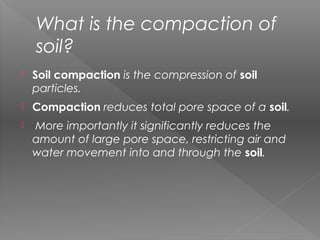

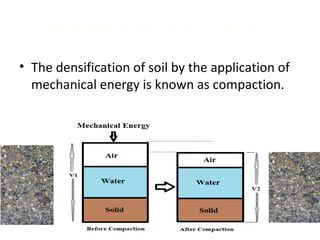

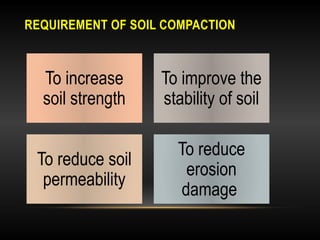

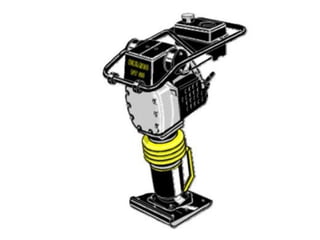

The document discusses soil compaction and various types of compaction equipment, highlighting their functions and suitable applications. It details different equipment such as smooth wheel rollers, sheep foot rollers, pneumatic rollers, and various vibrators for concrete consolidation. Additionally, it describes the role of compacting equipment in enhancing soil stability, reducing permeability, and preventing erosion.