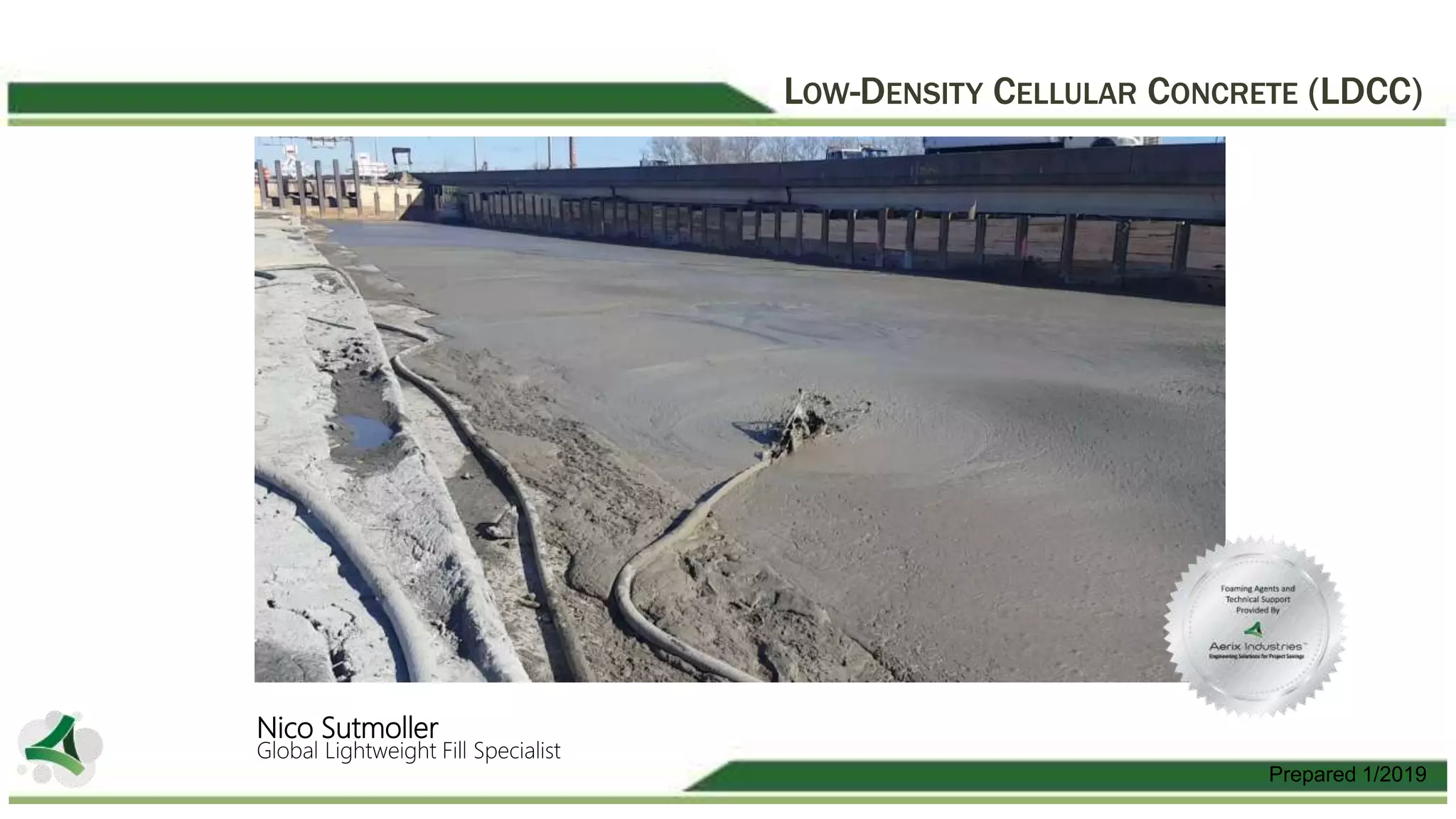

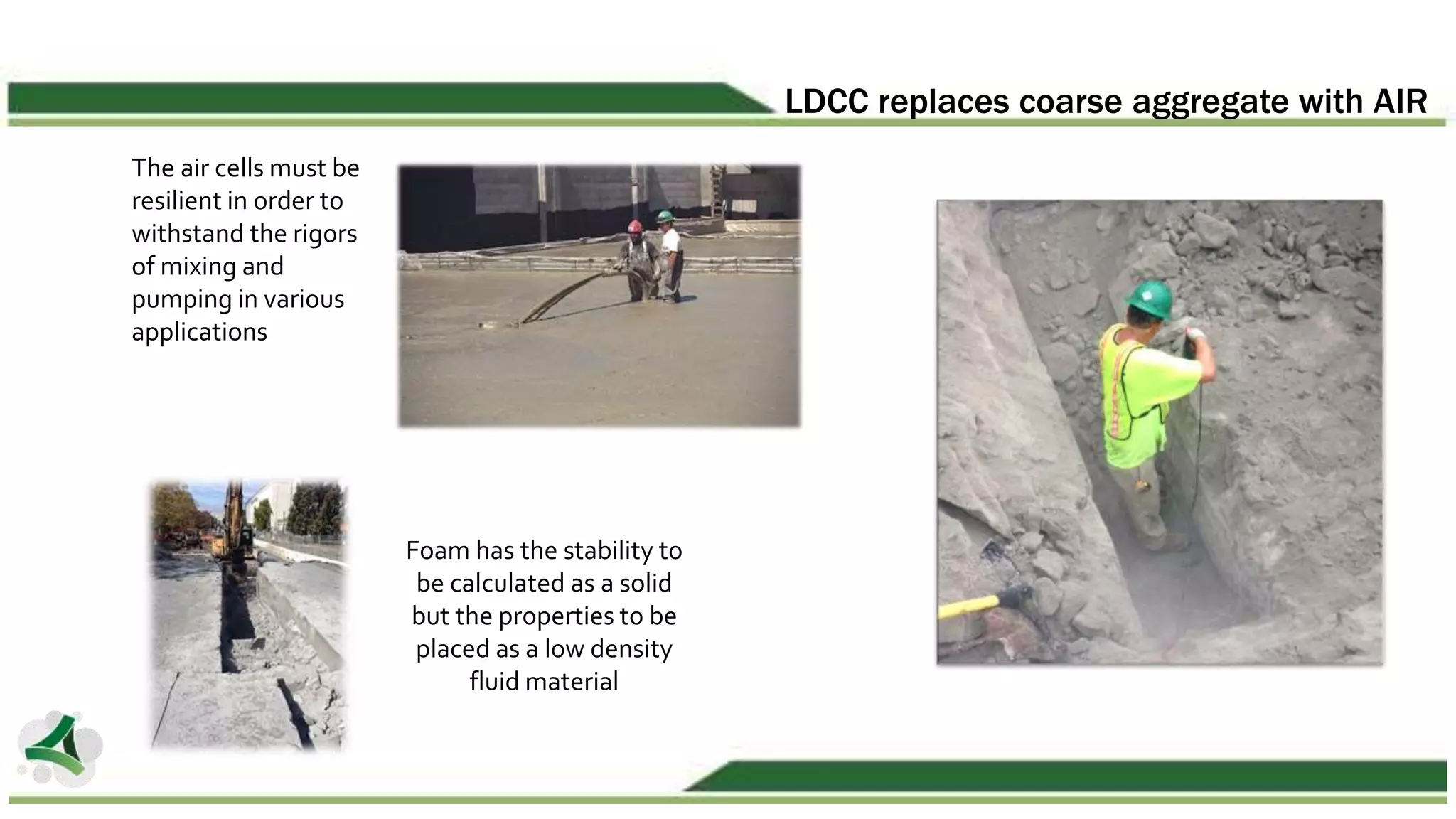

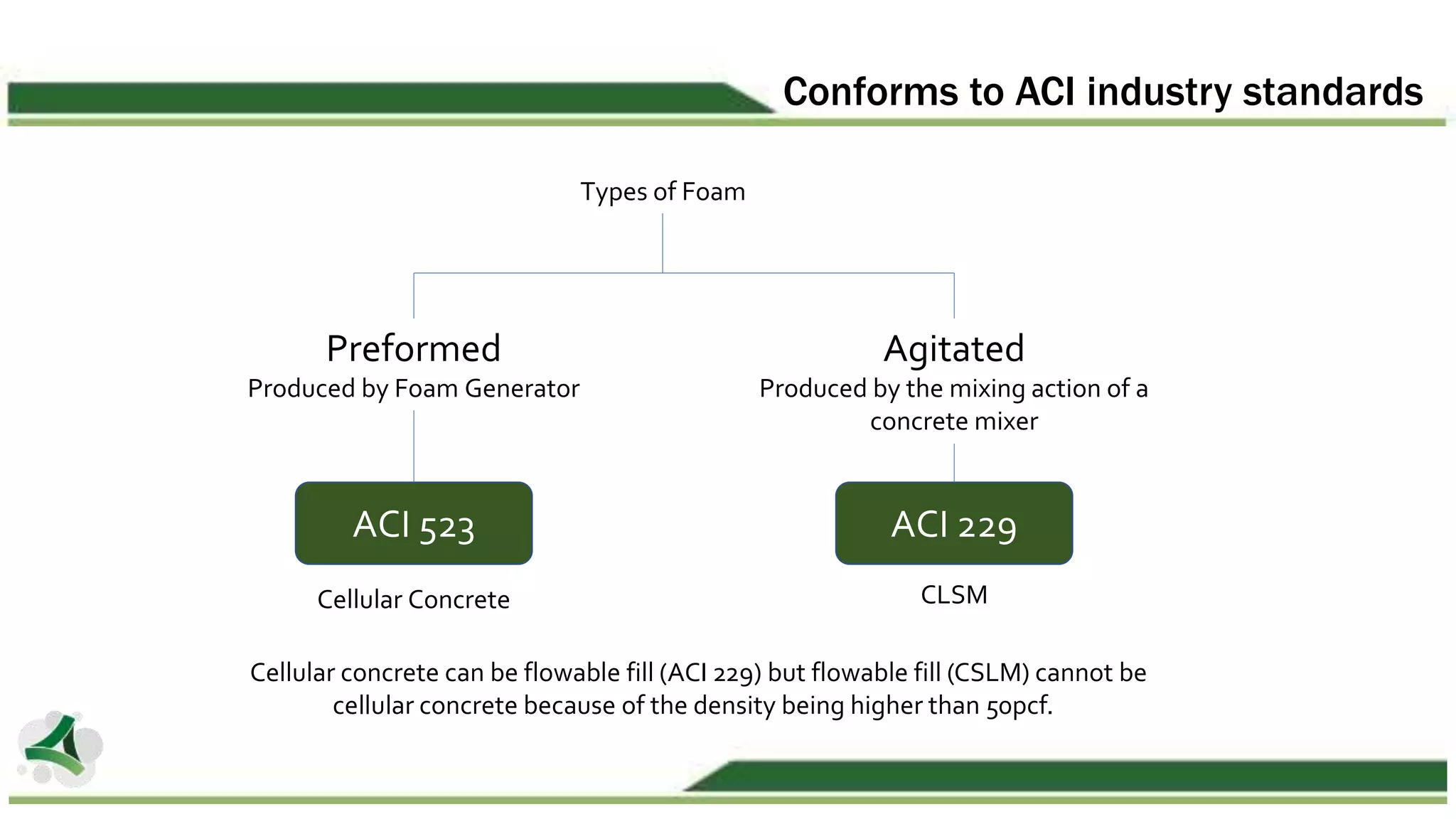

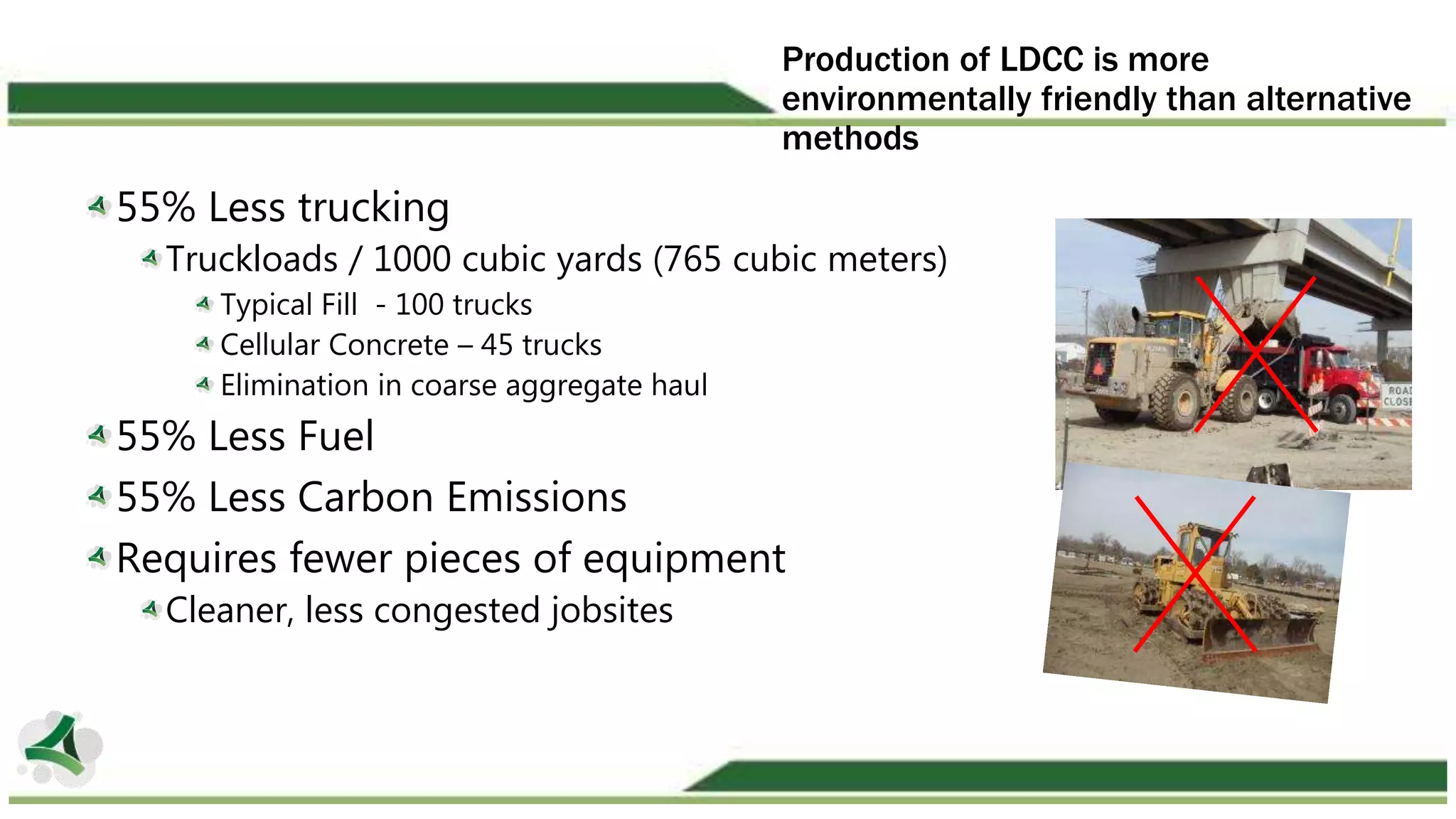

