This document summarizes a study on safety hazard identification in the UK construction industry. It presents a procedure to calculate hazard identification indices (HII) for construction method statements. The study found maximum HII values of 0.899 or 89.9% for a nuclear project. Low HII values indicate knowledge, process, and procedure barriers that can be addressed by an IT tool called Total-Safety that helps standardize hazard identification and risk assessment methods. Total-Safety uses a task-based approach and database to improve information sharing across projects.

![Overview of Hazards and

Accident Causation

Hazards effect

Fatal accident

Severity=max

Accident

Severity>0

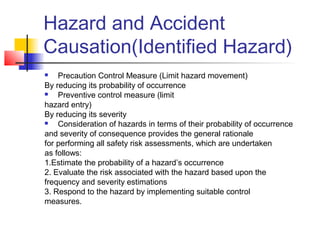

Precaution Control Measure

(Limit hazard movement)

Preventive control measure]

(limit hazard entry)

Hazard](https://image.slidesharecdn.com/safety-hazard-identification-on-construction-projects-140319105455-phpapp01/85/Safety-hazard-identification-on-construction-projects-5-320.jpg)