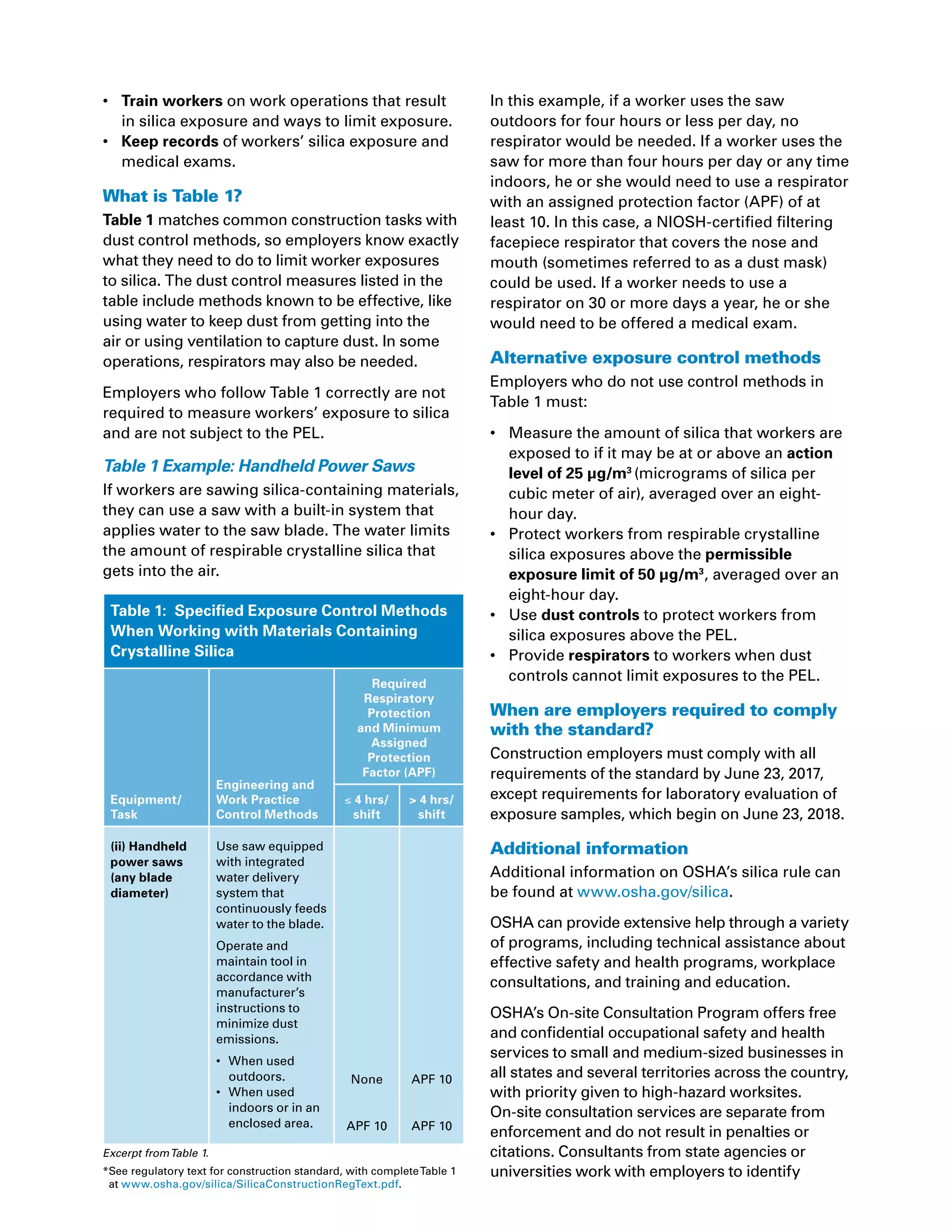

OSHA's crystalline silica rule for construction aims to protect about two million workers from respirable crystalline silica exposure, which can lead to severe health issues like silicosis and lung cancer. The standard requires employers to limit silica exposure through written control plans, training, and medical exams, while providing flexible compliance options, such as following an established table of dust control methods. Employers must comply with all requirements by June 23, 2017, with additional resources available from OSHA for assistance.