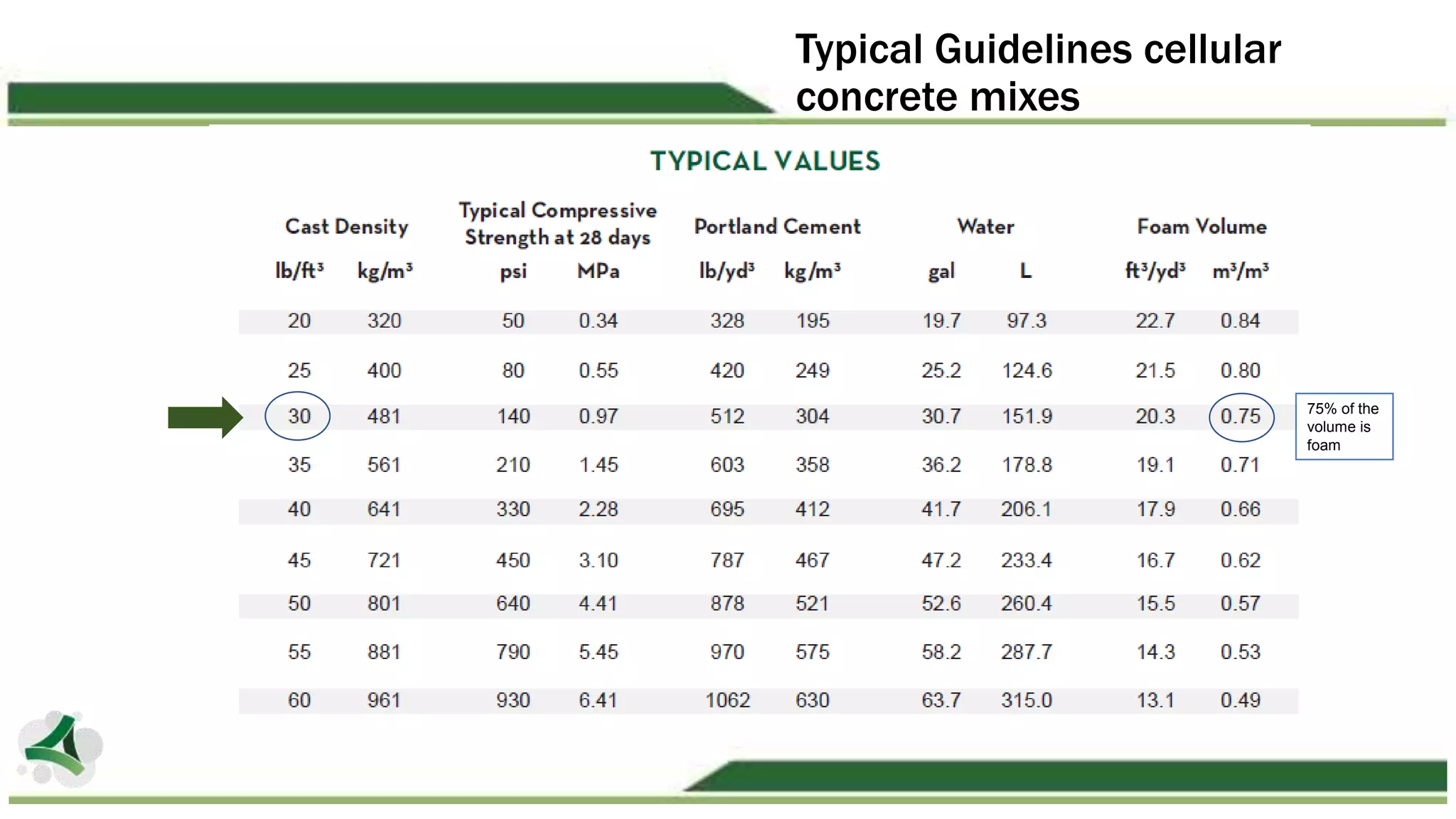

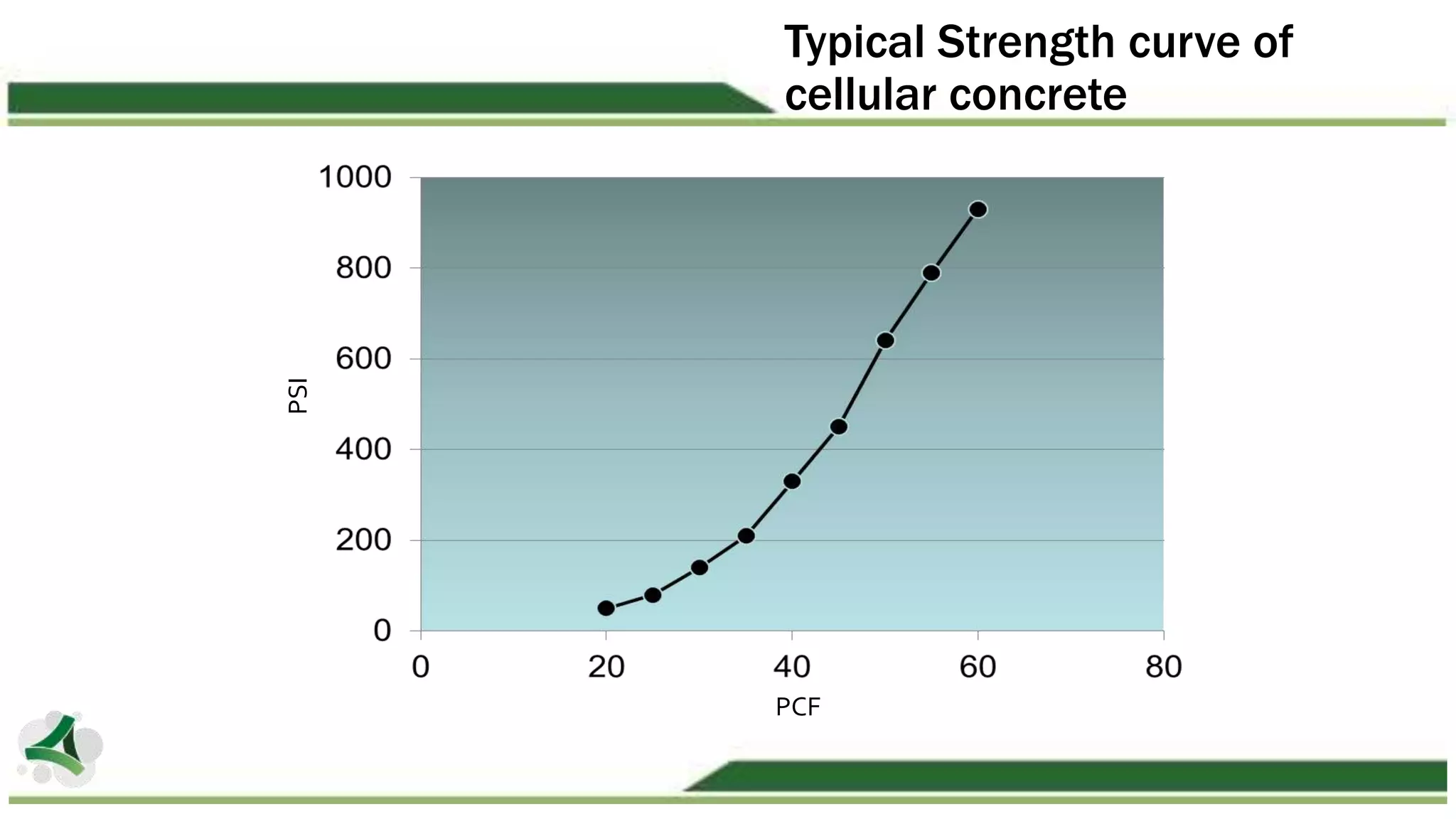

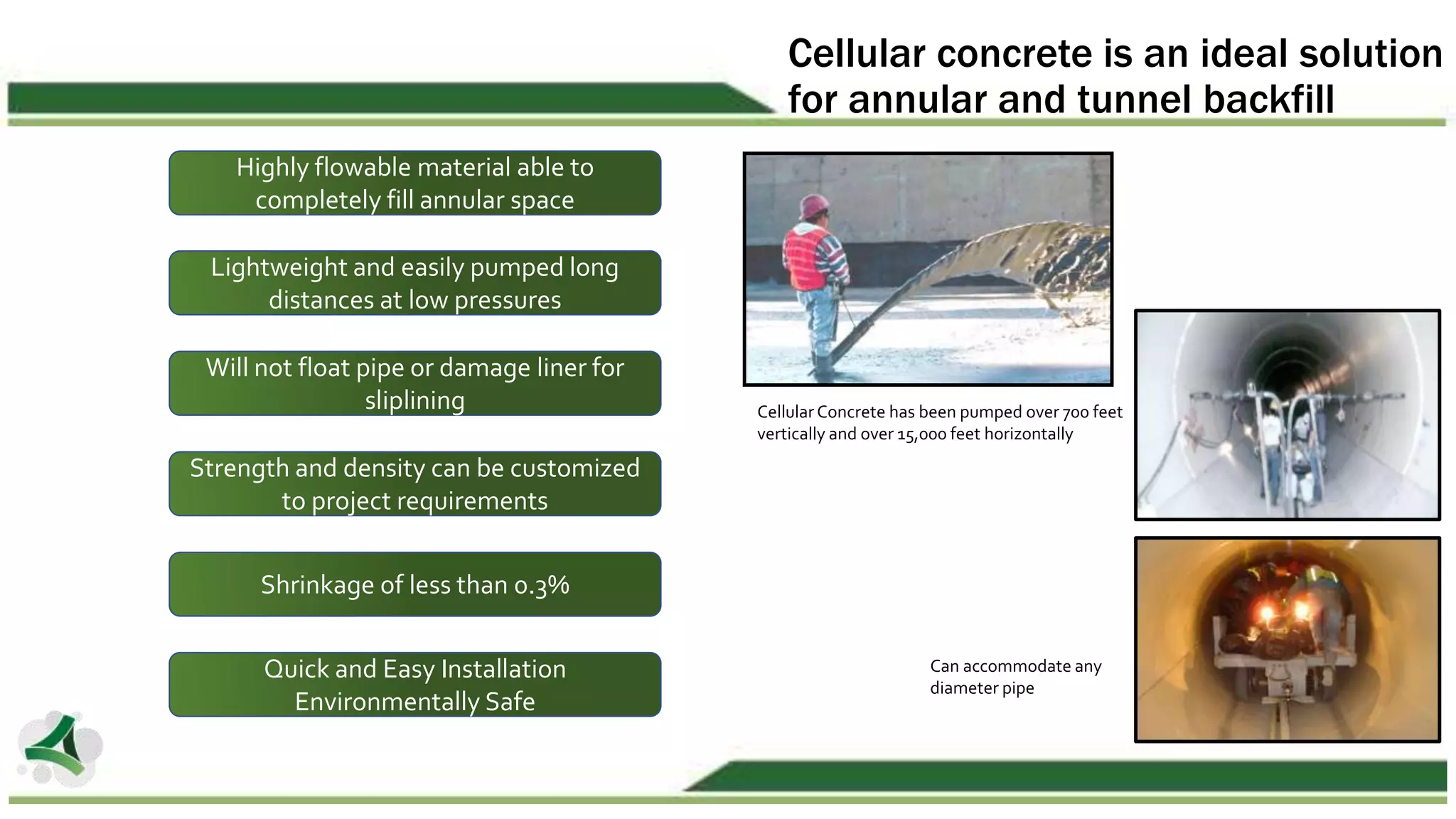

