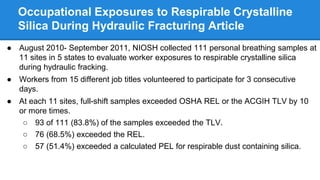

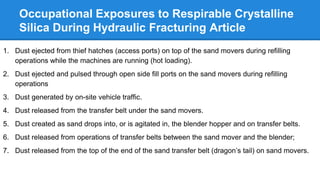

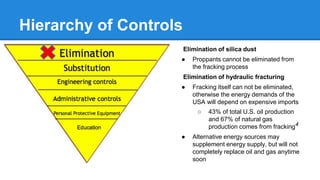

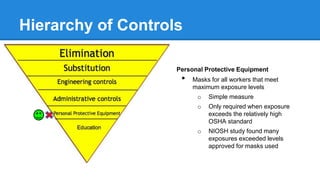

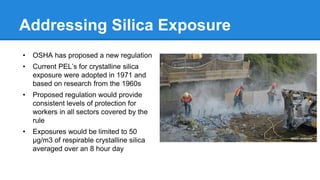

This document discusses the hazards of silica dust exposure for fracking workers. It outlines how workers are exposed to crystalline silica dust during fracking operations, which can lead to serious health issues like silicosis and lung cancer. It summarizes a NIOSH study that found over 80% of samples from fracking worker exposures exceeded recommended limits. While controls like ventilation and masks can help, many exposures still exceed approved limits for respiratory protection. Regulations and enforcement are needed to better protect workers from silica dust during fracking.

![Resources

OSHA. (2012). Worker Exposure to Crystalline Silica During Hydraulic Fracturing. Retrieved from

https://www.osha.gov/dts/hazardalerts/hydraulic_frac_hazard_alert.html1

Grossman, E. (2013). Silica exposure in fracking: Over 60 percent of workers may be excessively exposed. The

Pump Handle. 2

Esswein, J. E., Breitenstein, M., Snawder, J., Kiefer, M., and Sieber, K. W. (2013). Occupational Exposures to

Respirable Crystalline Silica During Hydraulic Fracturing. Journal of Occupational and Environmental Hygiene. 10:

347-356.3

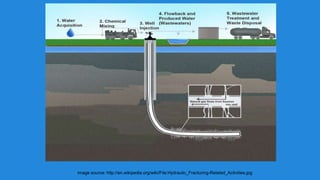

US Dept. of Energy. (2013). How is Shale Gas Produced? Retrieved from

http://energy.gov/sites/prod/files/2013/04/f0/how_is_shale_gas_produced.pdf.4

Proppant Specialists, LLC. (2008). Silica Sand [Material Safety and Data Sheet]. Retrieved from

http://oilandgas.ohiodnr.gov/portals/oilgas/_MSDS/fractech/Silica_Sand.pdf.5

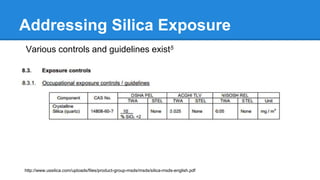

U.S. Silica Company. (2012). Silica Sand and Ground Sand [Material Safety and Data Sheet]. Retrieved from

http://www.ussilica.com/uploads/files/product-group-msds/msds/silica-msds-english.pdf.6](https://image.slidesharecdn.com/group13fracking-140511161250-phpapp02/85/Group13-fracking-23-320.jpg)