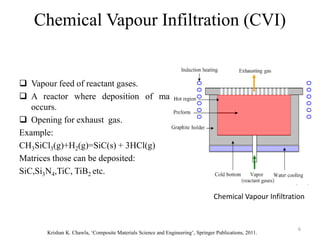

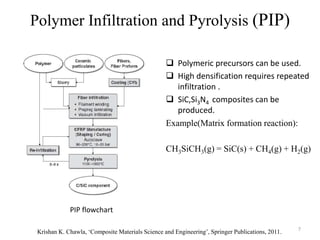

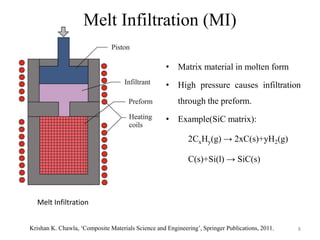

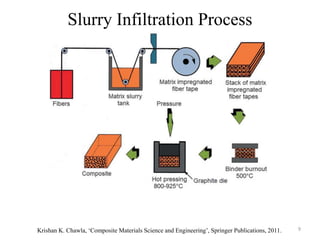

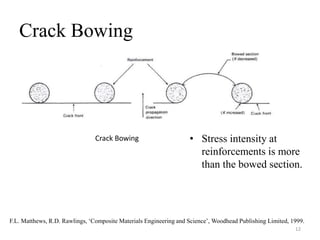

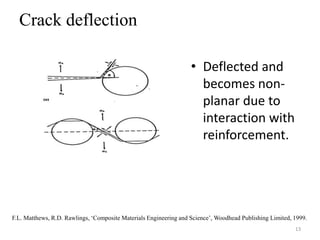

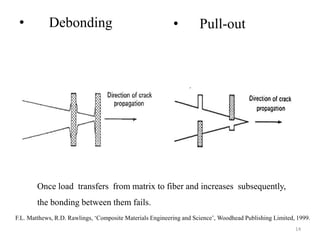

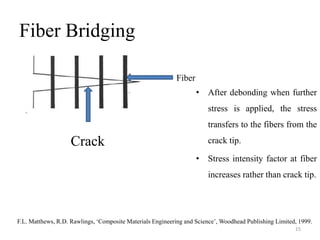

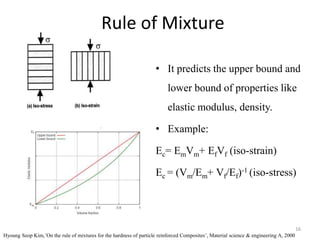

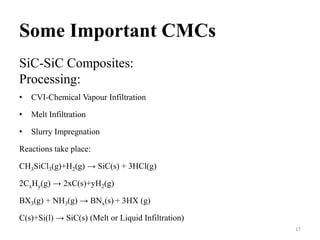

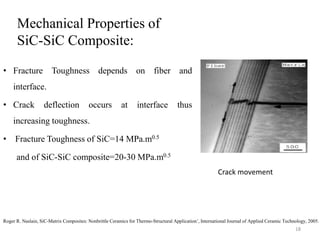

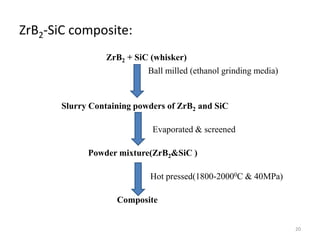

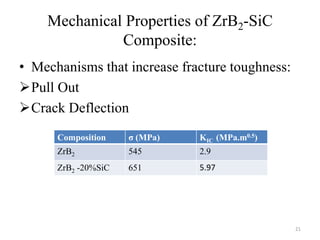

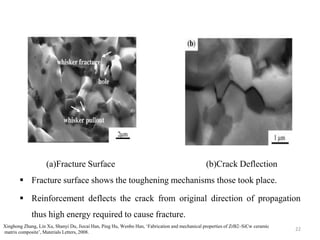

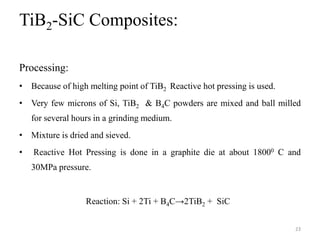

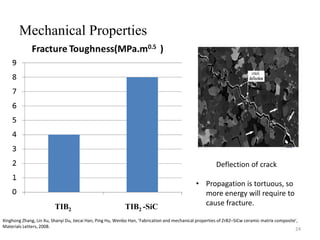

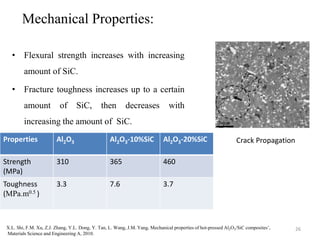

The document discusses ceramic matrix composites (CMCs), including the materials and processing methods used to produce them. It describes common matrix materials like Al2O3 and SiC and reinforcements like fibers and whiskers. Popular fabrication techniques are outlined, such as chemical vapor infiltration, polymer infiltration and pyrolysis, melt infiltration, and slurry infiltration. The mechanical properties of CMCs are summarized, focusing on fracture toughness which is improved through mechanisms like crack deflection and fiber pull-out. Specific CMC systems analyzed include SiC-SiC, ZrB2-SiC, TiB2-SiC, and Al2O3-SiC composites.