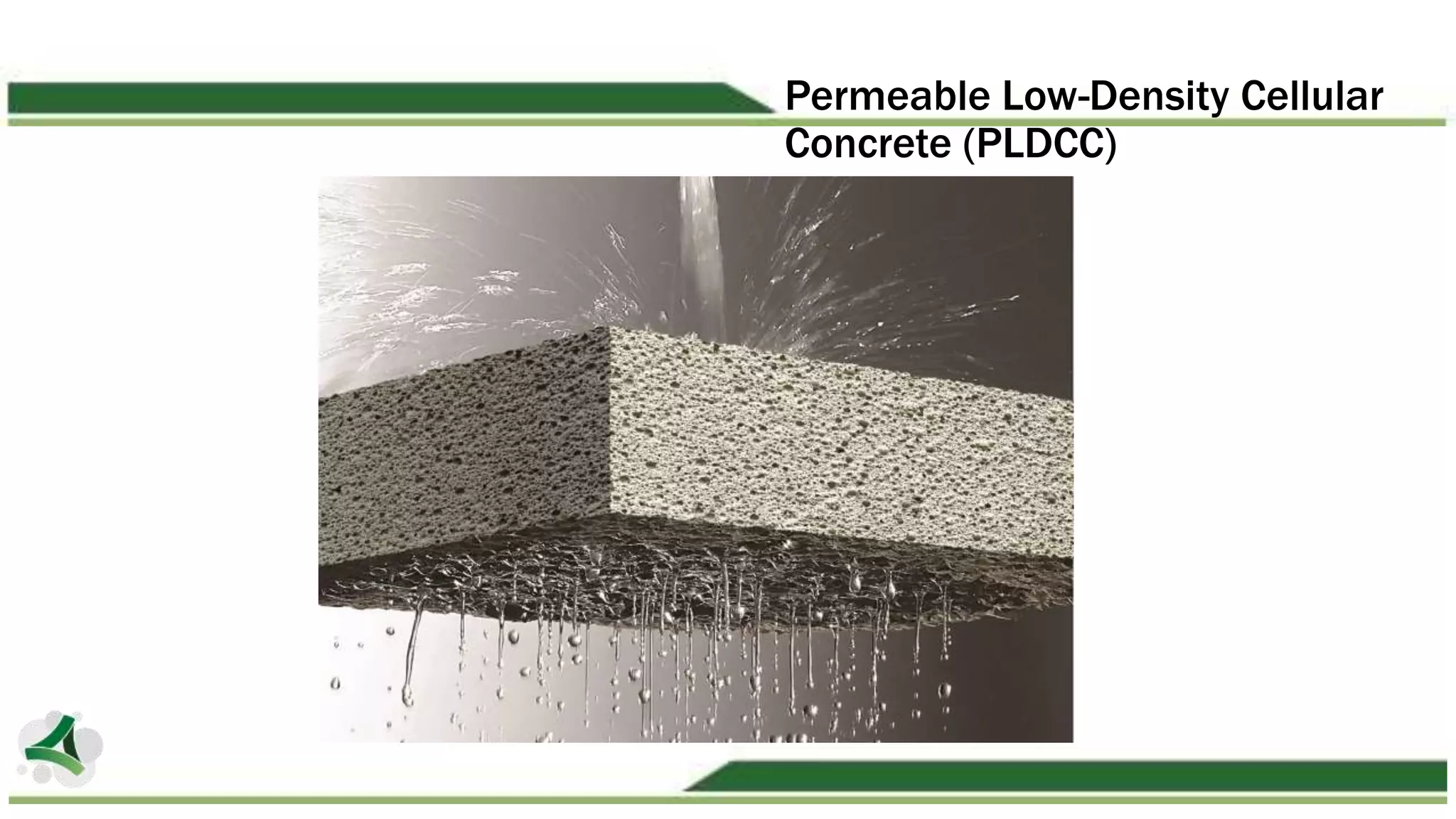

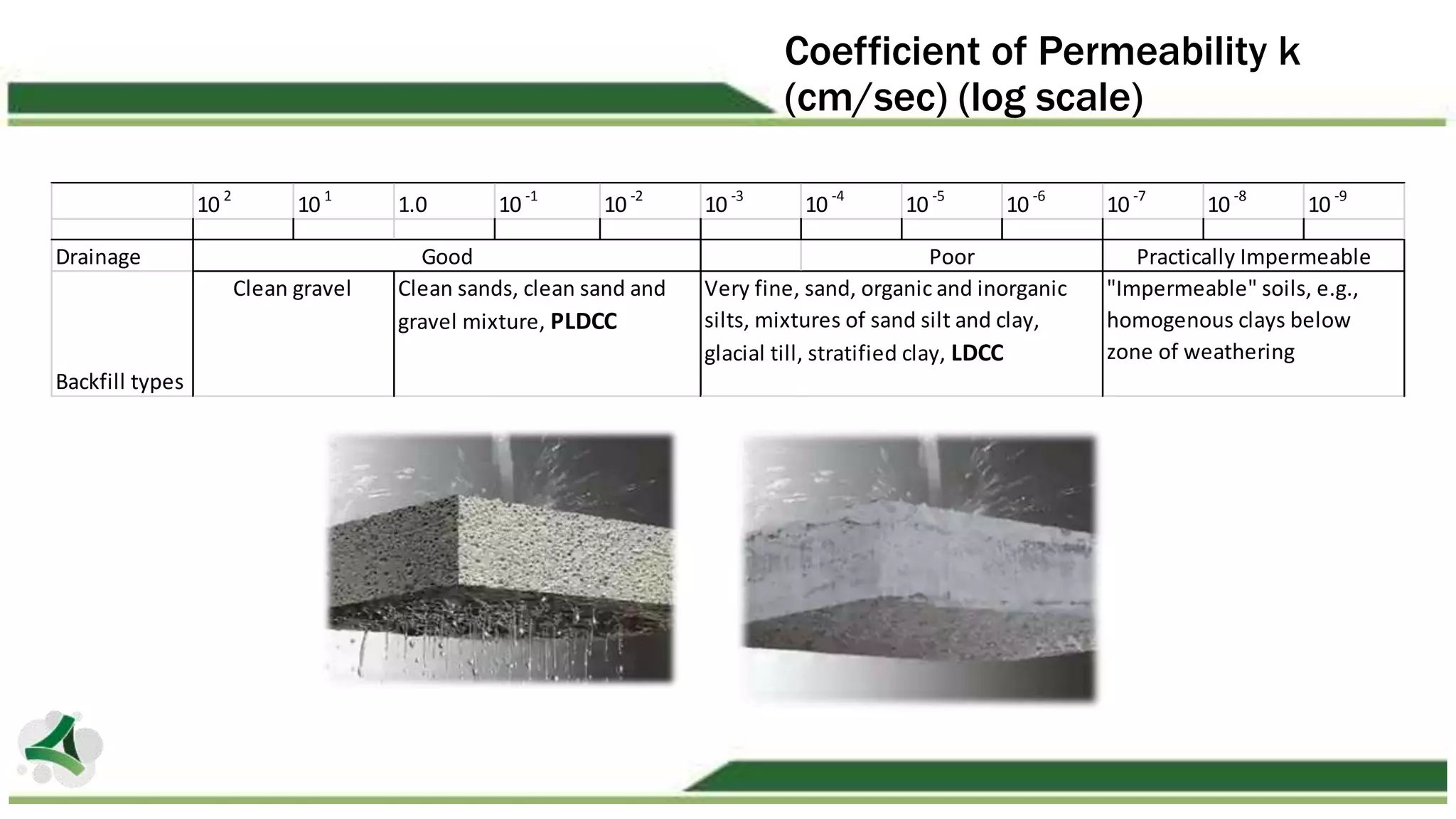

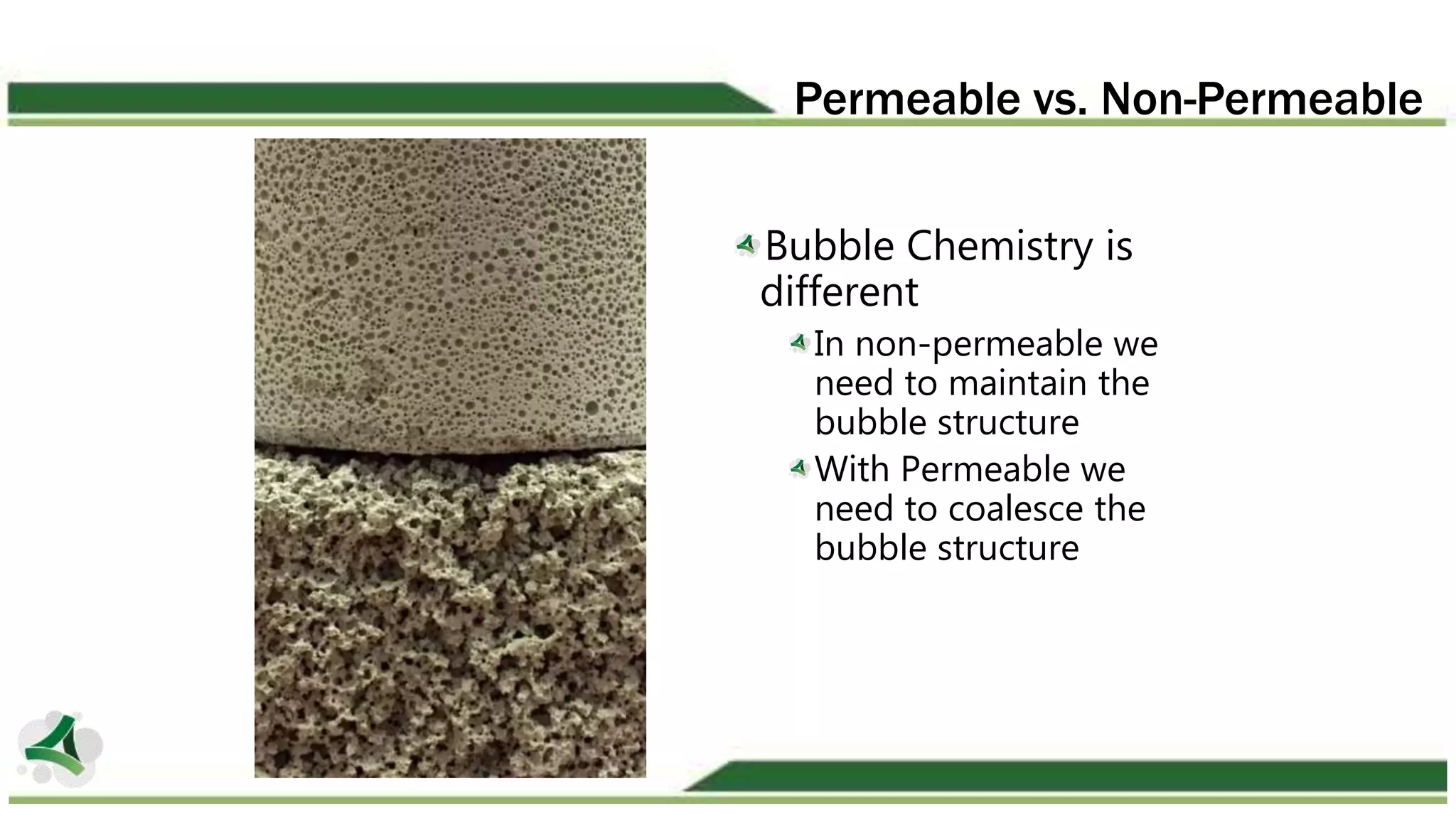

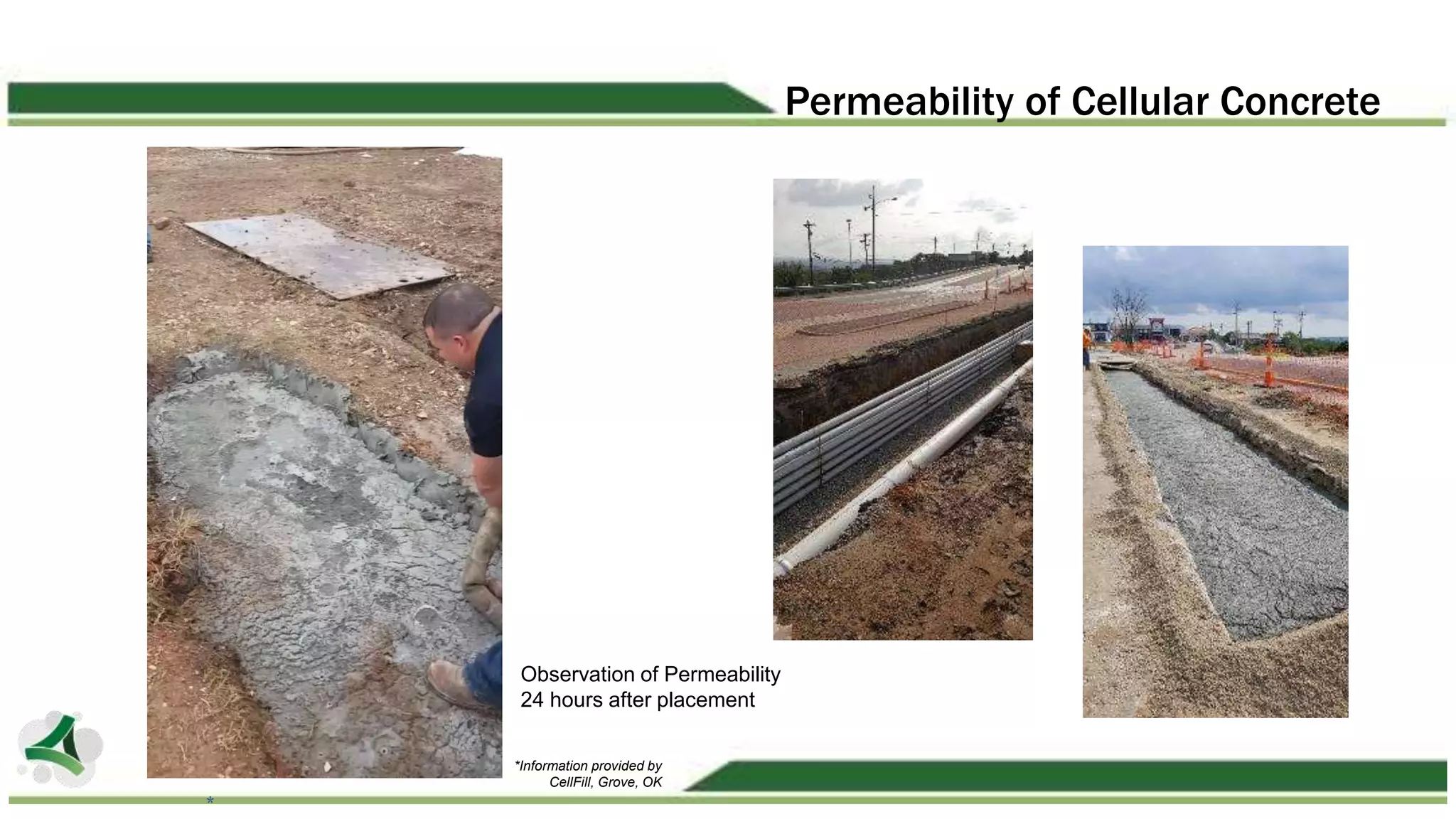

