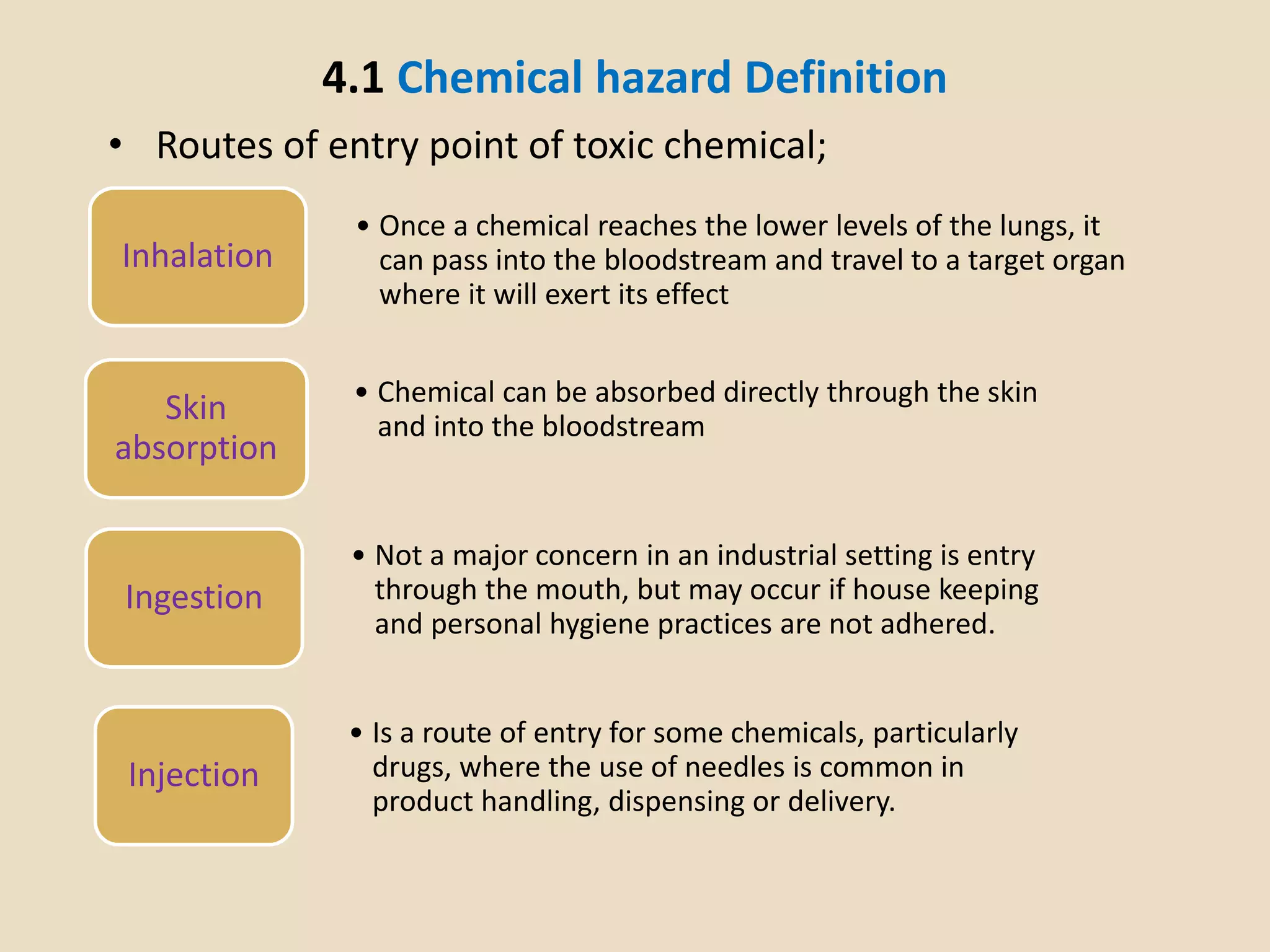

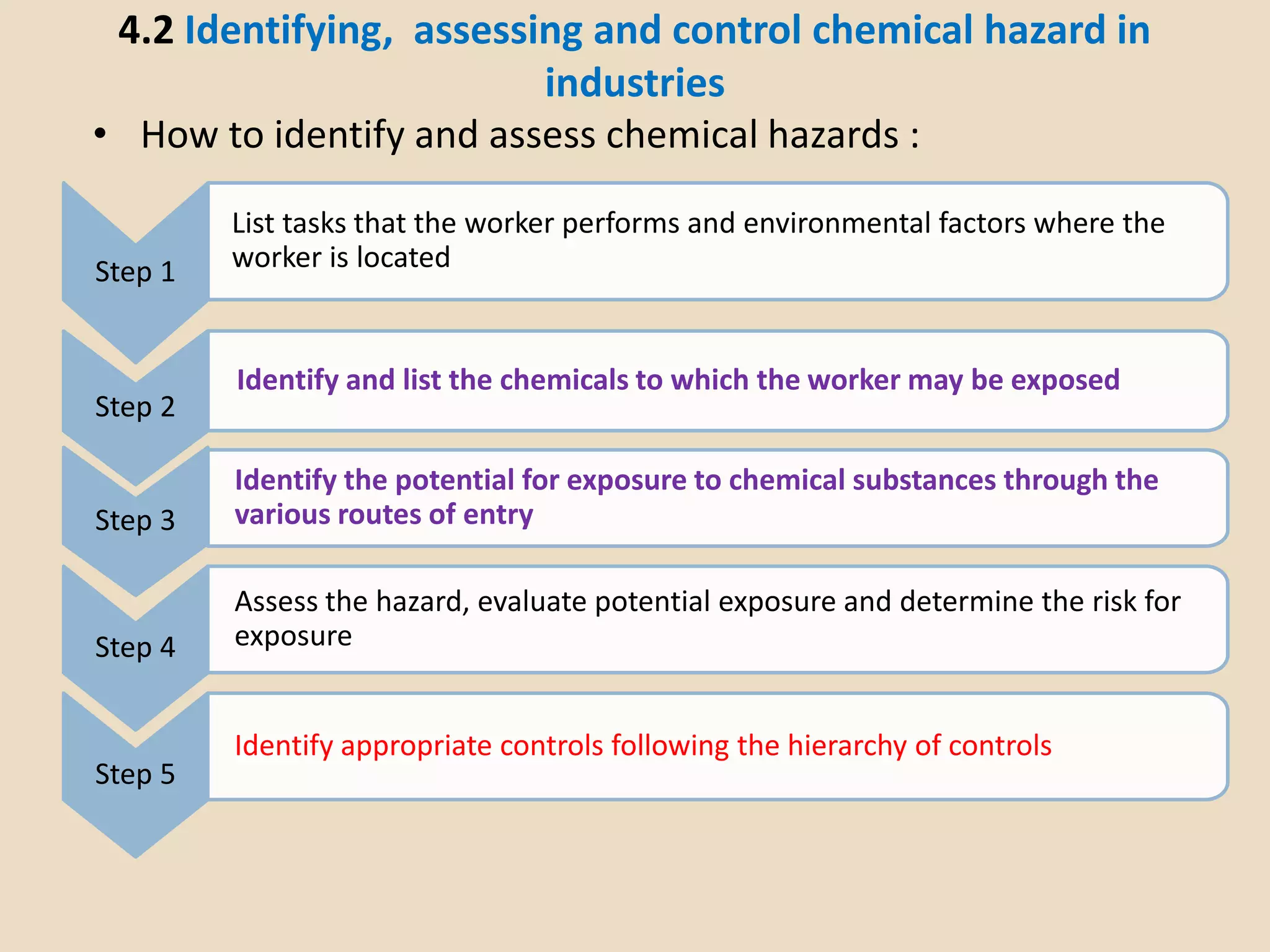

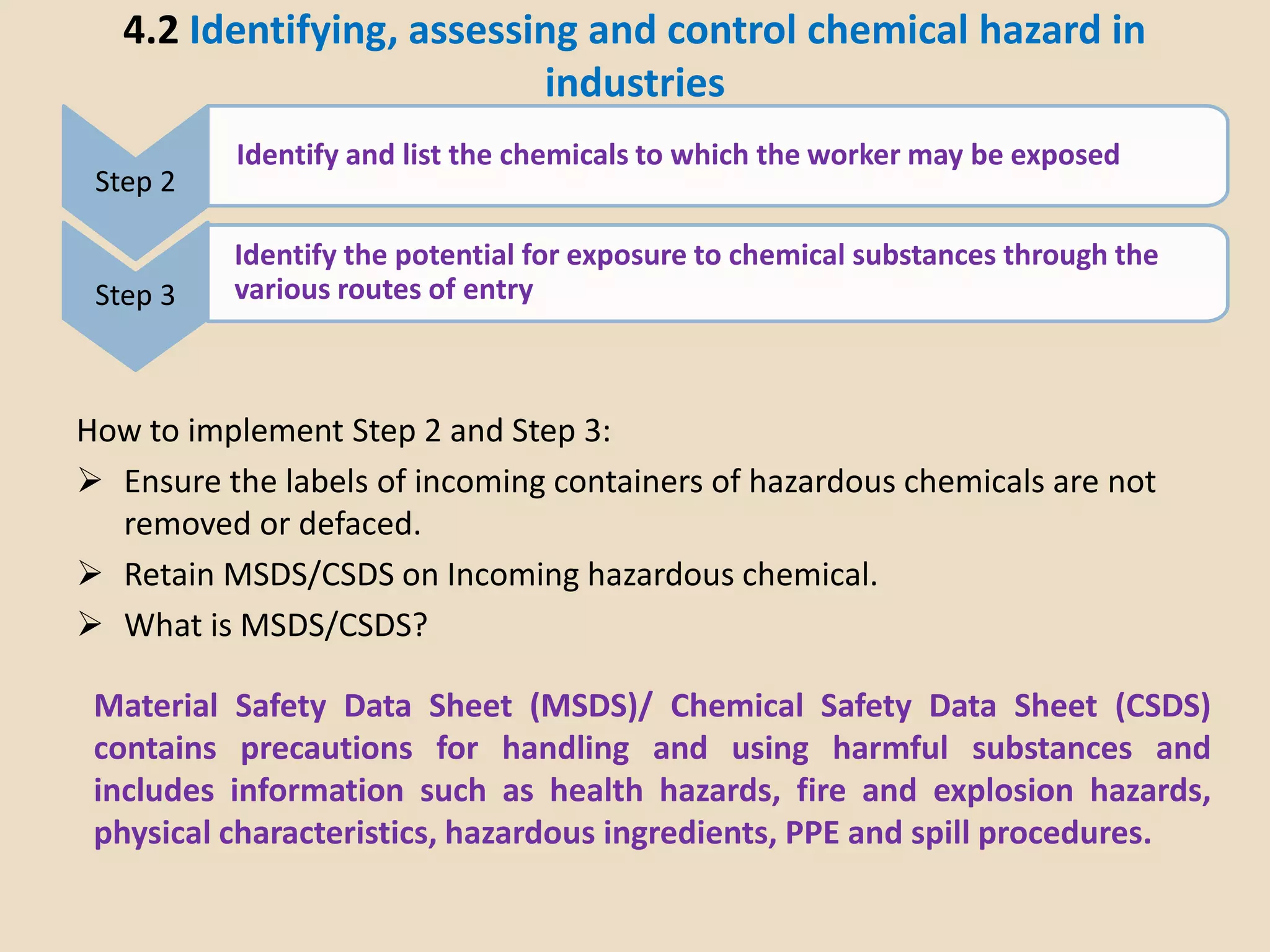