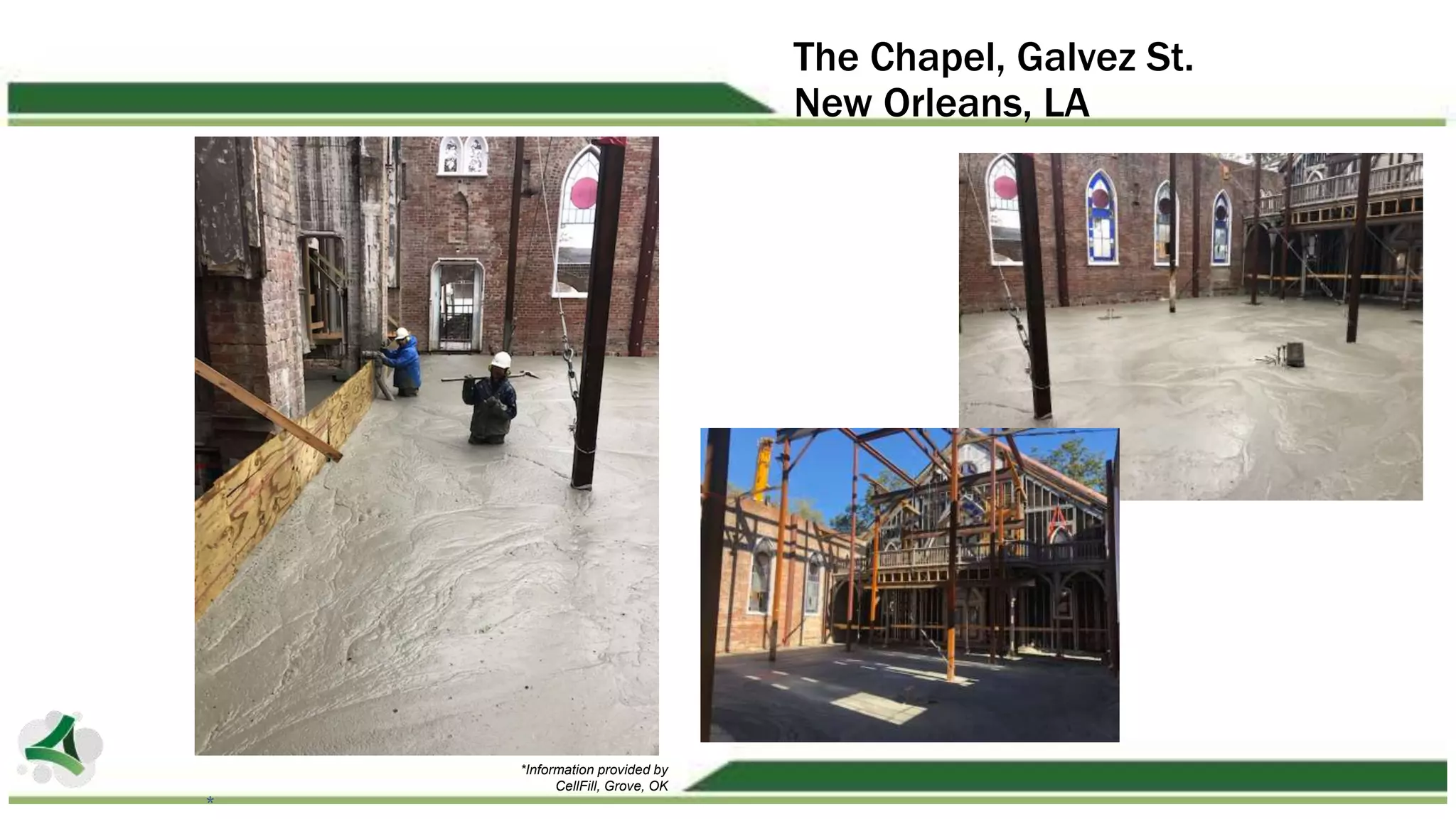

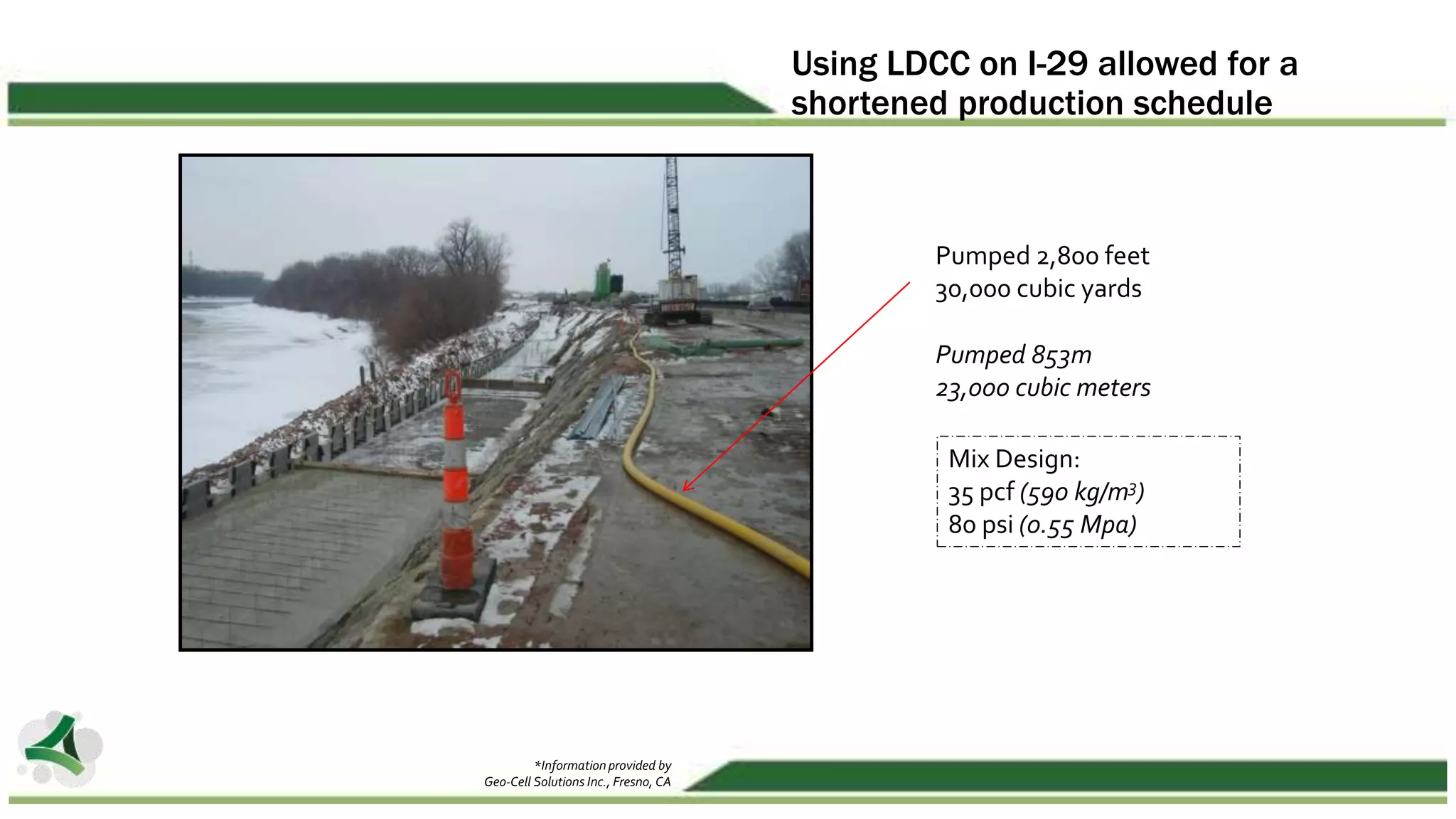

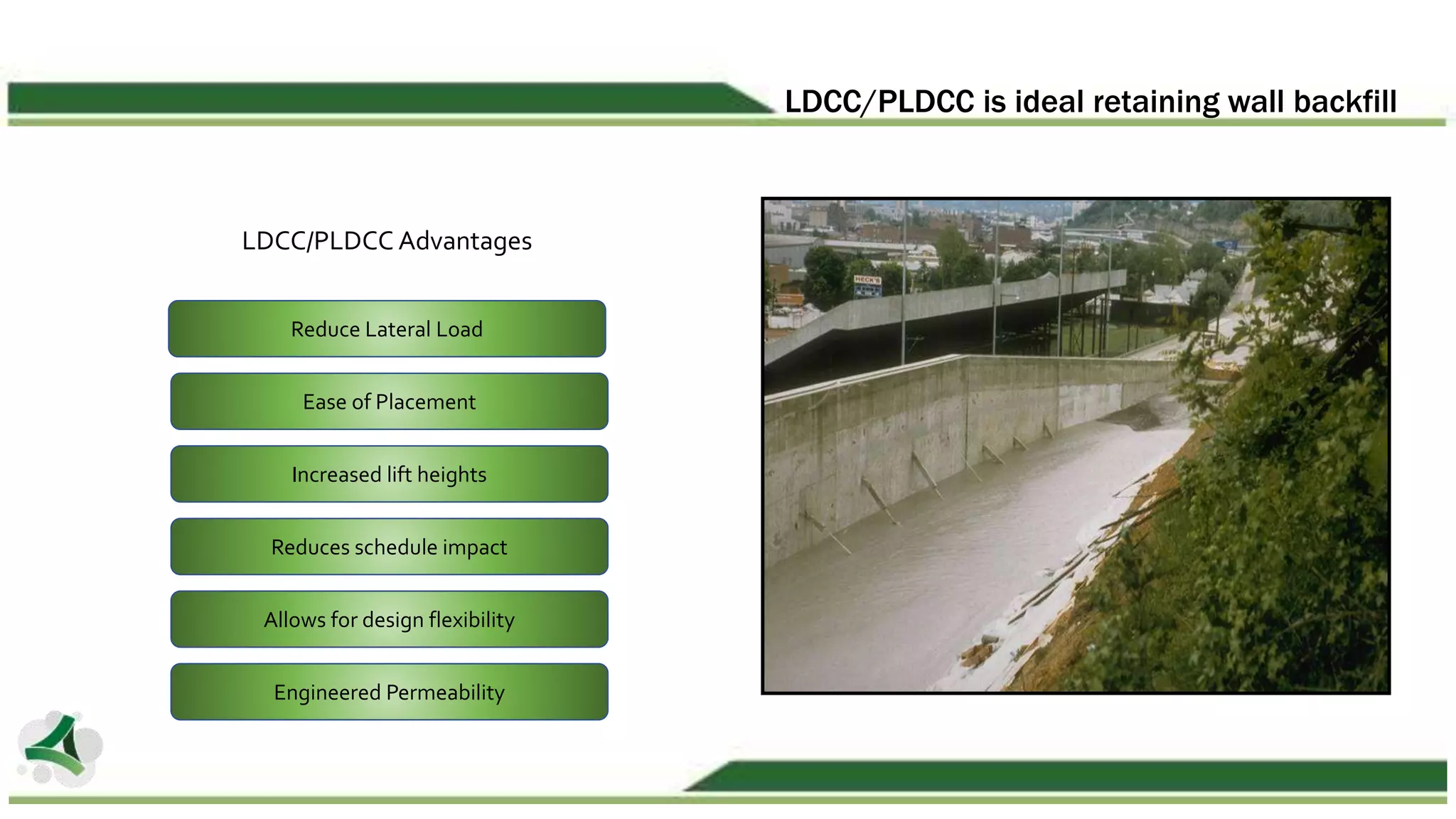

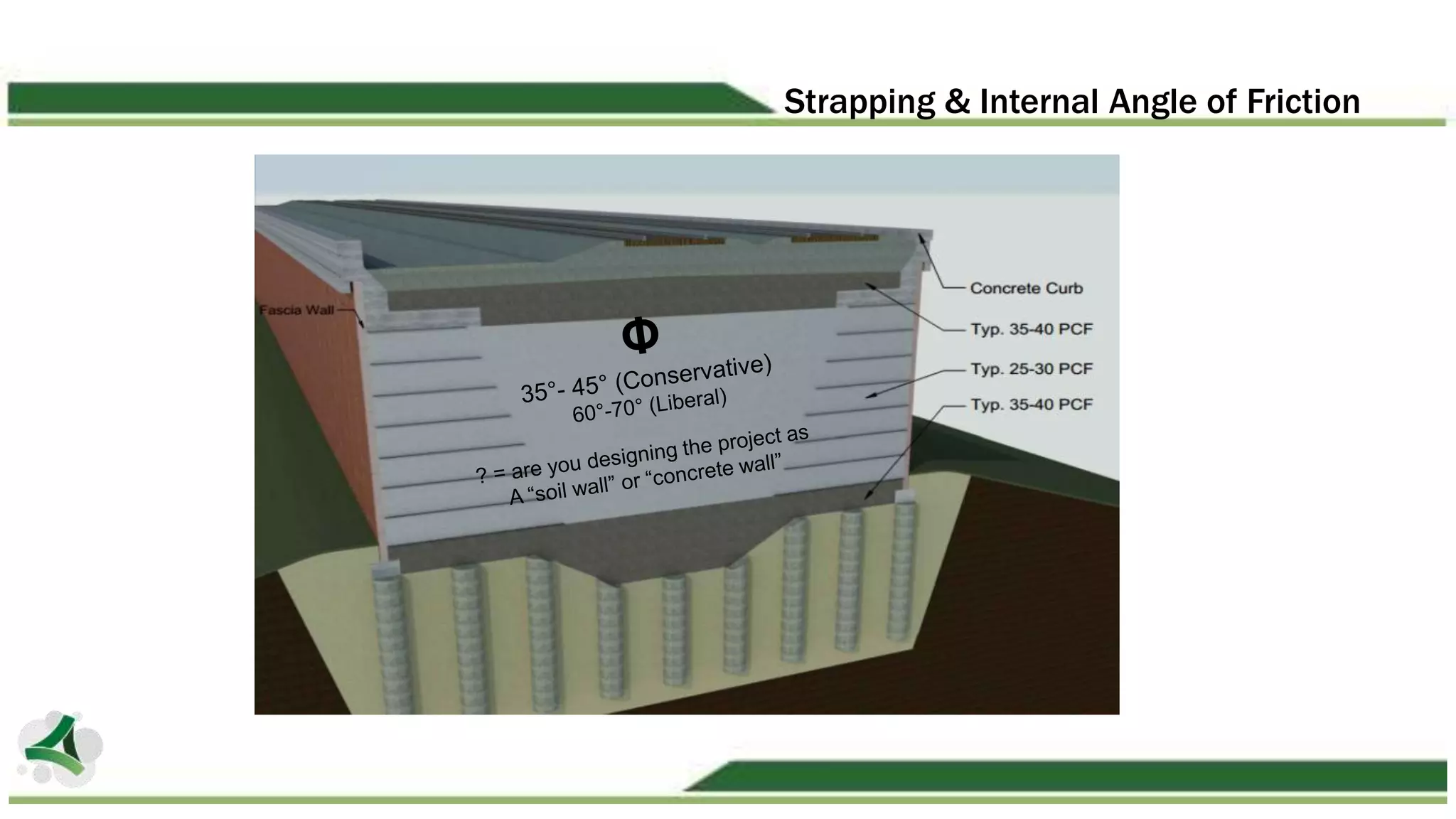

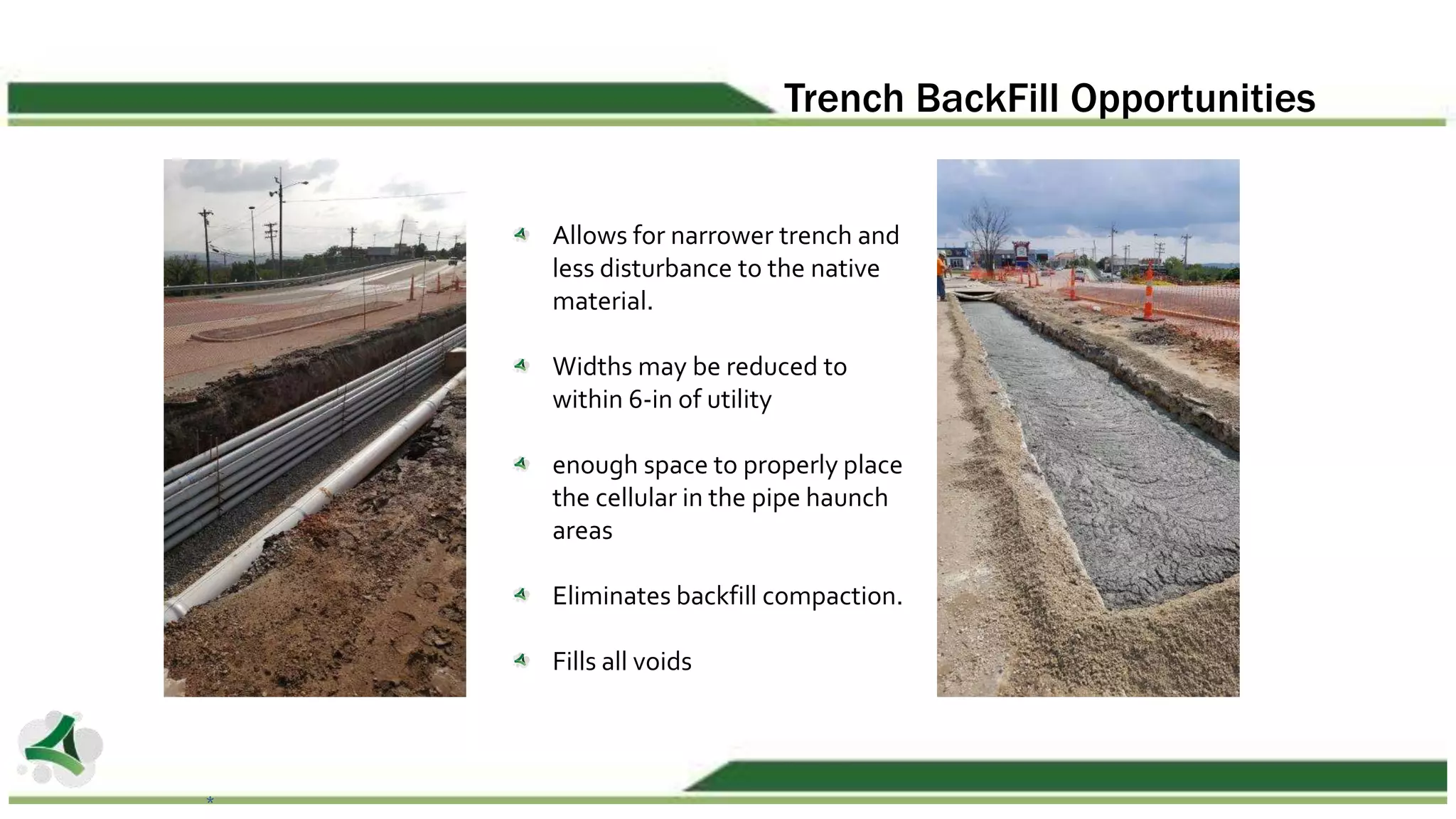

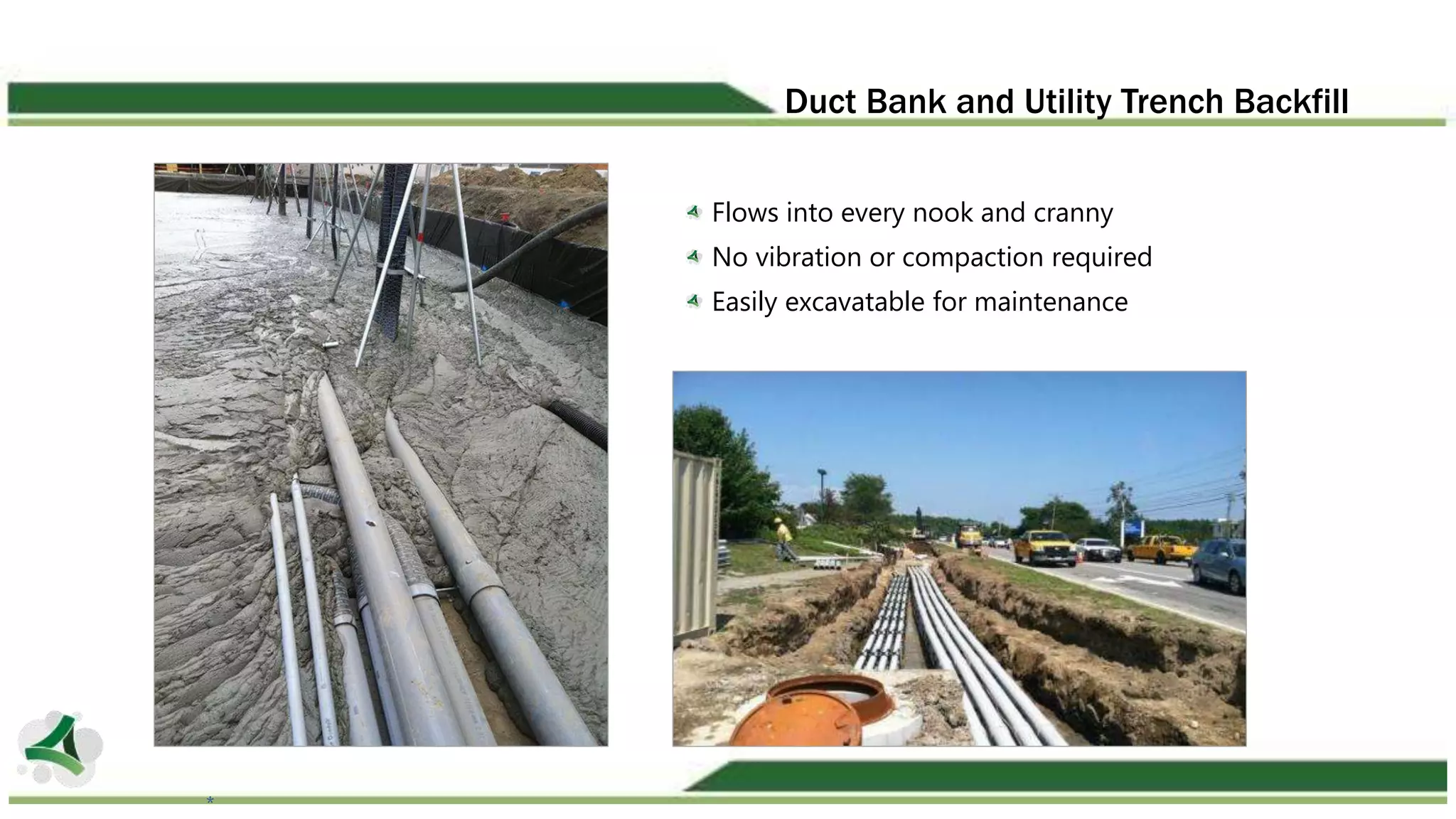

LDCC is a lightweight cellular concrete made with cement, water, and preformed foam to produce a hardened material with a density of 50 lbs or less per cubic foot. It replaces coarse aggregate with air bubbles, making it flowable and self-compacting for rapid placement into structures. LDCC comes in permeable and non-permeable varieties and has a broad range of applications including backfill, trench filling, and retaining walls due to its versatility, durability, and environmental friendliness.