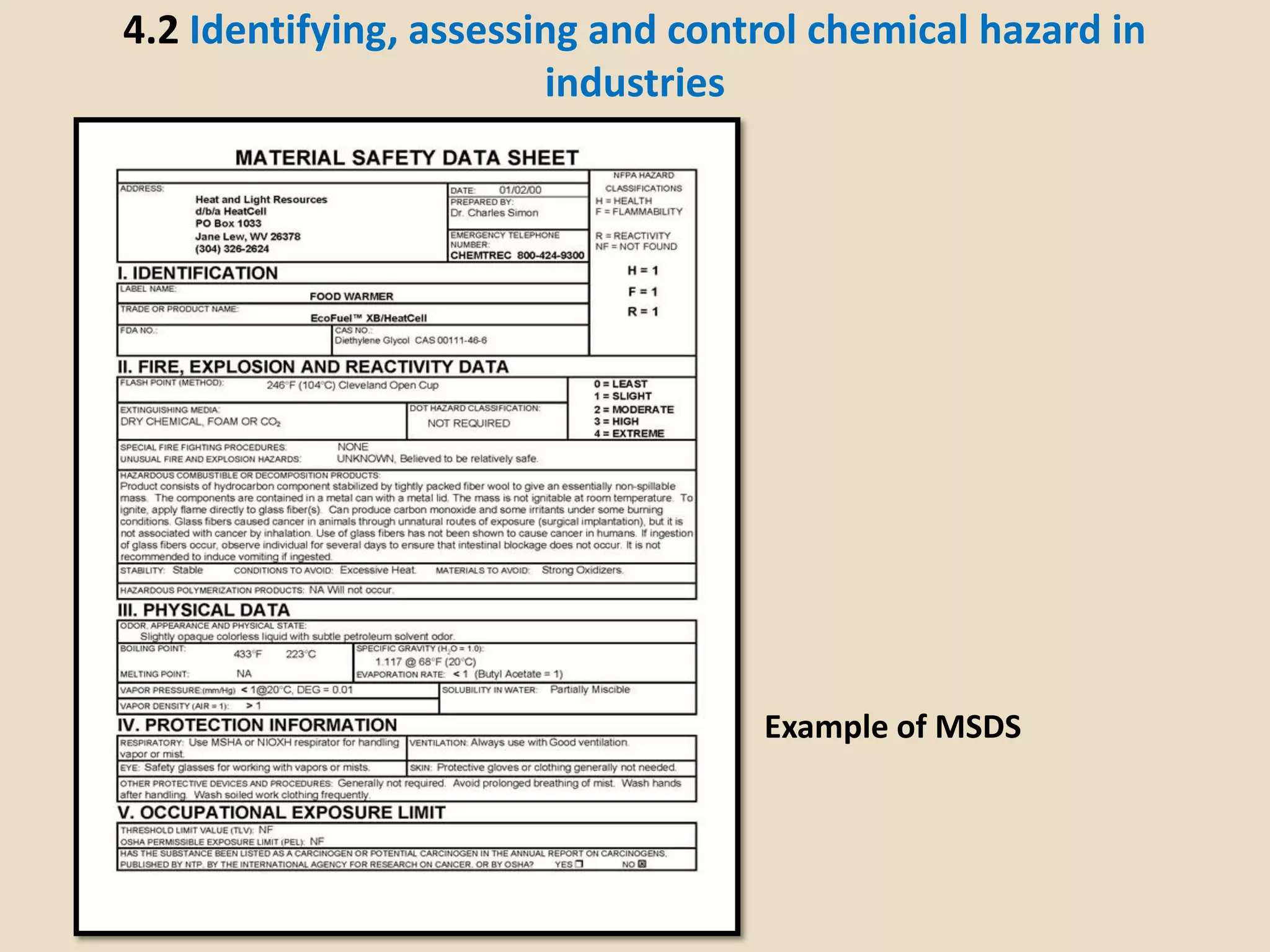

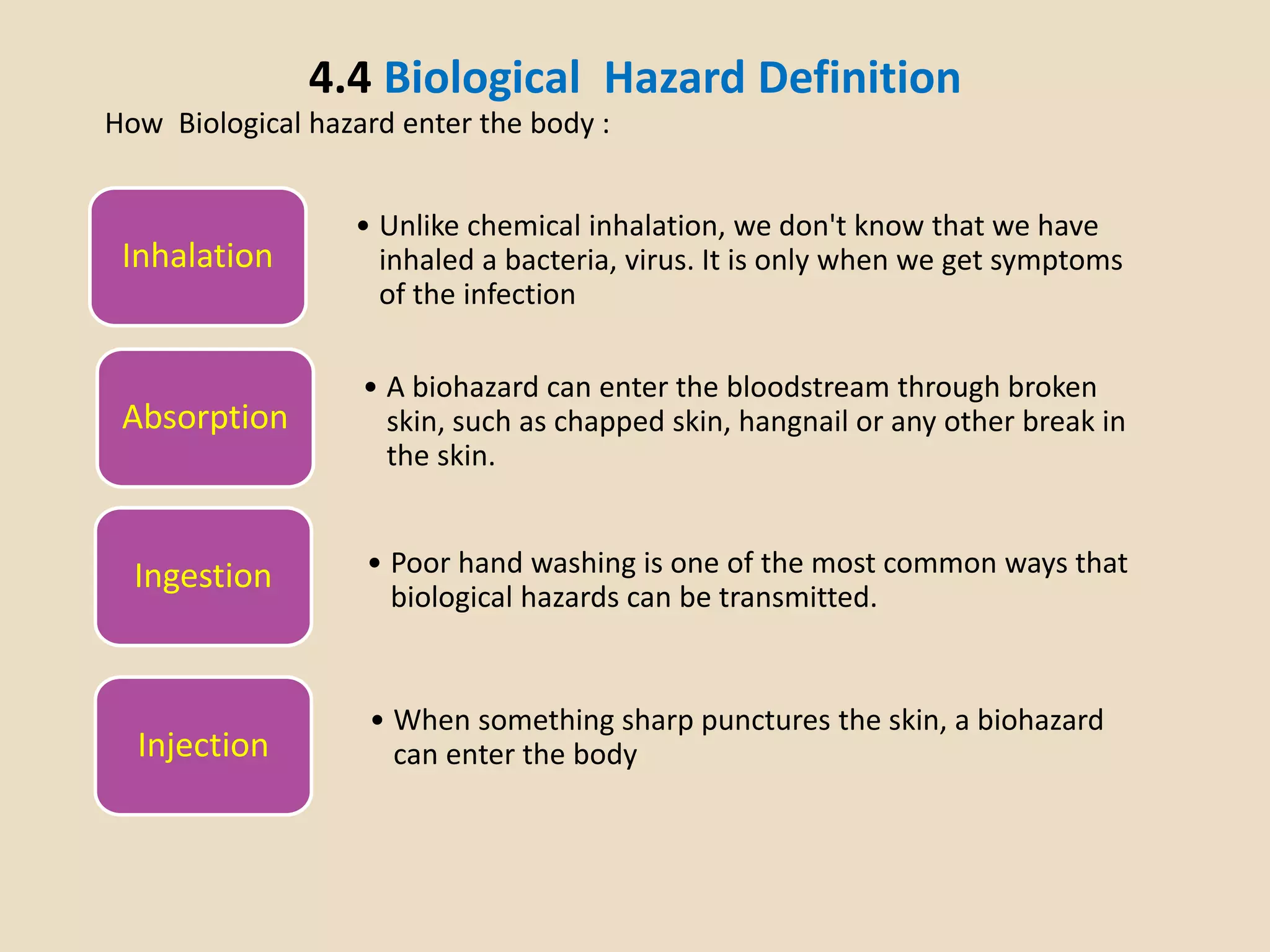

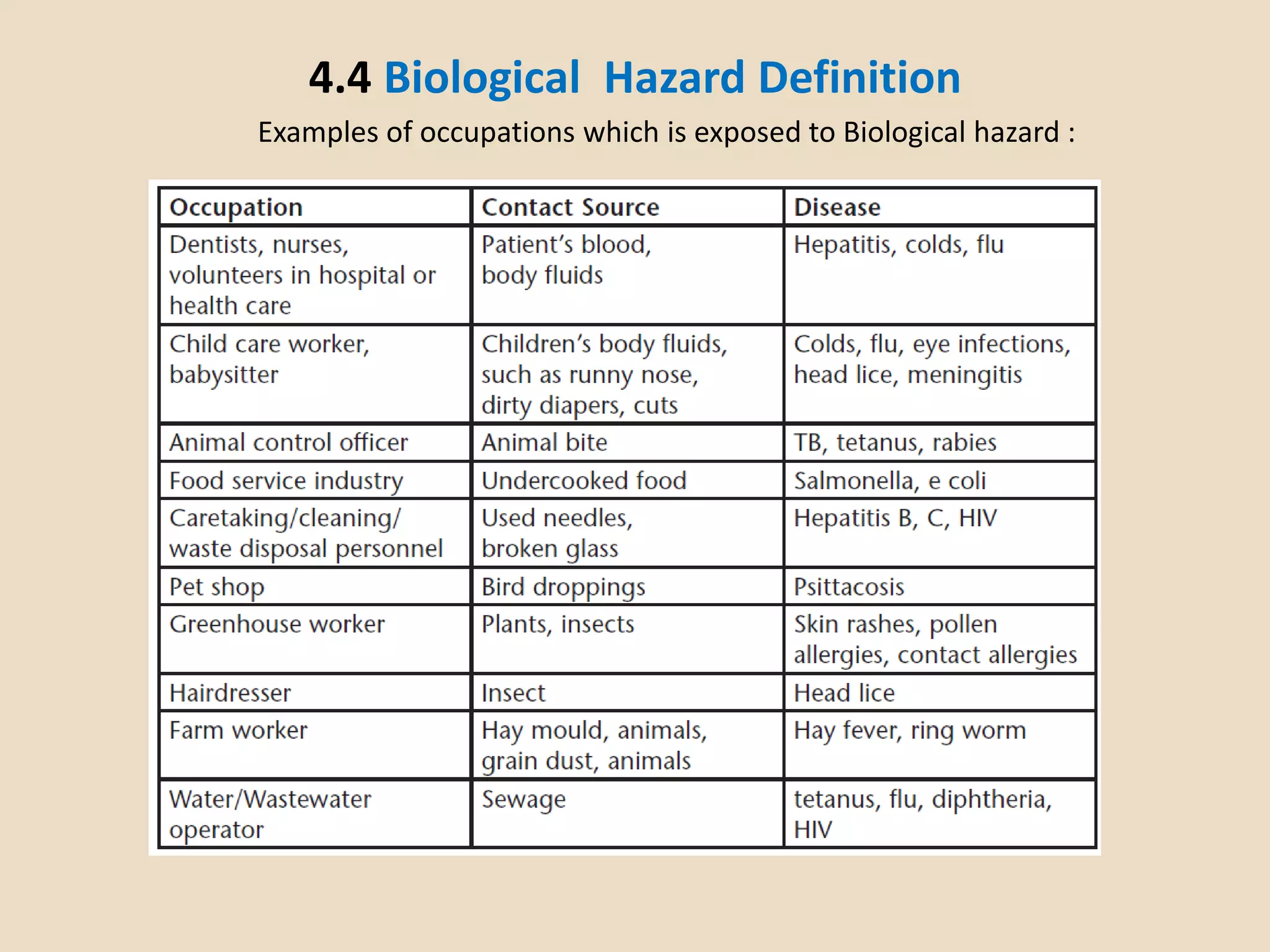

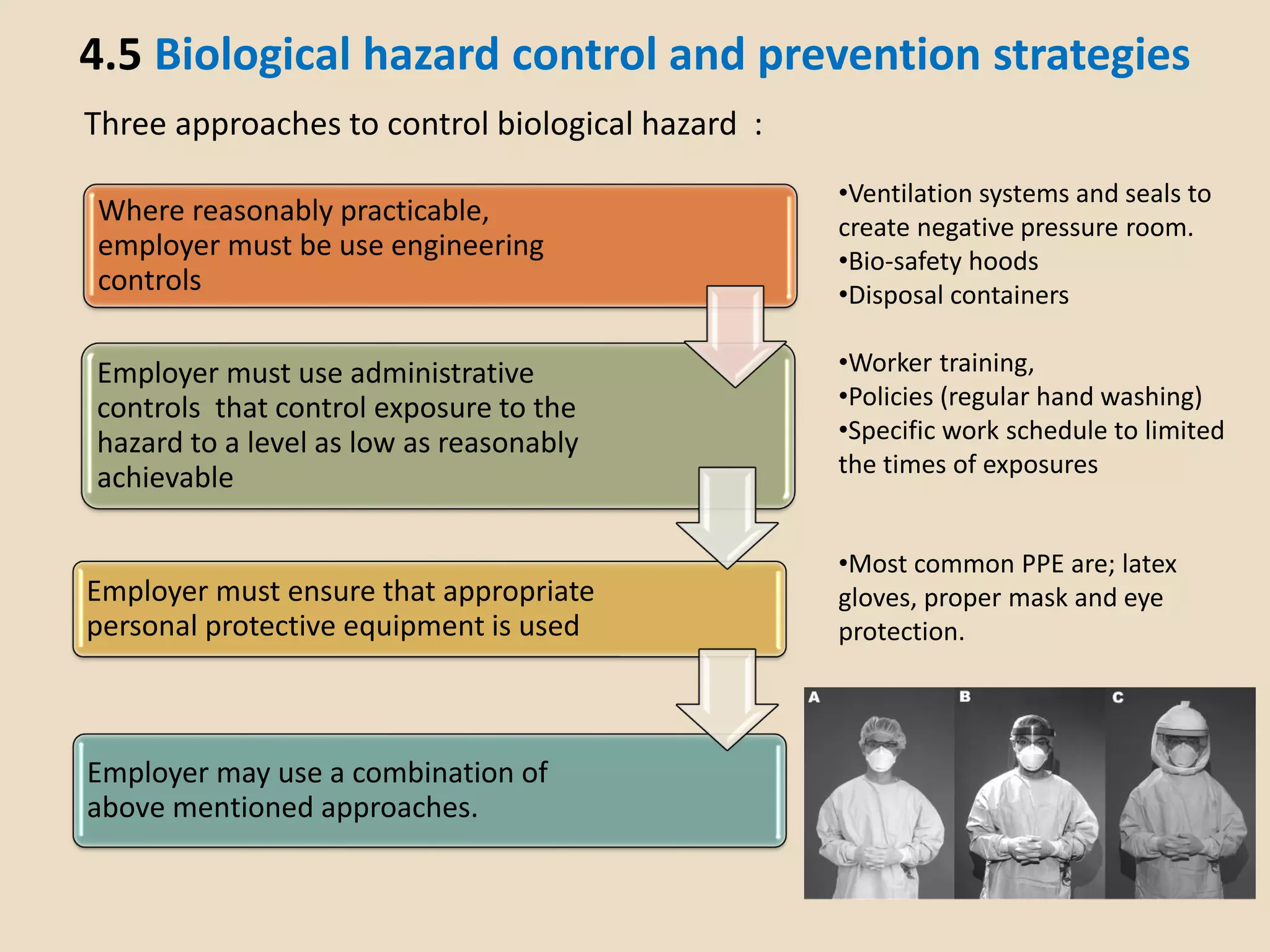

This document discusses chemical and biological hazards. It begins by outlining the learning outcomes, which are to describe chemical and biological hazards, explain control and prevention strategies, and discuss indoor air quality issues. It then covers definitions of chemical hazards, how to identify, assess, and control chemical hazards in industries. It discusses indoor air quality problems and sick building syndrome. Biological hazards are defined and examples are provided. Routes of biological hazard entry and examples of occupations exposed are outlined. Finally, strategies for controlling biological hazards are presented, including engineering, administrative, and personal protective controls.